Page 9 of 12

Auto-tuning

The auto-tuning process is performed near the set point.

The process will oscillate around the set point during

the tuning process. Set the set point at a lower value if over-

shooting beyond the normal process value is likely to cause

damage.

Auto-tuning is applied in cases of:

• Initial setup for a new process

• The set point is changed substantially from the previous

auto-tuning value

• The control result is unsatisfactory

Operation:

1. The system has been installed normally.

2. Set the correct values for the setup menu of the unit, but

don’t set a zero value for PB and TI, or the auto-tuning pro-

gram will be disabled. The LOCK parameter should be set

at NONE.

3. Set the set point to a normal operating value, or a lower value

if overshooting beyond the normal process value is likely to

cause damage.

4. Press and hold until appears on the display.

5. Then press

again

for at least 5 seconds. The AT indicator

will begin to flash and the auto-tuning procedure begins.

NOTE: The ramping function, if used, will be disabled when

auto-tuning is taking place.

Auto-tuning mode is disabled as soon as either failure mode or

manual control mode is entered.

Procedures:

Auto-tuning can be applied either as the process is warming

up (cold start), or when the process has been in a steady state

(warm start). After the auto-tuning procedures are completed,

the AT indicator will cease to flash and the unit will revert to

PID control using its new PID values. The PID values ob-

tained are stored in the nonvolatile memory.

Auto-Tuning Error

If auto-tuning fails an ATER message will appear on the upper

display in the following cases:

• If PB exceeds 9000 (9000 PU, 900.0°F or 500.0°C),

• if TI exceeds 1000 seconds,

• if the set point is changed during the auto-tuning procedure.

Solutions to

1. Try auto-tuning once again.

2. Don’t change the set point value during the auto-tuning pro-

cedure.

3. Don’t set a zero value for PB and TI.

4. Use manual tuning instead of auto-tuning (see section 3-12).

5. Touch RESET key to reset message.

Manual Tuning

In certain applications auto-tuning may be inadequate for the

control requirements. You can try manual tuning for these ap-

plications.

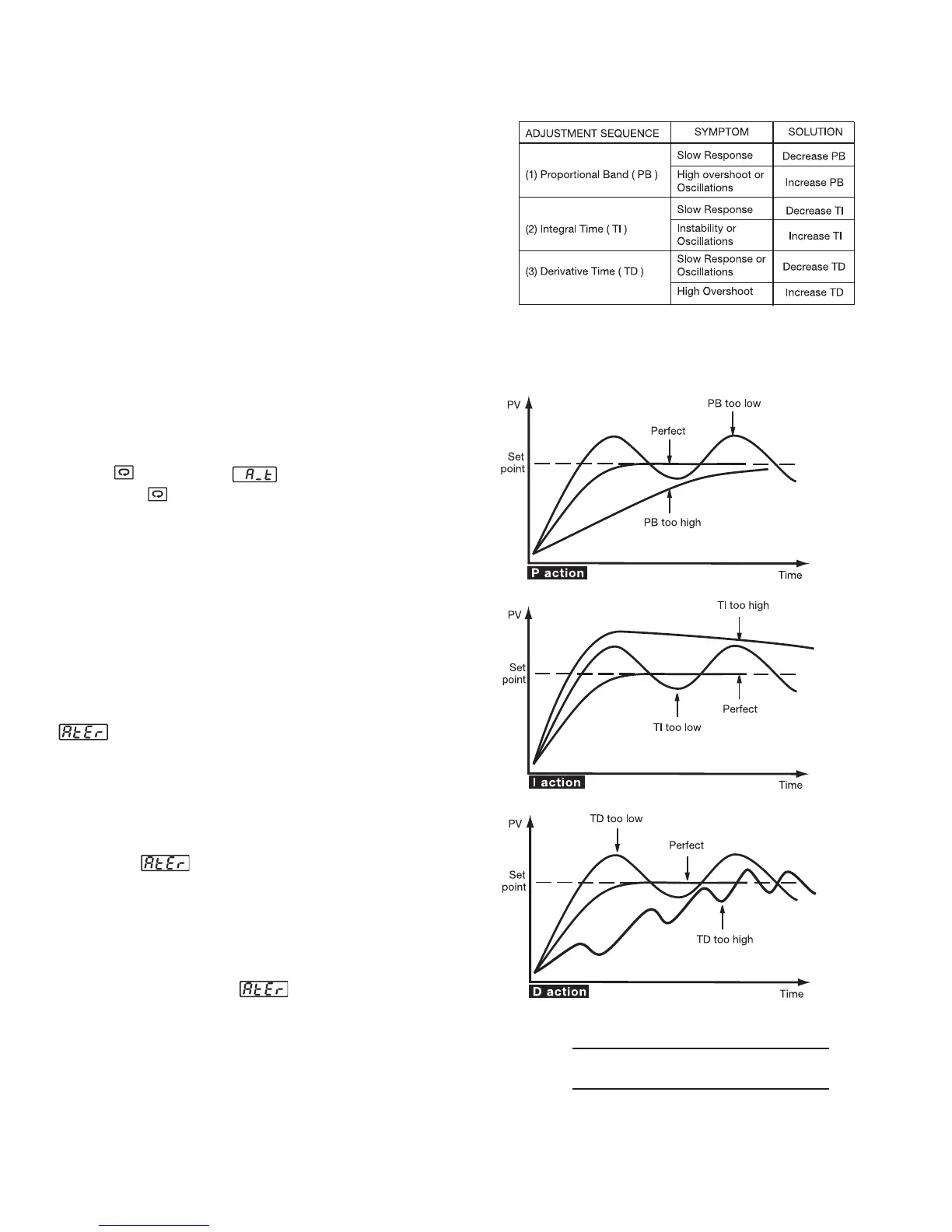

If the control performance using auto-tuning is still unsatis-

factory, the following rules can be applied for further adjust-

ment of PID values:

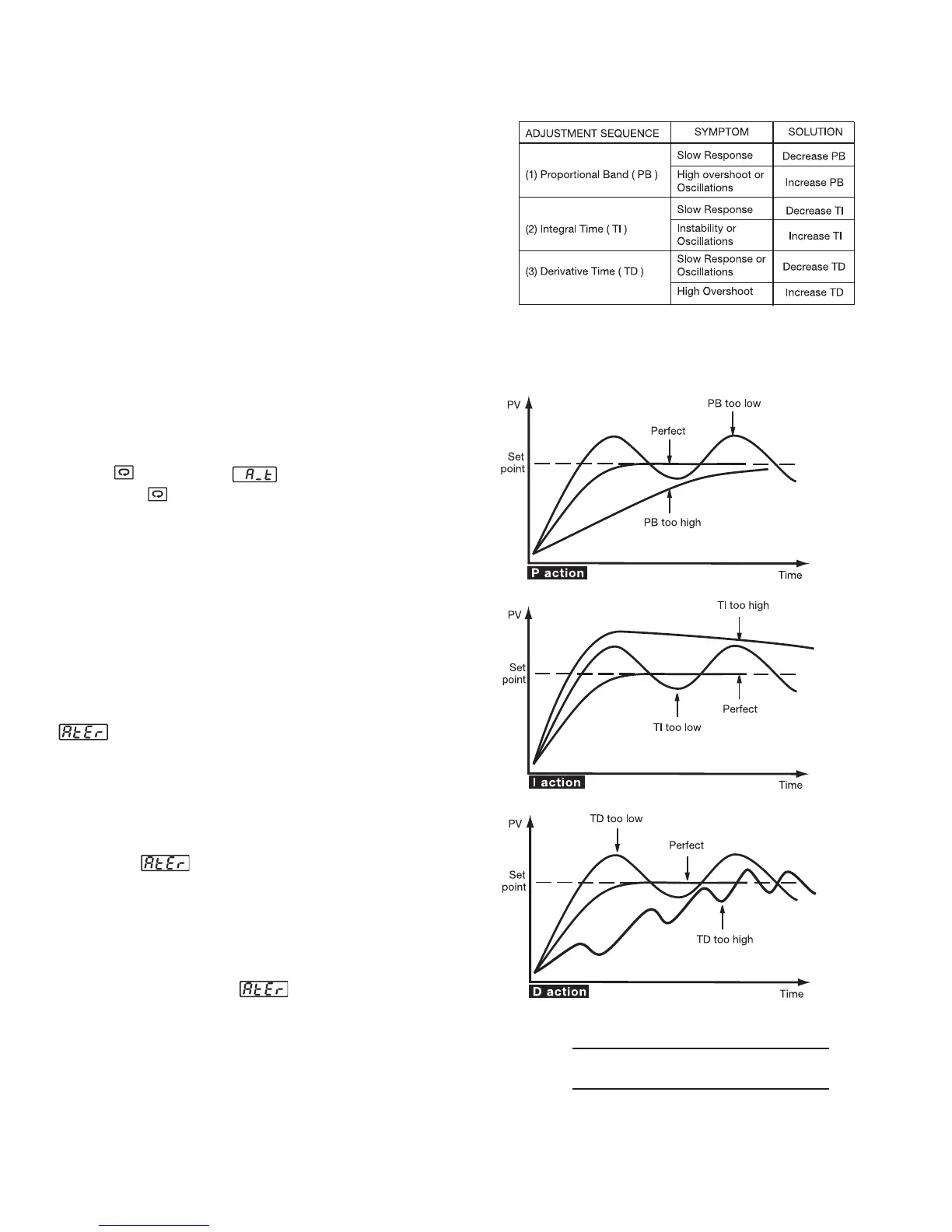

Figure 3.9 shows the effects of PID

adjustment on process response.

Figure 3.9 Effects of PID Adjustment

Table 3.2 PID Adjustment Guide

Loading...

Loading...