Caution:

1.To prevent the unexpected startup of sewing machine, trim off the power supply

before the operation is conducted.

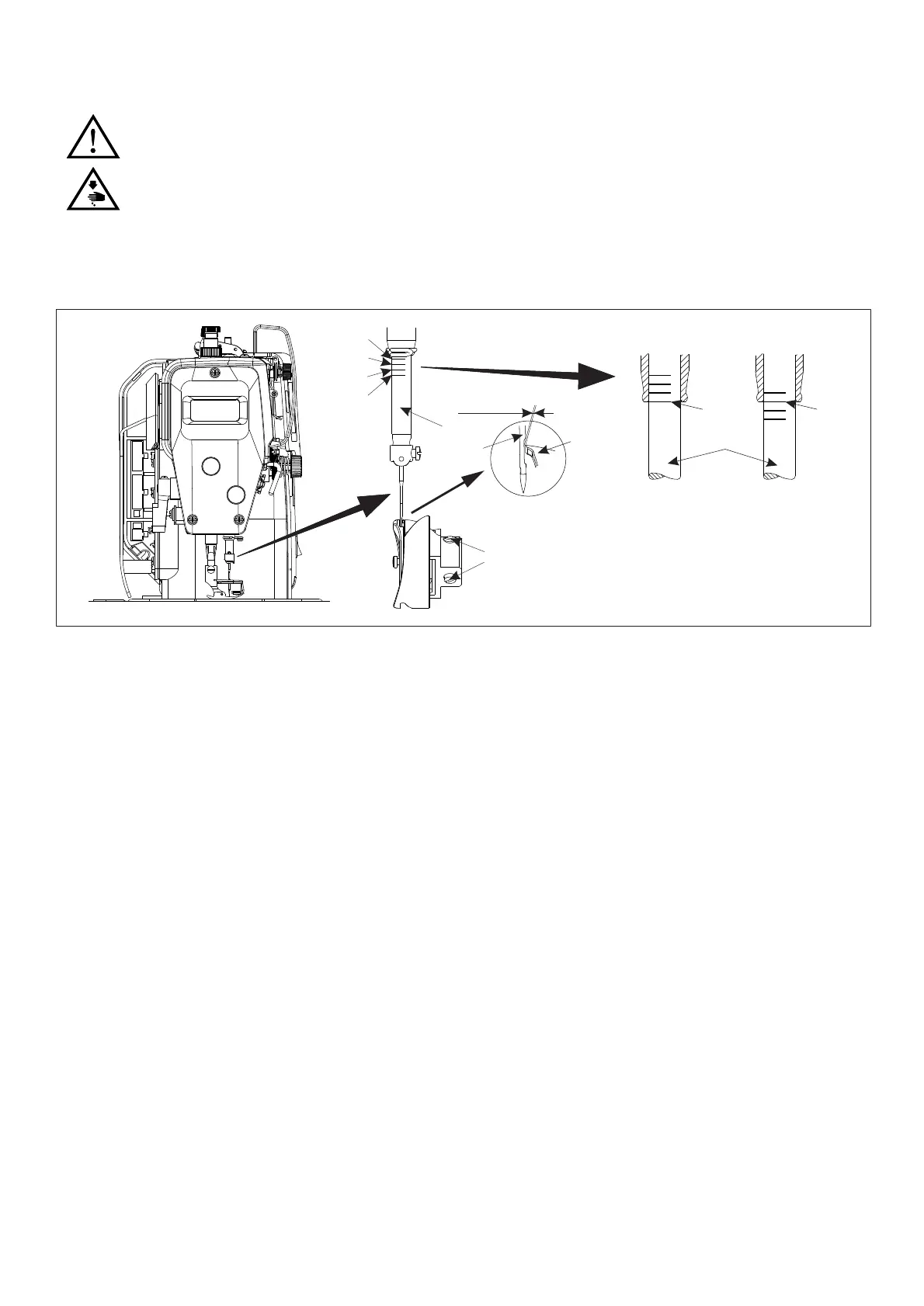

2.If the clearance between notch on needle and thread hooking tip of rot-

ating

hook is too small, rotating hook tip may be worn; if the clearance is

excessive, skipped stitch may take place.

3.It may lead to needle breakage if over-rotating the eccentric wheel towards A

direction.

Fig.33

B

C

A

D

②

0~0.05mm

④

③

DB×1

D

P×5

DA×1

B

D

②

①

27

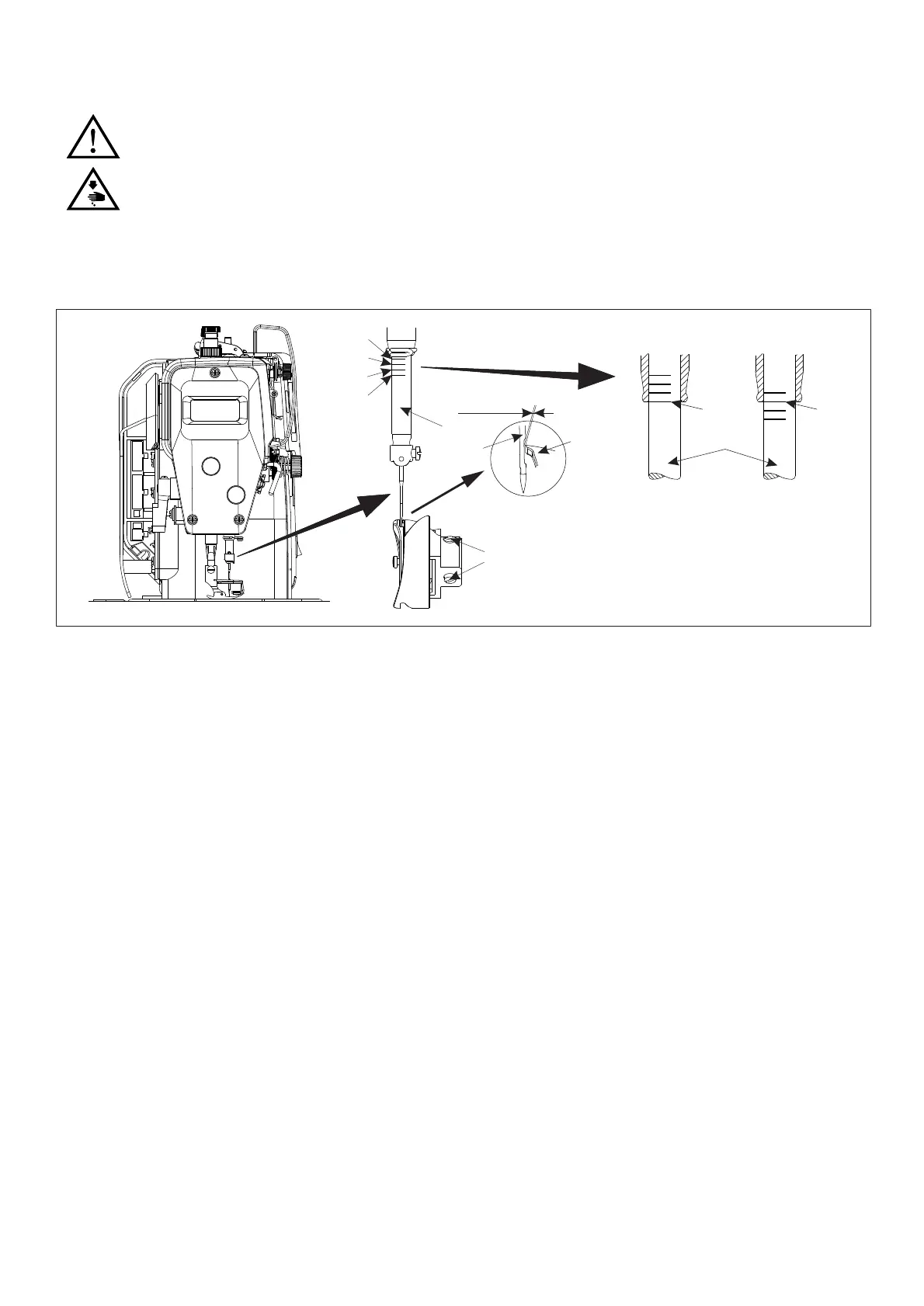

Adjust the Synchronization of the Needle and Feed(Fig. 34)

1.Remove the rubber plug ①.

2.Loosen the two set screws ③ of the feedeccentric cam ②,and then turn the feed eccentric cam ②

slightly to adjust the timing: If make the needle sooner than material feeding, rotate toward A

direction. If make the needle later than material feeding, rotate toward B direction. ( The standard

of adjustment is when the feed dog falling from the highest to the surface of needle plate, the top

of the needle and needle plate should at the same level).

3.Tightening two positioning screw

③ and assembly the rubber plug

① after adjusting.

Loading...

Loading...