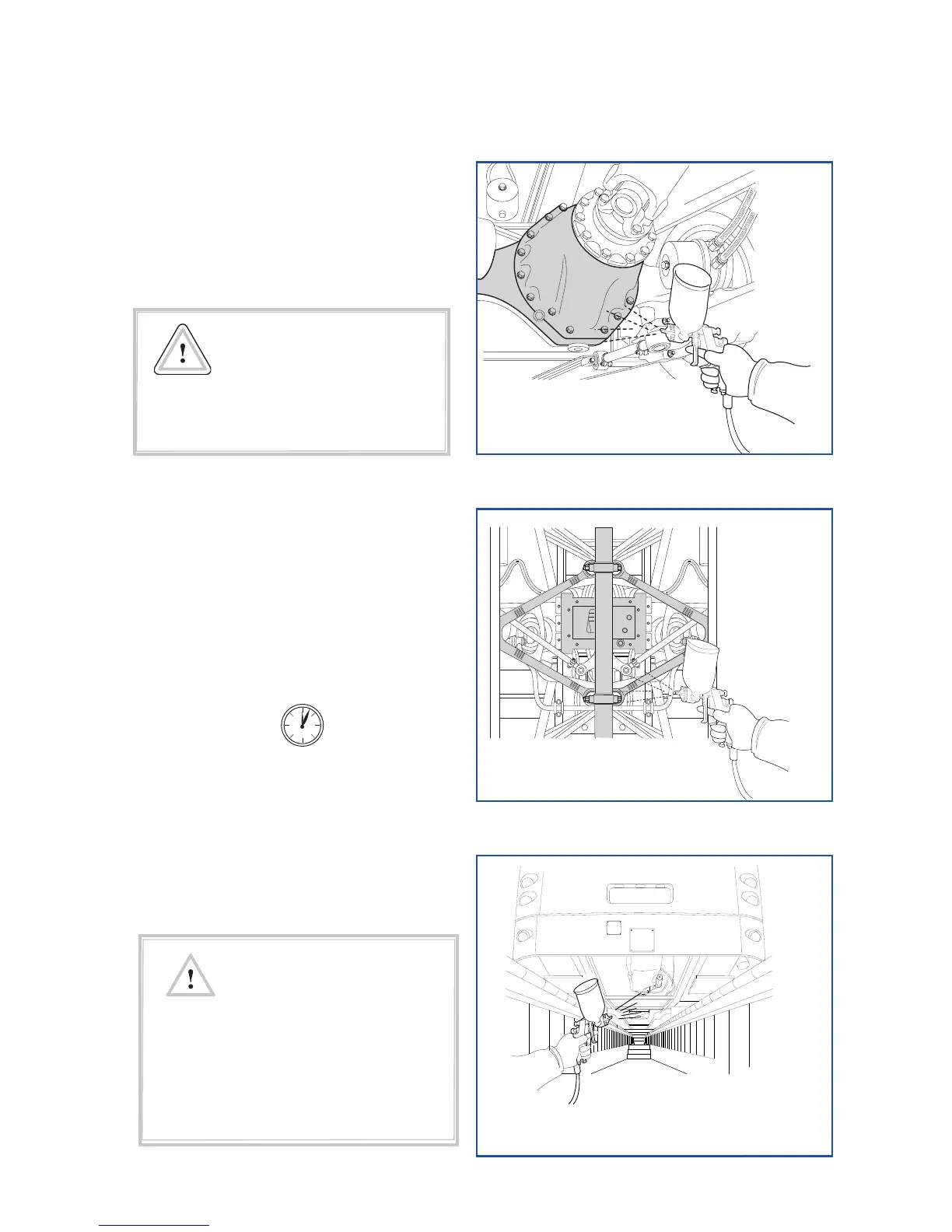

6.2 SCREW WAXING APPLICATION

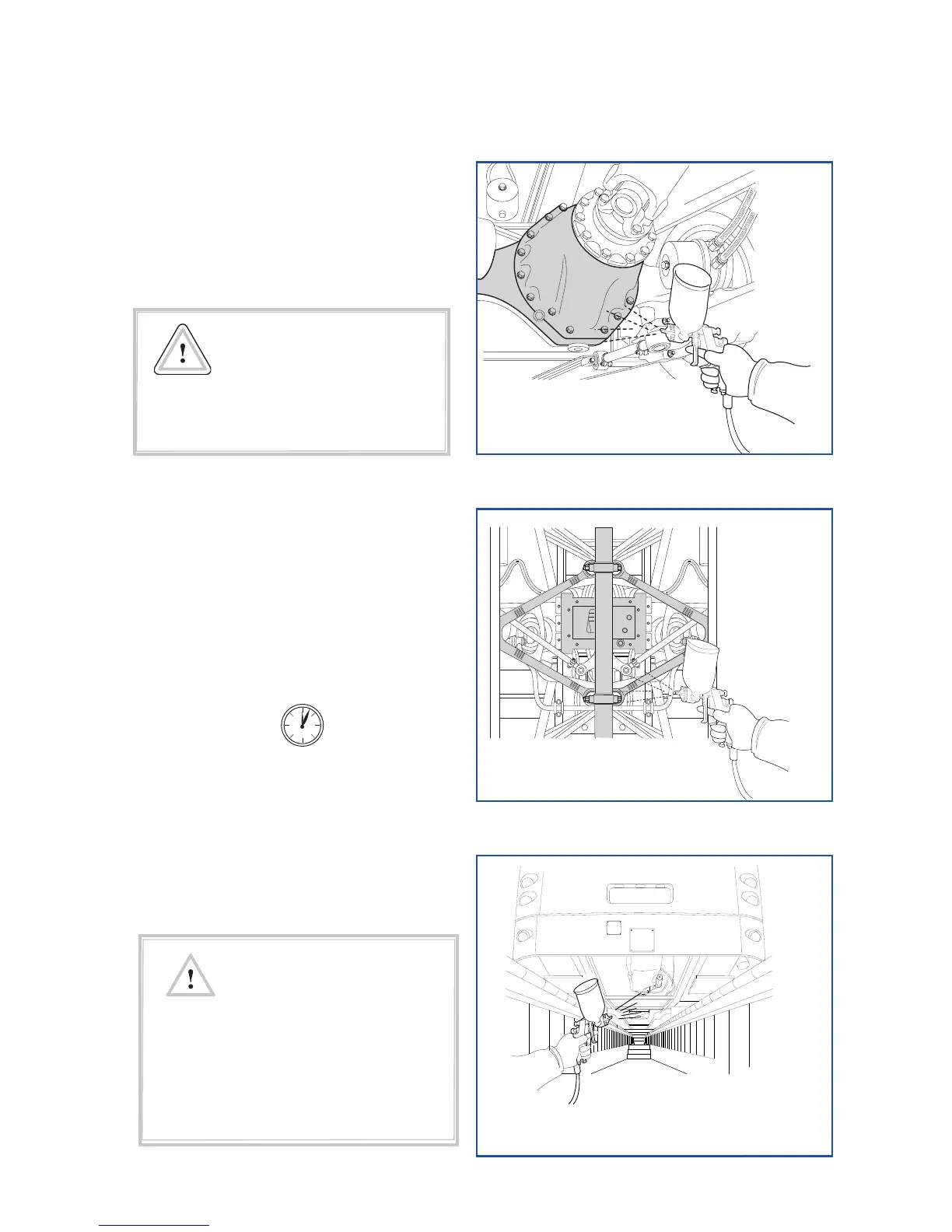

6.3 UNDERBODY COATING

All metal parts at the engine compartment

(inculuding heating cupper tubes and A/C

compressor, Exhaust mufer bracket etc.)

could be waxed with Efcoat WE439A1 Anti

Corrosive Material as shown in the gure.

1. Brush the corroded zone with wire

brush.

2. Clean the brushed area with a solvent

or thinner and dry it with a dry cloth.

3. Apply epoxy primer to the cleaned and

dried zones.

4. Wait 12 hours for primed surfaces to

be dried.

5. Apply underbody coating (Dinitrol

4942).

6. PROCEDURE FOR CHASIS (ZONE B)

waxing

12

CAUTION

CAUTION

- DO NOT use any heat sources to dry

the underbody epoxy primer.

- To avoid any cooling problem,

differential coating thickness should

be 200-250 micron.

Take necesssary re precautions

when working mufer line, screws

and components of heating system.

Loading...

Loading...