Calibration—475

b. Adjust the CH 1 POSITION control to horizontally

center the dot.

c. Set the Test Oscilloscope: TIME/DIV switch to 1 ms,

VOLTS/DIV switch to 0.5 V, and AC-GND-DC switch to

DC.

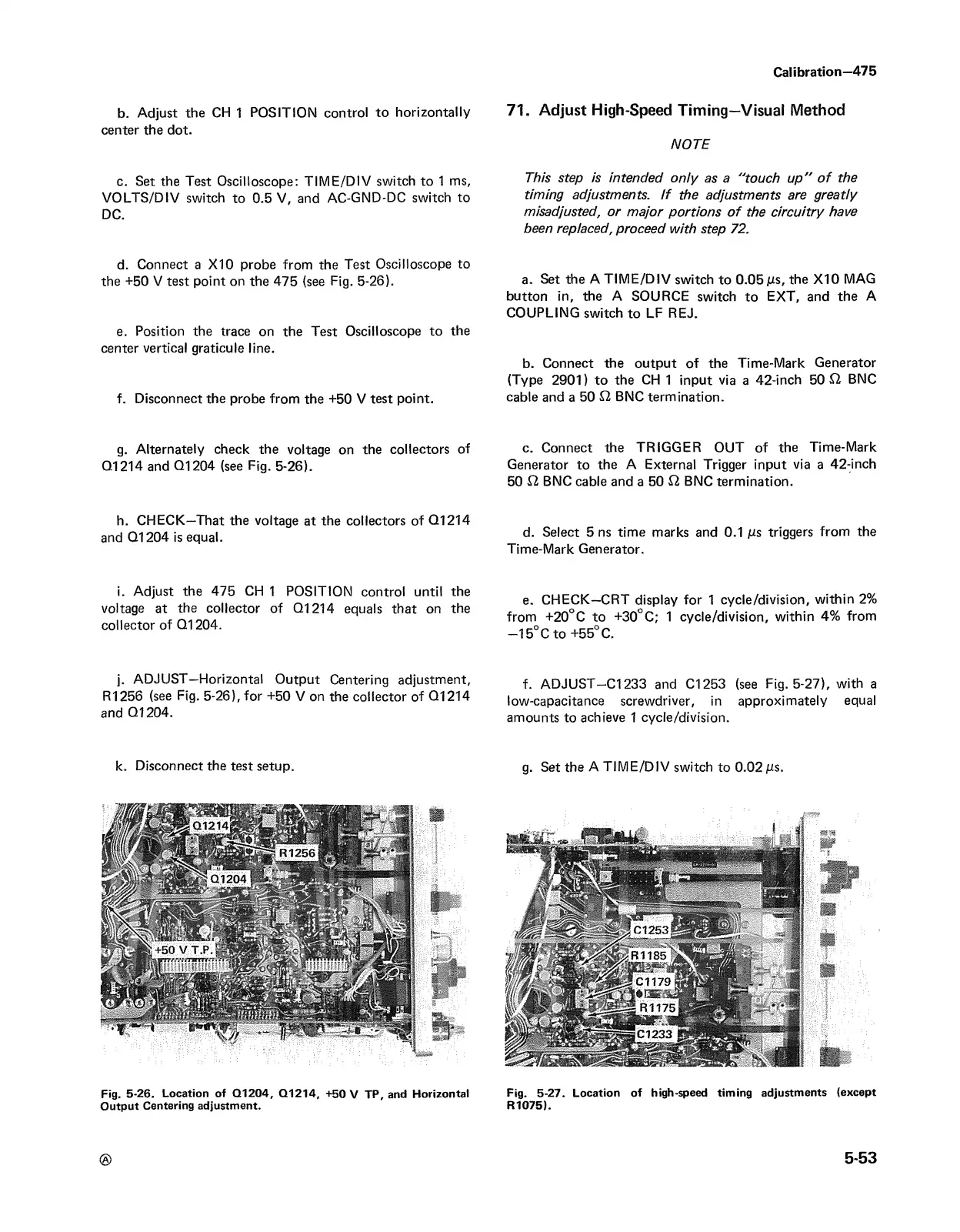

d. Connect a X I0 probe from the Test Oscilloscope to

the +50 V test point on the 475 (see Fig. 5-26).

e. Position the trace on the Test Oscilloscope to the

center vertical graticule line.

f. Disconnect the probe from the +50 V test point.

g. Alternately check the voltage on the collectors of

Q1214 and Q1204 (see Fig. 5-26).

h. CHECK—That the voltage at the collectors of G1214

and Q1204 is equal.

i. Adjust the 475 CH 1 POSITION control until the

voltage at the collector of Q1214 equals that on the

collector of Q1204.

j. ADJUST—Horizontal Output Centering adjustment,

R1256 (see Fig. 5-26), for +50 V on the collector of G1214

and G1204.

71. Adjust High-Speed Timing—Visual Method

NOTE

This step is intended only as a "touch u p" o f the

timing adjustments. If the adjustments are greatly

misadjusted, or major portions o f the circuitry have

been replaced, proceed with step 72.

a. Set the A TIME/DIV switch to 0.05 jus, the X I0 MAG

button in, the A SOURCE switch to EXT, and the A

COUPLING switch to LF REJ.

b. Connect the output of the Time-Mark Generator

(Type 2901) to the CH 1 input via a 42-inch 50 £2 BNC

cable and a 50 £2 BNC termination.

c. Connect the TRIGGER OUT of the Time-Mark

Generator to the A External Trigger input via a 42-inch

50 El BNC cable and a 50 El BNC termination.

d. Select 5 ns time marks and 0.1 jus triggers from the

Time-Mark Generator.

e. CHECK—CRT display for 1 cycle/division, within 2%

from +20°C to +30°C; 1 cycle/division, within 4% from

—15°C to +55° C.

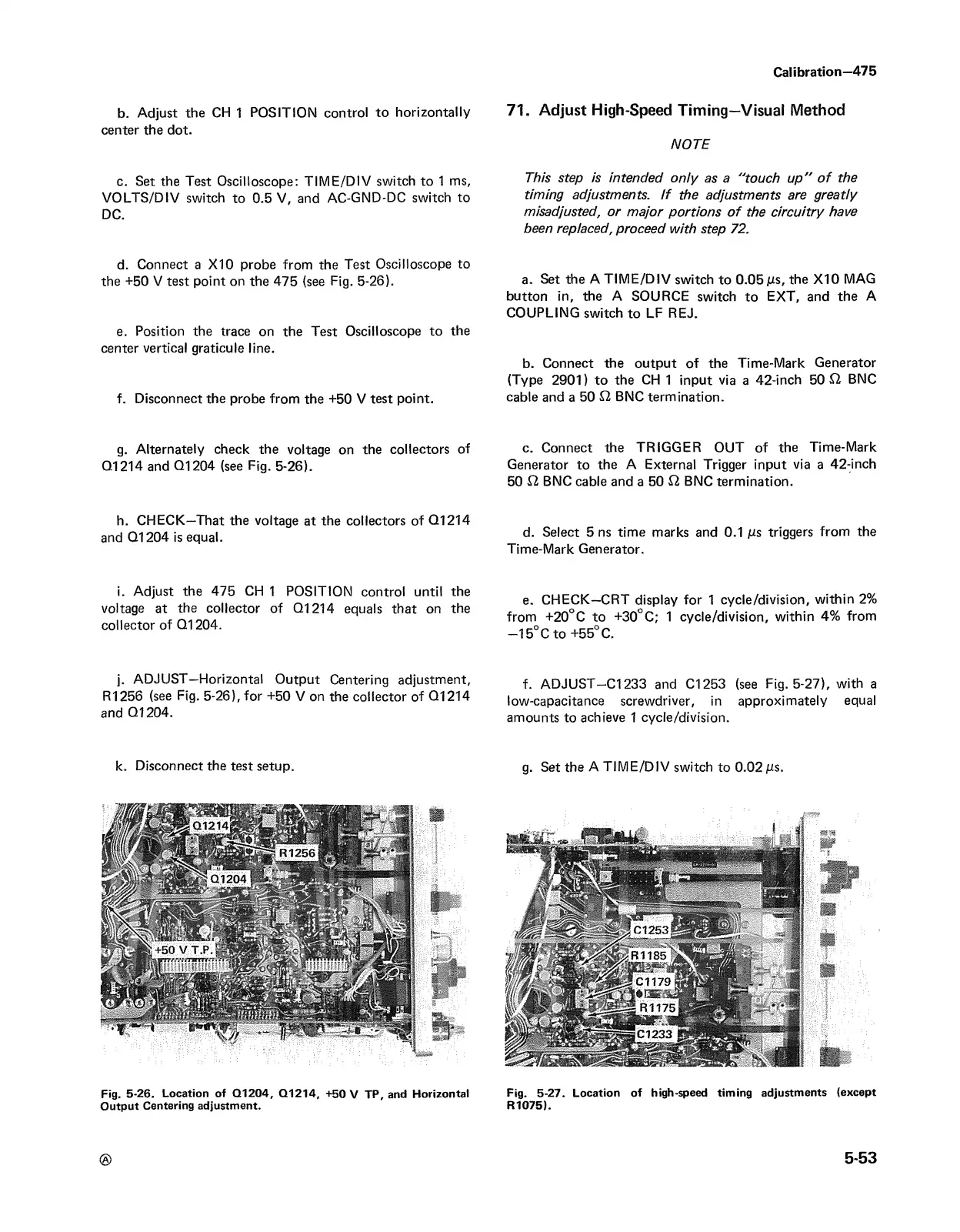

f. ADJUST—C l233 and C l253 (see Fig. 5-27), with a

low-capacitance screwdriver, in approximately equal

amounts to achieve 1 cycle/division.

Fig. 5-26. Location of Q1204, Q1214, +50 V TP, and Horizontal Fig. 5-27. Location of high-speed timing adjustments {except

Output Centering adjustment. R1075).

®

5-53

Loading...

Loading...