SM 1667 1-99

Engine - Engine and Mounting

Section 110-0030

6

Note: before starting the engine, follow the steps

below to make sure the engine receives correct

lubrication. Lack of lubrication will damage the

engine.

a. Disconnect the electrical wire from the fuel pump

solenoid valve.

b. Switch on the ignition and rotate the crankshaft

using the starter motor, until oil pressure appears on

the pressure gauge or the warning light goes out.

c. Connect the electrical wire to the fuel pump

solenoid valve.

Start the engine and operate at idle speed to inspect

for leaks at the filters and oil drain plug. Shut off the

engine, wait approximately five minutes to let the oil

drain back to the sump and check the oil level again.

Add oil as necessary to bring the level to the high (H)

mark on the dipstick.

Crankcase Breather - Check and clean the

crankcase breather hose. Remove the breather hose

and check internally for obstructions or sludge

buildup. Clean or replace breather hose as

necessary, to prevent excess crankcase pressure

buildup.

Cooling Fan (49) - Visually check fan (49) for

cracks, loose rivets, and bent or loose blades. Check

fan mounting bolts (21) and tighten if required.

Replace fan (49) if damaged.

Note: The fan belt is maintained to the correct belt

tension by a spring loaded idler arm, therefore, there

is no need to check or adjust belt tension.

Alternator Drive Belt (2, Fig. 2) - Visually check

belt (2, Fig. 2) and replace if it is cracked or frayed.

Adjust belt if it has a glazed or shiny surface which

indicates belt slippage. A correctly installed and

tensioned belt will show even pulley and belt wear.

Check belt tension and adjust if necessary, as

described under 'Alternator Drive Belt'.

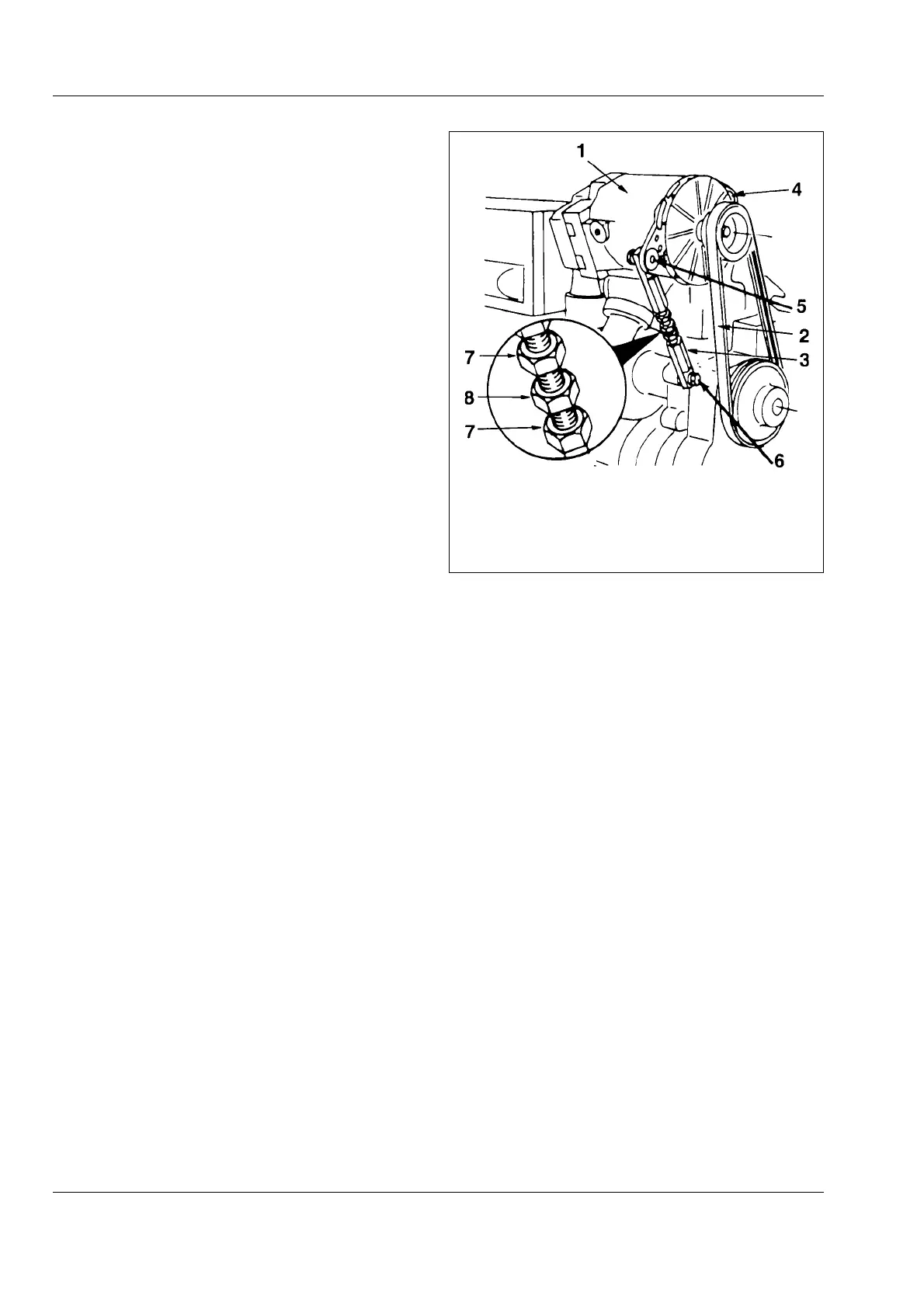

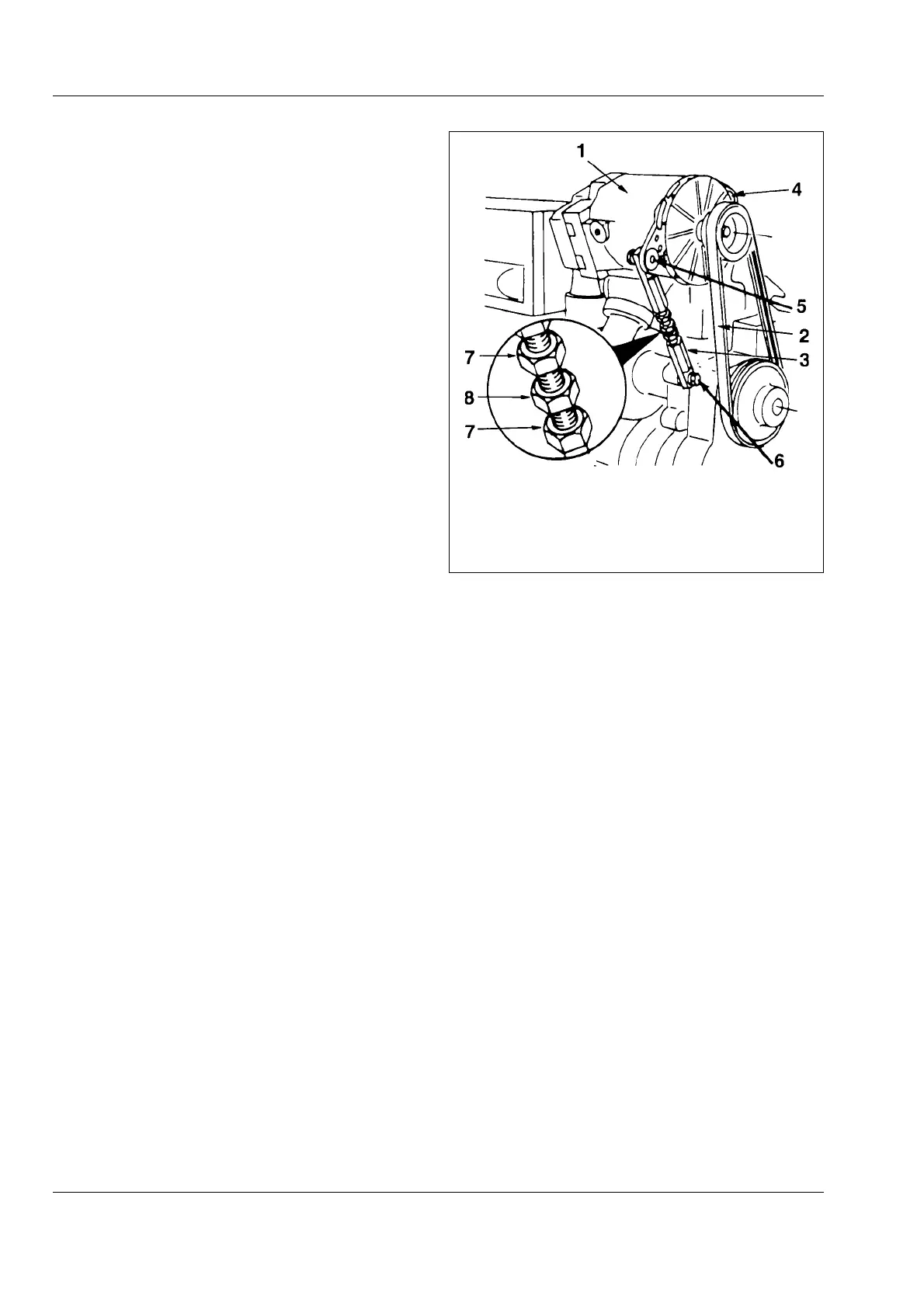

ALTERNATOR DRIVE BELT

Numbers in parentheses refer to Fig. 2.

Note: Position the vehicle in a level work area, apply

the parking brake and switch off the engine. Turn

steering wheel several times to relieve pressure in

the steering circuit. Block all road wheels.

SM - 1359

Belt Tension Check

Measure drive belt (2) tension in the centre span of

the drive pulleys using a belt tension gauge. The belt

tension should be within the following values:

Belt Tension 'New' - 670 N (150 lbf)

Belt Tension 'Used' - 270 - 530 N (60 - 120 lbf)

Note: A belt is considered 'Used' if it has been in

service for ten minutes or longer. If the used belt

tension is less than the minimum value, tighten the

belt to the maximum value.

Note: Tension specifications are based on a cold

belt. Hot shut down tension varies greatly depending

on engine speed, load and temperature, but is

approximately 30% higher.

An alternative method (deflection method) can be

used to check drive belt (2) tension by applying 110

N (25 lbf) force on drive belt (2) between the drive

pulleys. If the deflection is more than one belt

thickness per foot (305 mm) of pulley centre

distance, the belt tension must be adjusted.

Drive Belt Adjustment

Note: Lower jam nut (7) on adjusting screw (8) has

left hand threads.

Fig. 2 - Typical Alternator and Drive Belt Installation

1 - Alternator

2 - Drive Belt

3 - Adjusting Link

4 - Capscrew

5 - Capscrew

6 - Capscrew

7 - Jam Nut

8 - Adjusting Screw

Find manuals at http://best-manuals.com/search?&s=TEREX-SM1663.PDF

Loading...

Loading...