4.0 SM6 Airflow Sensor Installation

It is very important to position the AFA 500 or SM6 airflow sensor in the correct position to give long term stable reading

of the face velocity. Please read the INSTALLATION NOTES below and if in doubt contact us for further advice.

INSTALLATION NOTES :-

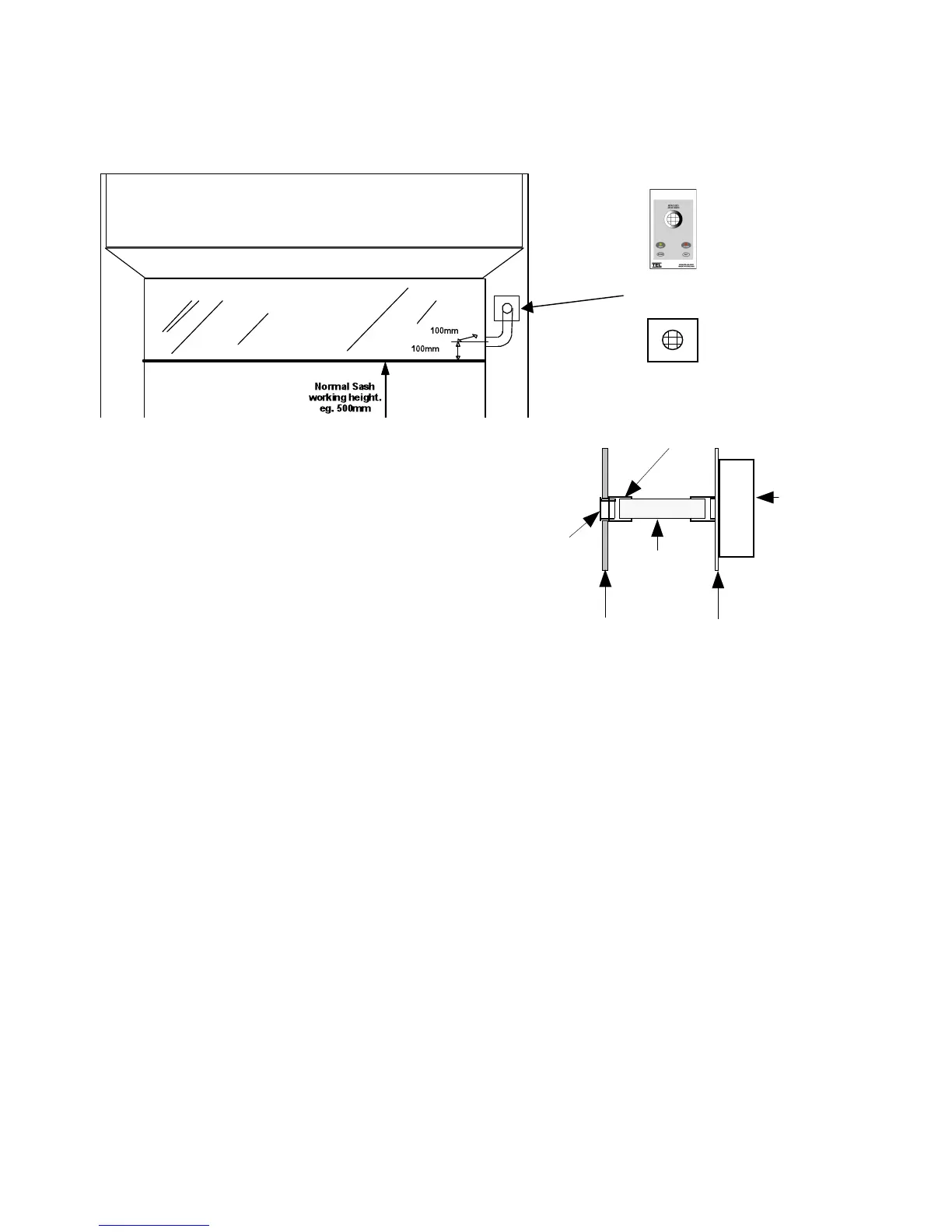

1. The AFA 500 or SM6 sensor must be positioned where it can " see " the room pressure of the laboratory.The back

connection spigot of the sensor is designed to accept a 25mm OD tube which should be connected to the inner

chamber of the fume hood. (This tube and fittings is known as the " vent kit " )

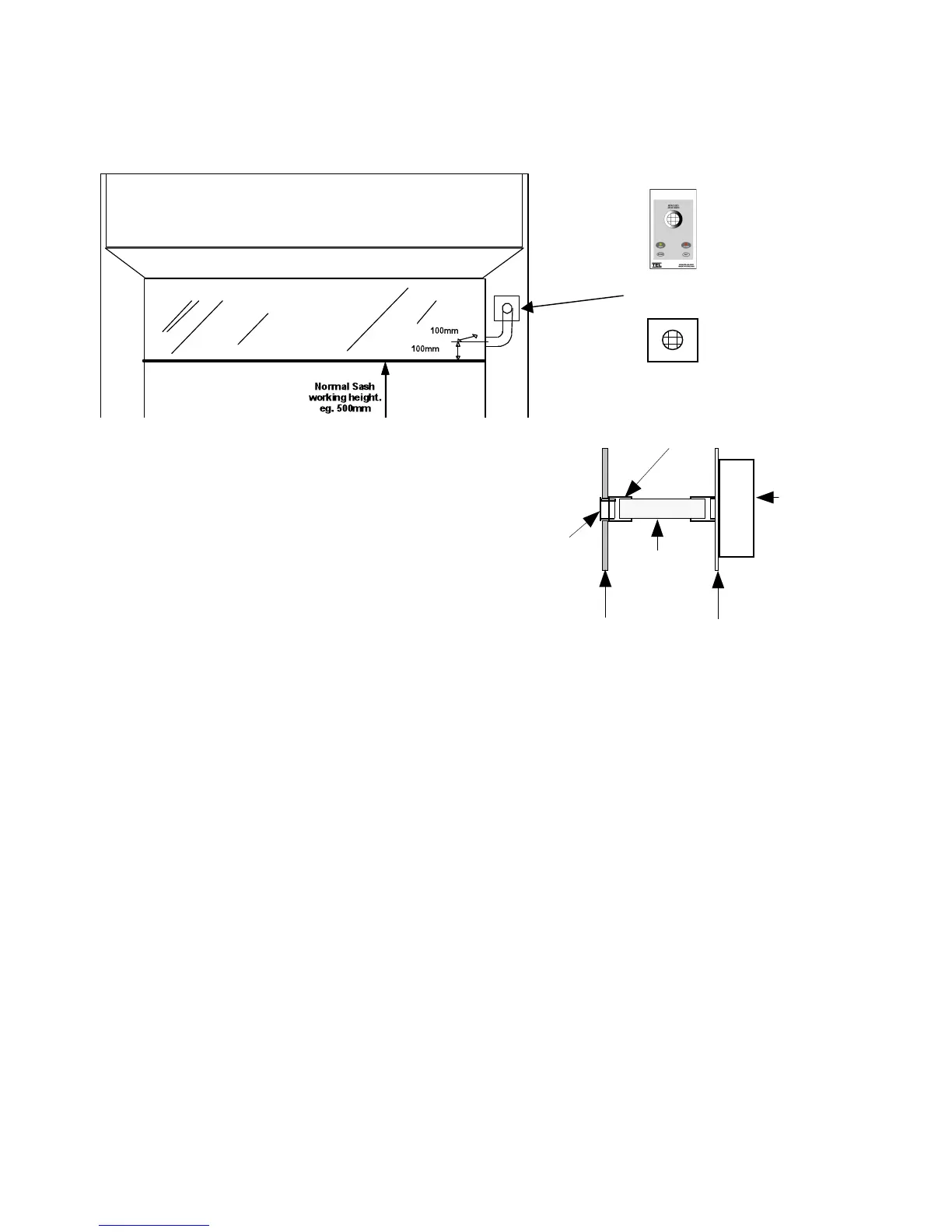

The ideal position for the end of the 25mm tube for most fume hoods is 100mm back from the sash glass

and 100mm higher than the normal sash opening height through the inner side wall.

2. If possible mount the sensor on the front of the fume hood and use a short length of tube. Tube lengths of

more than 1metre or smaller diameter will restrict the airflow through the sensor. This will lead to too much

sensitivity being required to calibrate the unit which can lead to some instability of the reading or incorrect

readings at low velocitiesl.

3. For fume hoods with a single skin side wall or a double skin with a small gap between them it may not be

possible to achieve the ideal sensing position using a flexible tube.

With a single skin side wall it is possible to fix the sensor on the outside of the fume hood and connect directly

to the inner chamber in the ideal position. This method can only be used for up to two fume hoods when they

are positioned side by side ( using the two outer walls ).

An alternative method is to mount the sensor on the front of the fume hood and connect using a short flexible

tube to a rigid wall tube attached to the inner side wall. The open end of this rigid wall tube should be positioned in

the ‘ideal position’ ie. 100mm back from the sash and 100mm higher than the normal sash opening.

Fume hoods with a high internal height can present a difficulty because the tube length to reach the ideal

position may be longer than 1 metre. In this case it is better to use a tube no longer than 1 metre which may result

in a sensing position higher than the ideal.

When fitting a sensor to a ’narrow wall’ fume hood for the first time it may be necessary to try various

combinations of rigid and flexible tube to find the best combination and position.

4. The sensor should not be mounted in a position were it is subject to draughts from the laboratory air input or

Loading...

Loading...