Caution:

1.To prevent the unexpected startup of sewing machine, trim off the power supply

before the operation is conducted.

2.If the feed lifting eccentric cam is turned too far in the direction A, it may cause

the needle to break.

3.To prevent material slippage from occurring,retard the needle timing.

4.To improve thread tightening, adv ance the needle timing.

28

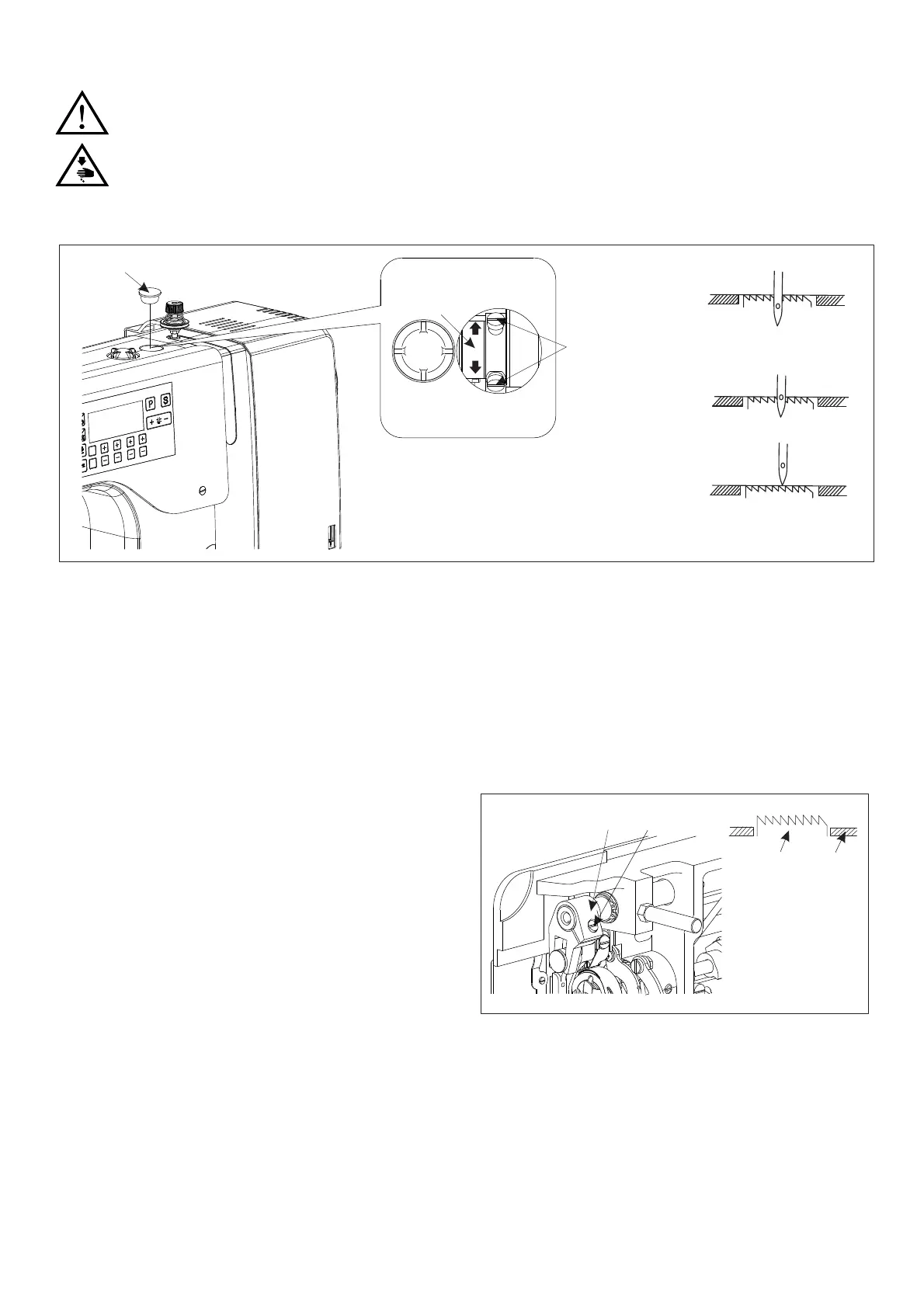

Adjustment of t he Height of f eed d og(Fig. 3 5)

Fig.34

A

②

①

B

Standard

Needle timing

is retarded

Needle timing

is advanced

③

1.Turn the pulley until the feed dog rises to the

highest position.

2.Turn over the sewing machine head on the

supporting bar.

3. Unscrewing the tightened screw ① in the

feed lifting crank

②.

4.Rotating the feed lifting crank

② to make

adjustment:

the feed dog will be higher when the feed lifting

crank ② is turn towards A direction;

turn towards B direction the feed dog will be

lower.(When the feed dog in the highest position,

the standard height of the type of medium-heavy

machine is 0.8~1.0mm and standard height of the

heavy duty machine is 1.1~1.3mm.

5.Remember to tighten the tightening screw

①

in

the feed lifting crank

② after adjusting.

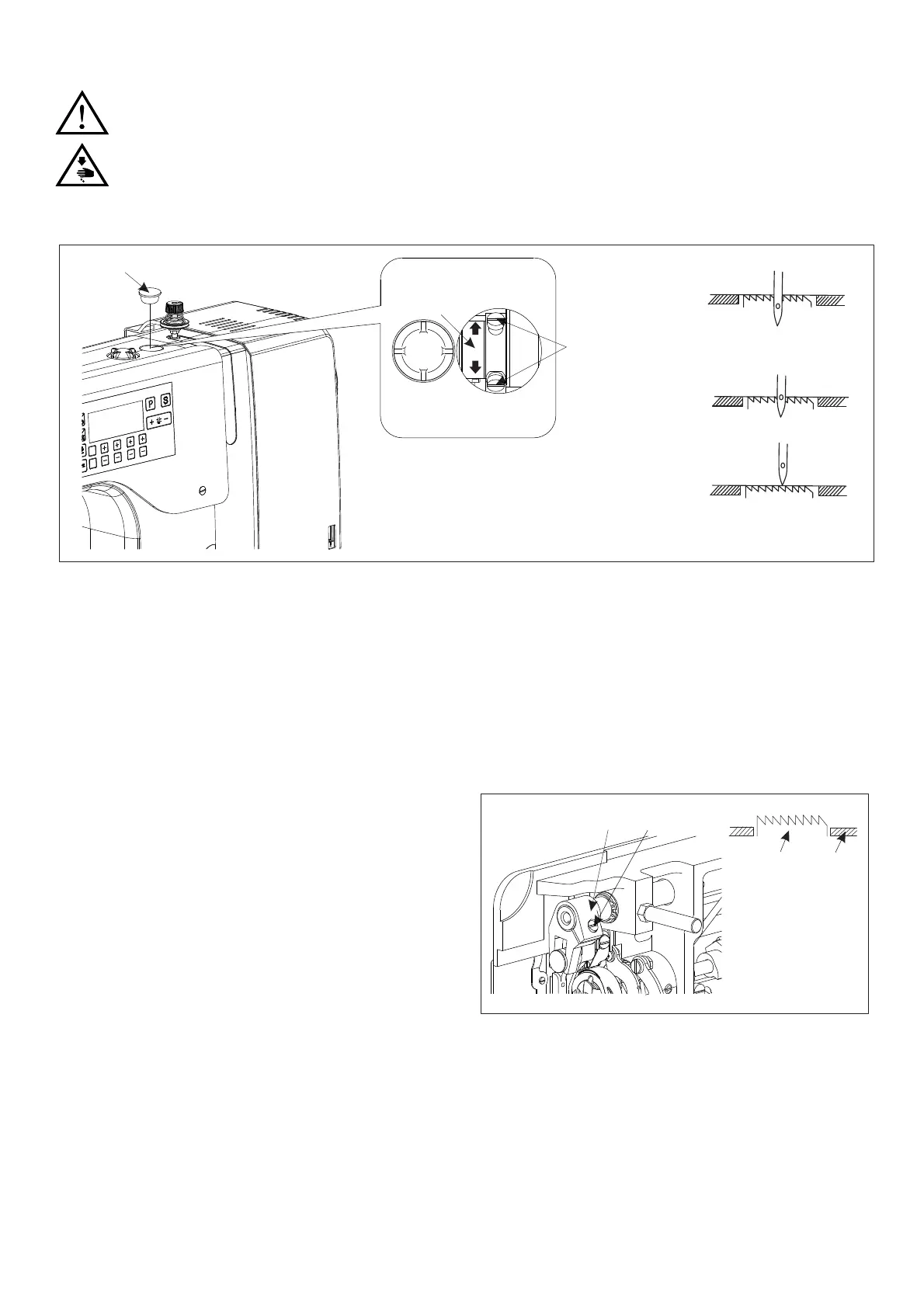

Fig.35

①

②

A B

A:Feed dog

B:Needle plate

Loading...

Loading...