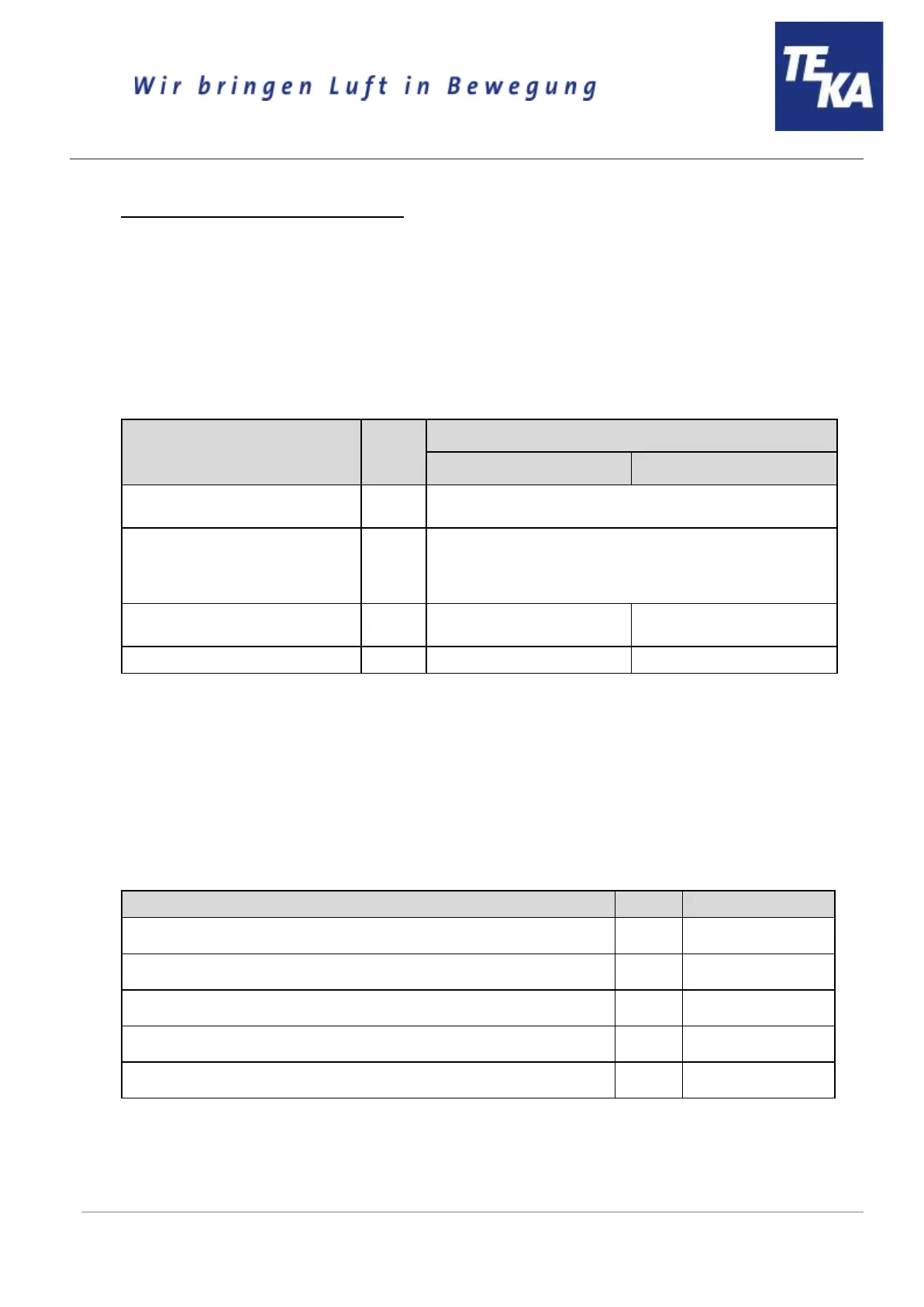

14. Maintenance intervals

14.1. Usage-related maintenance

The described maintenances become necessary through the demands of the system operations. The

maintenance intervals are recommendations. Depending on the application (multi-shift operation, dust

generation, ...) it may make sense for the operator to change the maintenance intervals.

Maintenance work must always be documented by means of a protocol.

The approach of the maintenance measures is described in chapter "Maintenance".

determined by the operator

Cleaning the filter cartridges

The cleaning of the filter cartridges is automatically carried out

by the filter unit and thus is not subject to a maintenance interval.

Replacing the filter cartridges

The saturation of the filter cartridges is automatically monitored

by the filter unit and thus is not subject to a maintenance interval.

The filter unit triggers an alarm when a replacement of the filter

cartridges is necessary.

Emptying the dust collecting tank (or

check of fill level)

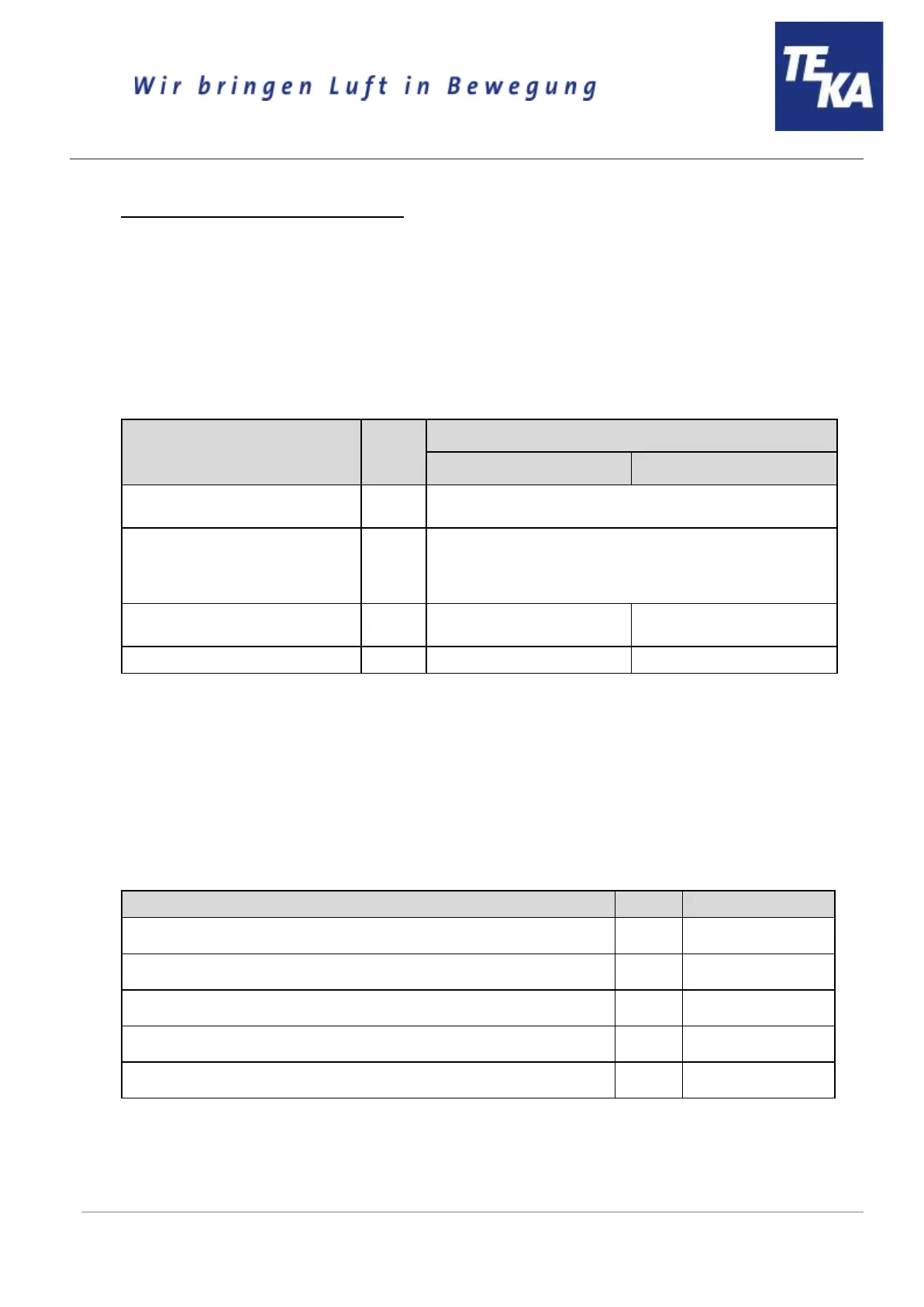

14.2. General maintenance

The described maintenances are independent from the demands of the system operations.

The operator is obliged to carry out repeated inspections and functional tests according to national

regulations. If not otherwise covered by national regulations, the described maintenance intervals must

be respected.

Maintenance work must always be documented by means of a protocol.

Visual inspection of the device

Visual inspection of the pipelines for dust deposits

Visual inspection of the pneumatic pipes

Functional test of the device

Electrical test of the electrical lines and earthing connections

BA_Airtech_P10_IFA_190319_EN

Loading...

Loading...