Do you have a question about the Thermo Scientific 1375 and is the answer not in the manual?

Details negative pressure, personnel, and product protection features.

Explains the function of HEPA filters in downflow and exhaust airflow.

Overview of the display, keys, and status indicators on the control panel.

Describes window positions for access, operation, and energy saving.

Details accessory outlets, service ports, RS-232, and remote alarm connections.

Information on the bright workspace lighting and bulb configuration.

Explains the optional UV light installation, operation, and safety.

Details the work tray, armrest placement, and working area dimensions.

Part numbers and installation guide for the optional exhaust connection.

Instructions for installing exhaust system components on 3, 4, 5, and 6 ft models.

Precautions and procedures for safely transporting and lifting the cabinet.

Step-by-step guide for installing service valves into side panels.

Details on factory-installed piping options and available access points.

Description of the optional SmartPort for organizing tubing and cables.

Procedure and location for installing the drain valve.

Comprehensive instructions for assembling the cabinet stand.

Procedure to unlock the window counterweight for safe operation.

Steps for ensuring the cabinet is perfectly level for optimal performance.

Guidelines for safe electrical connection and power supply.

Mandatory tests required for safe operation and certification.

Information on industry organizations for cabinet certification.

Explanation of the display, keys, and status indicators for operation.

Steps to turn on the unit and confirm readiness for operation.

Details on OFF, Working, UV, Window open, and Standby modes.

Procedure for safely loading samples into the work chamber.

Information on error codes and initial troubleshooting steps.

Best practices and safety guidelines for operating the cabinet.

Guidance on proper posture, chair, and footrest for user comfort.

Steps for normal, extended, and disposal shut-down of the unit.

Properties and proper cleaning methods for stainless steel surfaces.

Maintenance guidelines for powder-coated surfaces.

Steps for general disinfection, rinsing, and UV disinfection.

Procedures for thorough decontamination using various methods.

Instructions for cleaning exterior surfaces, window, and drain pan.

Procedure for removing and installing the paper catch grid.

Requirements for annual certification and recommended inspection points.

Guidance on filter replacement and sample chamber light bulb changes.

Procedures for replacing UV lights and other components.

Guidelines for the safe disposal of the cabinet and its components.

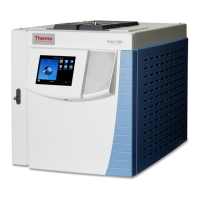

Detailed dimensions and model number specifications for the cabinet.

Specifications for drain pan volume, cabinet/stand weights, and load limits.

Operating temperature, humidity, and noise level specifications.

Technical specifications including voltage, current, power, and protection.

Details on airflow velocities, volumes, and filter specifications.

Cabinet classification and definitions of key testing terminology.

Summary of mandatory and optional certification tests.

Listing of recommended equipment for various certification tests.

Procedures for DIM, Constricted Window, and Exhaust Calculation methods.

Methods and calculations for measuring downflow velocity.

Procedure to determine the integrity of HEPA filters.

Methods for evaluating airflow behavior using smoke.

Tests for electrical safety, facility integration, and airflow alarms.

Verification of window alarms and exhaust system functionality.

Template for recording service, maintenance, and operator notes.

Details of warranty coverage for USA and international customers.

| Type | Class II, Type A2 |

|---|---|

| Noise Level | ≤65 dBA |

| UV Light | Optional |

| Category | Biological Safety Cabinet |

| Class | Class II |