-9-

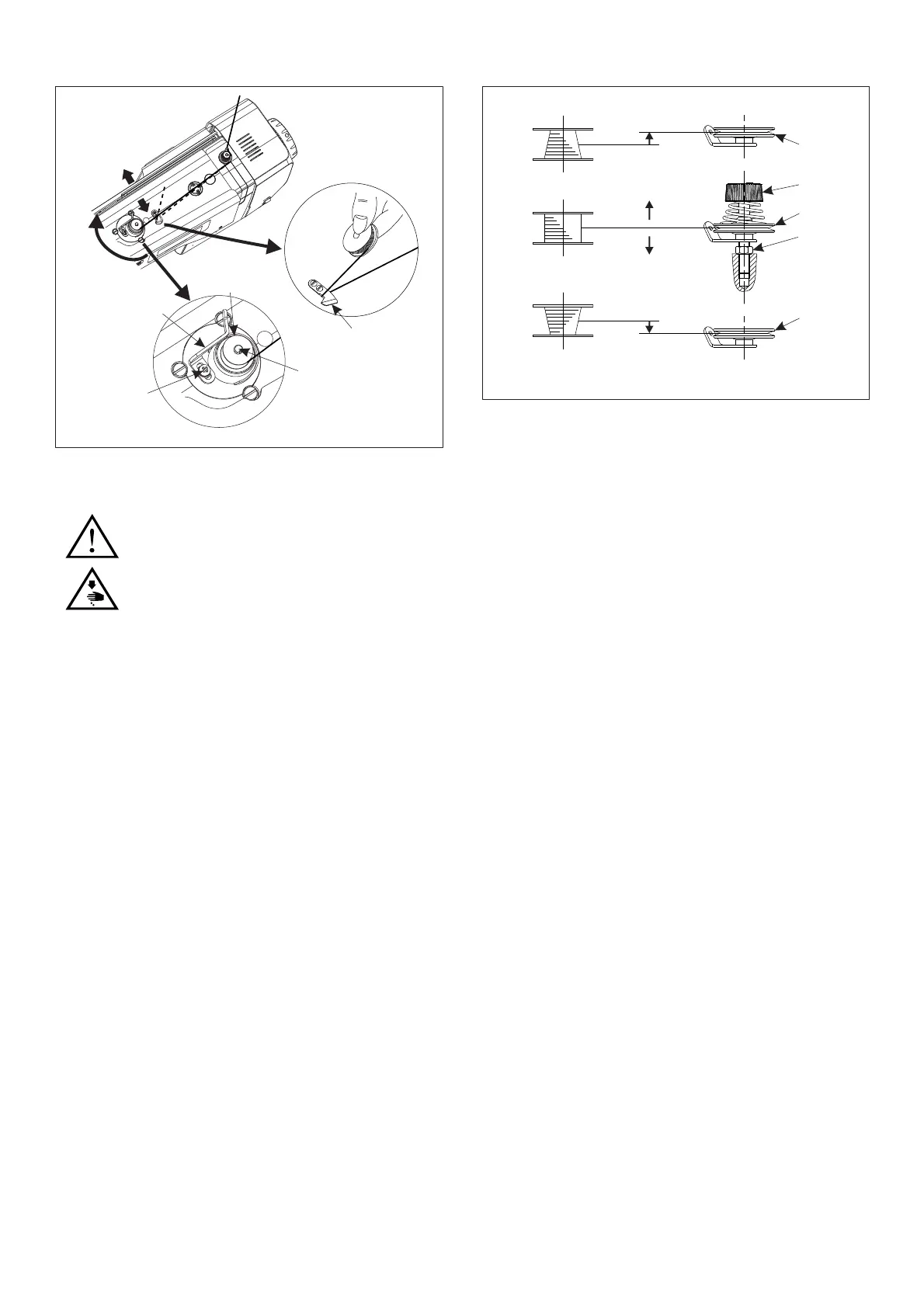

A

B

Fig.12

④

C

②

①

③

⑤

Fig.12

⑥

⑦

⑧

⑦

⑦

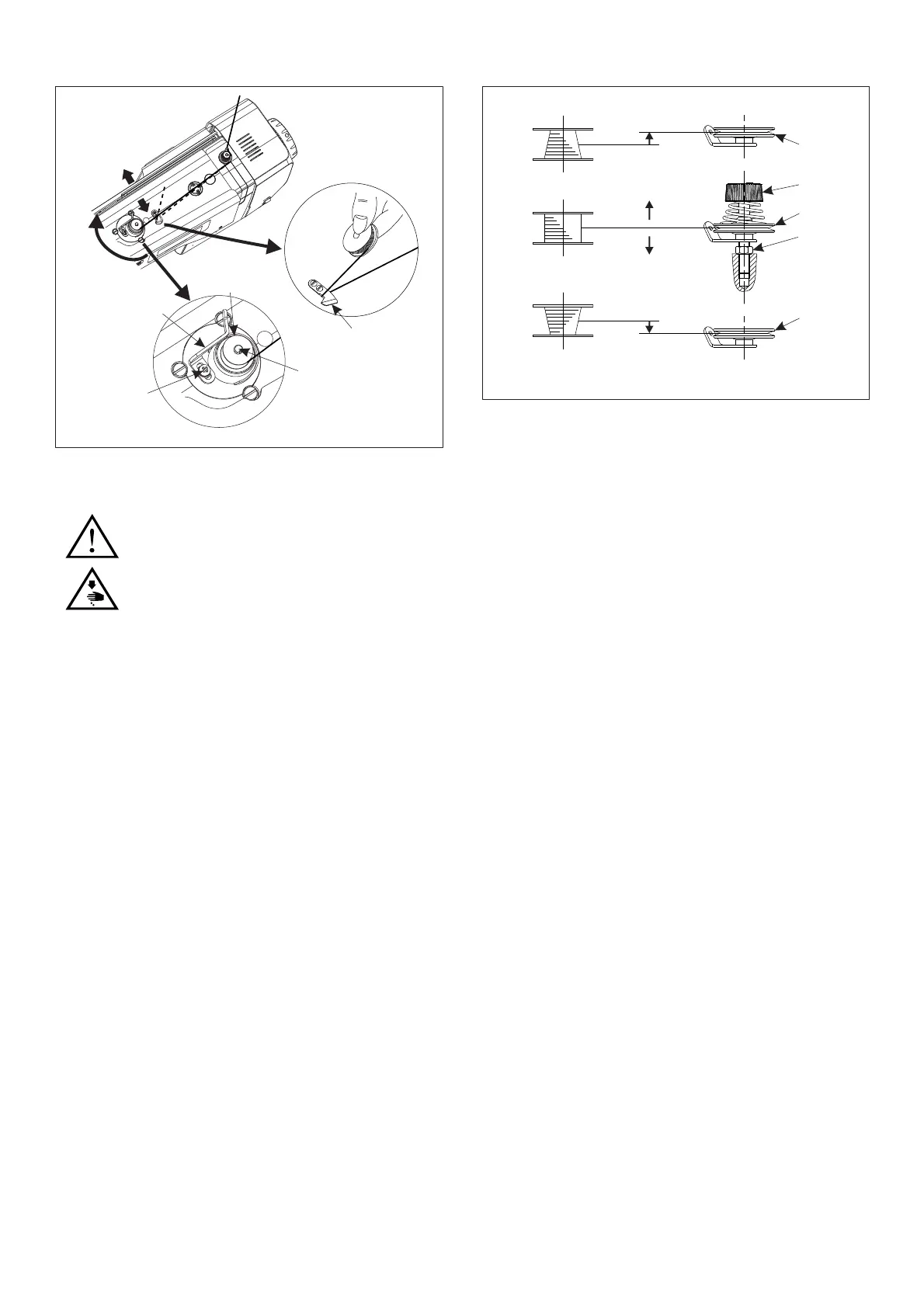

D

E

Caution:

1.To reel bobbin thread onto bobbin① when no sewing is performed, draw the needle

thread out of hole in the take-up lever, remove bobbin ① out of rotating hook.

2.Do not touch or lean anything to any running components when rolling the bottom

line,in order to avoid the safety accident.

1.Ad

justing the bobbin thread winding

1)To adjust the winding capacity of bobbinthread, unscrew fixing screw ⑤ ,set winding lever ③

in

direction A or direction B, and fix screw ⑤ again. Direction A is intended for reduction, and

direction B is intended for increase(CCaution:The amount of thread wound onto the bobbin

should be a maximum of 80% of the bobbin capacity).

2.If thread cannot be wound onto the bob

bin flatly, unscrew nut ⑥

, turn the winding tesion disco, and adjust the height of height of thread

gripper plate ⑦.

a. The standard position is reached once the center heights of rotating hook ①

and thread

gripper plate ⑦ are identical.

b. If the winding amount on the lower part is bigger, move the winding tension discoin direction

D indicated in the right hand figure.

3.If the winding amount on upper part is bigger, move the winding tension disco in direction E

indicated in the right-hand figure.

When the winding tension disco reaches its suitable position, screw down fixing screw ⑥

.

Adjust the winding tension of bobbin thread by turning thread tension nut ⑧. Thread the needle

thread when needle bar stays in its highest position, lead out the thread end from the thread

stand, and conduct threading as per the serial numbers indicated in the figure.

Loading...

Loading...