6

Teel Operating Instructions and Parts Manual

3P740A, 4P037, 4P038, 4P039 and 4RJ96A

Teel One, Two, and Three Stage

Vertical Jet Pumps

®

E

N

G

L

I

S

H

Installation

REPLACING AN EXISTING PUMP

NOTE: For proper performance, pump

MUST be matched to ejector and to

well depth. See Tables I through IV,

Pages 3, 4, and 5, for information

about correct ejector packages and

nozzle/venturi combinations to use at

your well depth.

1. Long runs and many fittings

increase friction and reduce flow.

Locate pump as close to well as

possible: use as few elbows and

fittings as possible.

2. Be sure well is clear of sand. Sand

will plug the pump and void the

warranty.

3. Protect pump and all piping from

freezing. Freezing will split pipe,

damage pump, and void the

warranty. Check locally for frost

protection requirements (usually

pipe must by 12” below frost line

and pump must be insulated).

4. Be sure all pipes and foot valve are

clean and in good shape.

5. Be sure there are no air pockets in

suction pipe.

6. Be sure there are no leaks in suction

pipe. Use Teflon tape or Plasto-Joint

Stik

1

to seal pipe joints.

7. Match pump to well.

IMPORTANT: Flow into well must at

least equal flow out through pump!

8. Unions installed near pump and

well will aid in servicing. Leave

room to use wrenches.

1

Lake Chemical Co., Chicago, Illinois

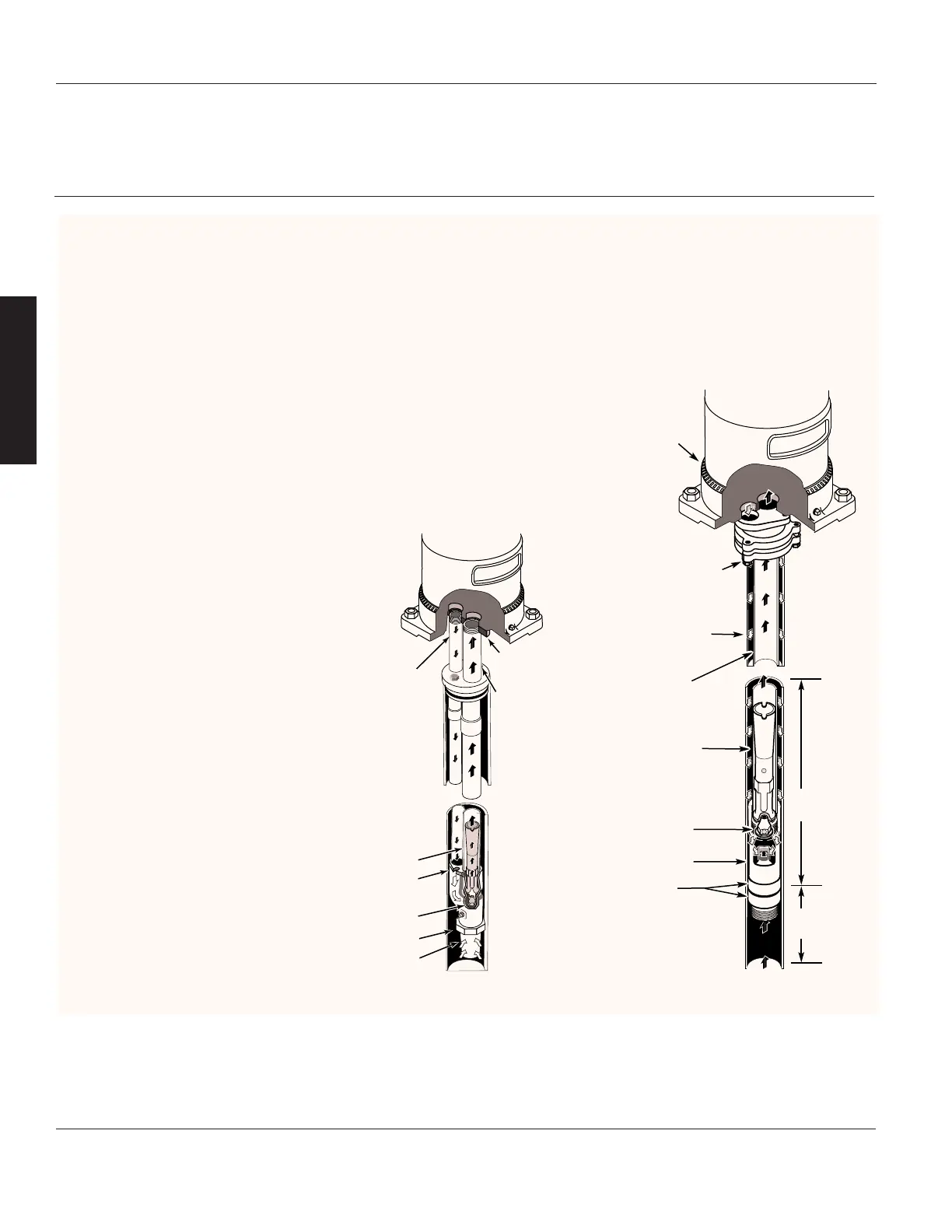

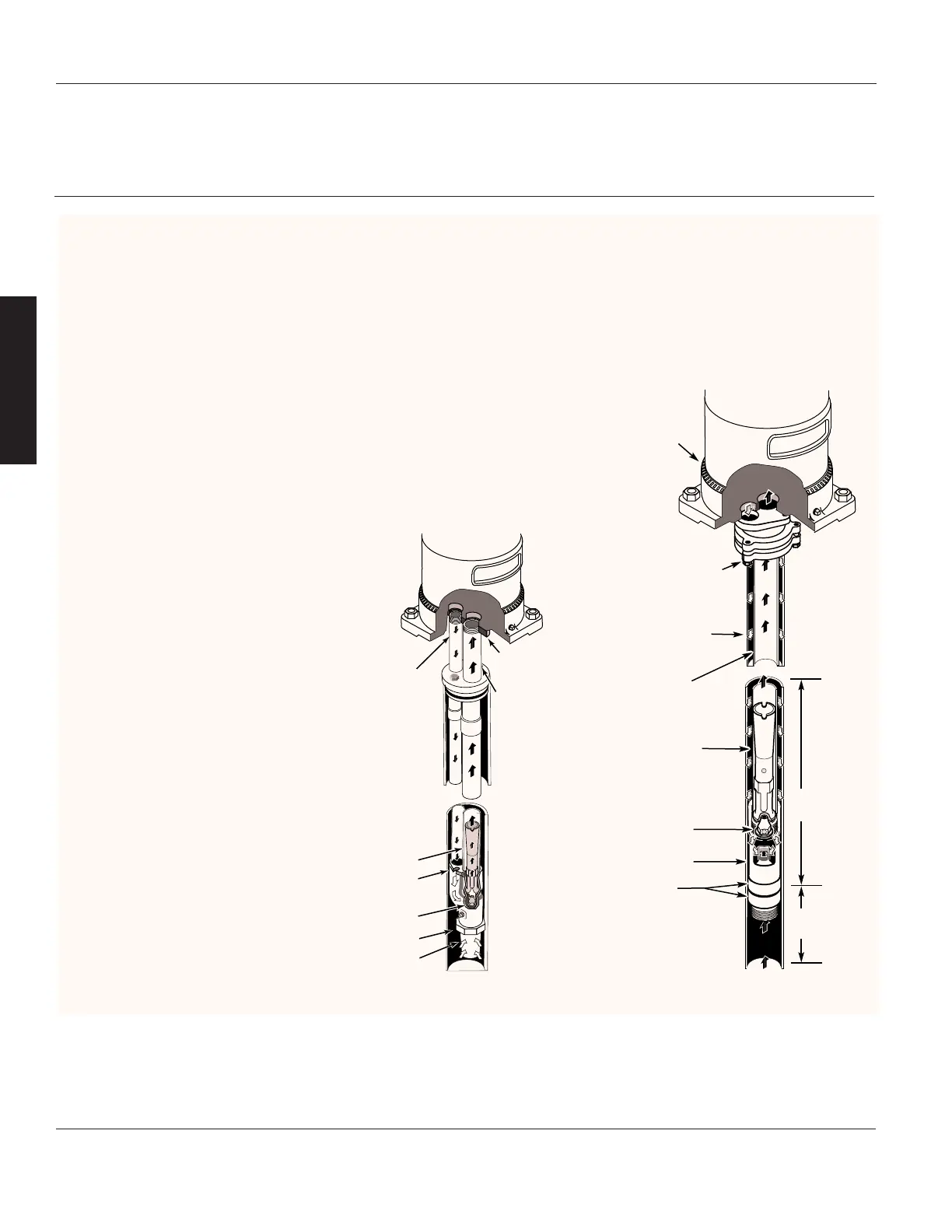

PIPING IN THE DEEP WELL

See Figures 1 and 2.

NOTE: Deep well installations are

either single pipe (2” wells) or double

pipe (4” and larger wells). In a double

pipe installation, with pipes of unequal

size, the larger pipe is the suction pipe

and the smaller pipe is the drive pipe

(1 and 1

1

⁄2 HP pumps on very deep wells

may use suction and drive pipes of the

same diameter).

Plastic pipe is ideal for double pipe

installations. Due to its light weight, it

is easy to handle and does not usually

require a block and tackle for

installation and removal.

PLASTIC PIPE INSTALLATION –

DOUBLE PIPE (SEE FIGURE 1)

NOTE: Use Teflon tape on all male

threads on plastic pipe and fittings to

prevent air leaks in suction piping.

1. Inspect ejector to make sure that

nozzle and venturi openings are

clean and clear.

JET NO.

Loading...

Loading...