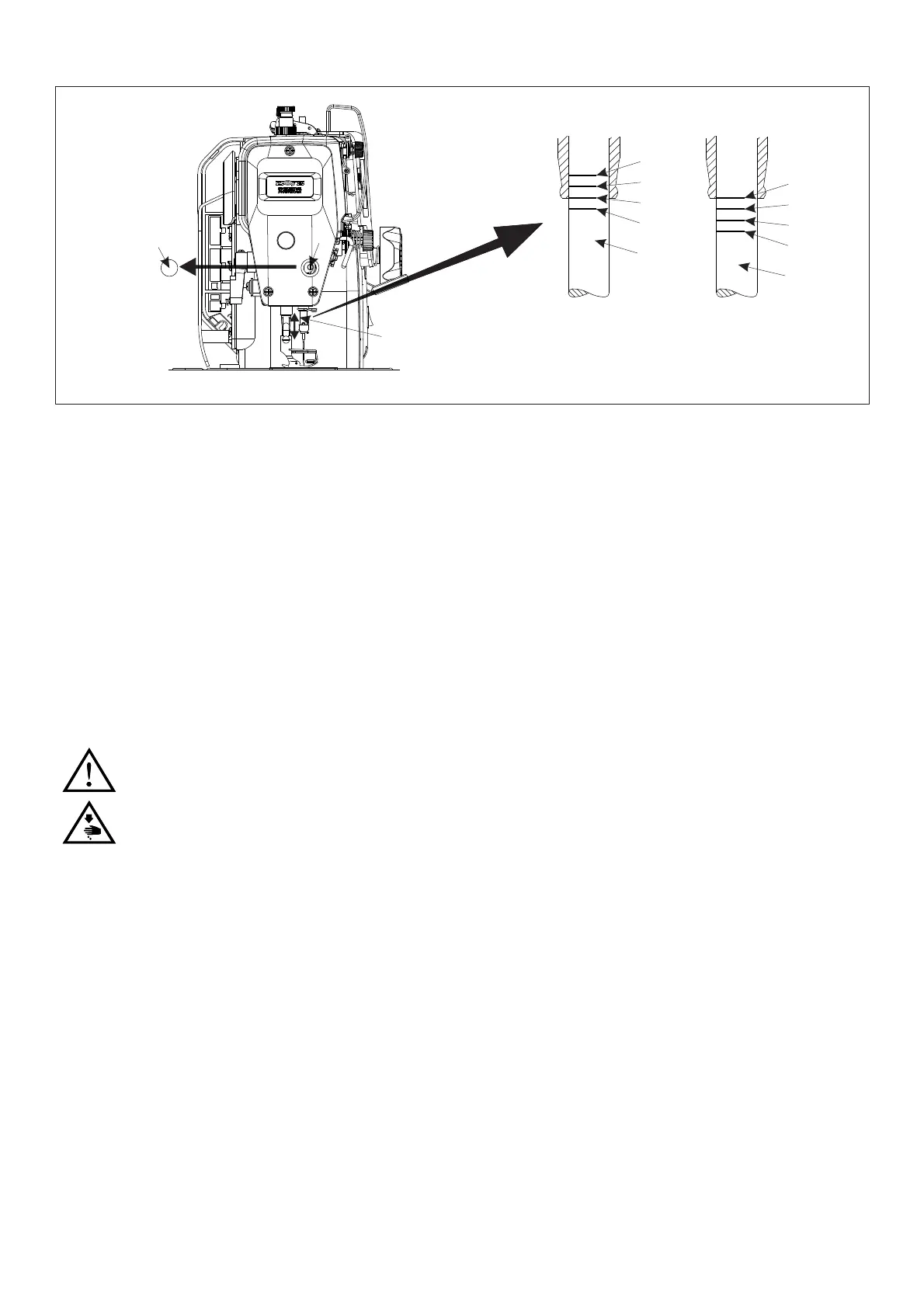

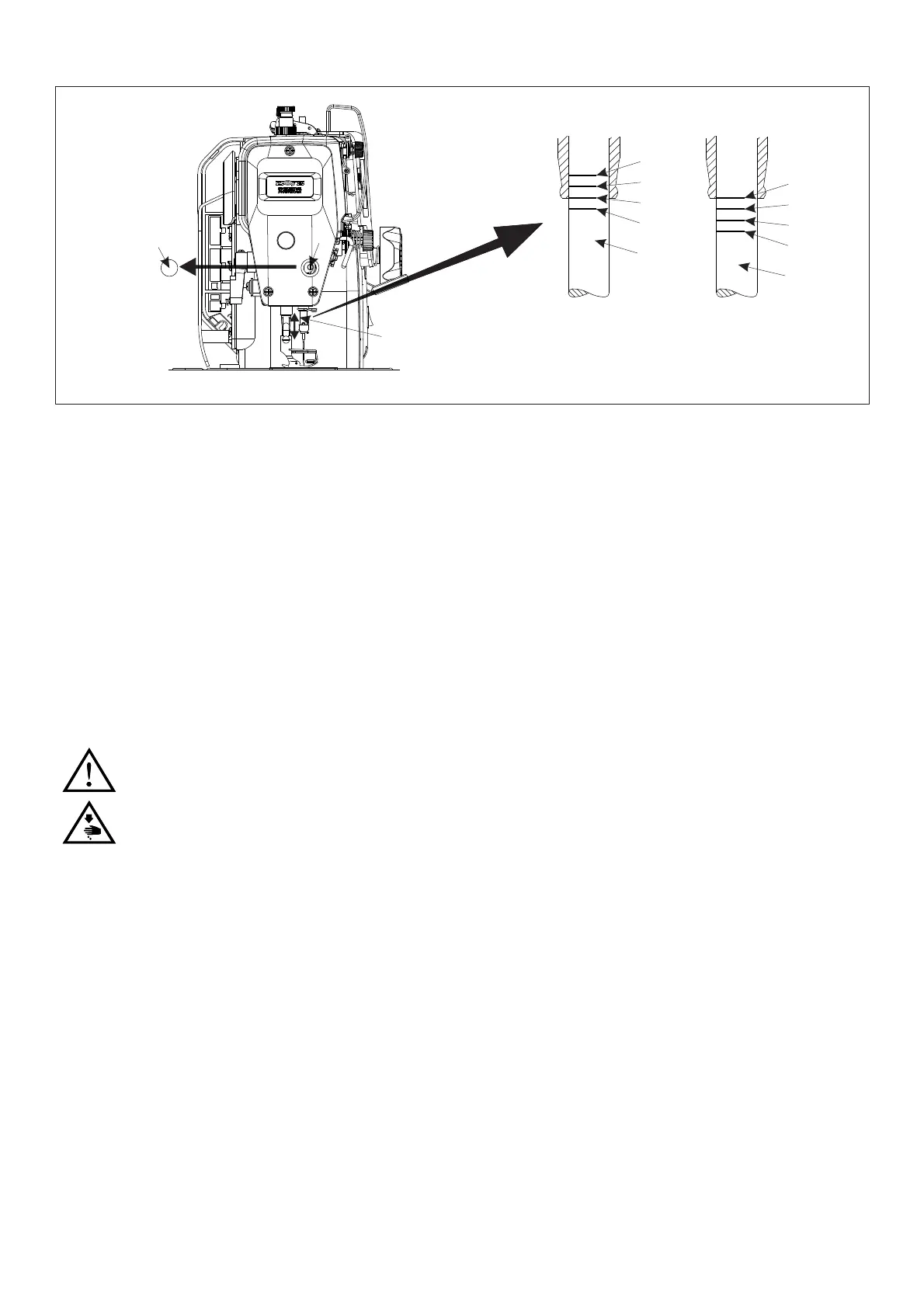

Fig.32

③

B

C

A

D

B

C

A

D

①

DB×1

DP×5

DA×1

①

①

②

25

Adjust t he Height of t he Needle B ar(Fig. 3 2)

1.Turn the machine pulley to set the needle bar ① to its lowest position.

2.Remove the rubber cap ② from the face plate.

3.Unscrewing the connecting screw

③ of needle bar, through moving the needle bar

① up and

down to adjust, when using needle DB X1 and DPX5, the mark A on the needle bar

①

should be

match to the bottom of needle bar lower bushing; When using DAX1, the mark C on needle bar

①

should match to the bottom of needle bar lower bushing.

4. Tighten the screw ③ in compression rod guide frame and assembly the rubber plug

② after

adjusting.

Caution:

1.To prevent the unexpected startup

of sewing machine, trim off the power

supply before the operation is conducted

26

Adjust the Synchronization of t

he needl

.

e and hook(Fig. 33)

1. Unscrewing the two positioning screw ①

of hook.

2. Rotating the hand wheel to make needle bar ②

lift from the lowest place, when using needle

DBX1 and DPX5, the mark B on needle bar② should match to the bottom of lower needle bar

② bushing, when using needle DAX1, the mark D on needle bar ② should match to the

bottom of lower needle bar ② bushing.

3. Moving the hook to match the hook point ③

with center of needle ④. Meantime, make the

space between the hook point ③ and needle ④ 0~0.05mm.

4. Tightening two positioning screw ①

of hook.

Loading...

Loading...