Do you have a question about the Thermo Scientific 1300 Series and is the answer not in the manual?

Defines the proper and improper applications of the biological safety cabinet.

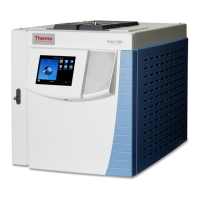

Identifies and illustrates the main parts of the biological safety cabinet.

Explains airflow, protection features, HEPA filters, and safety lockout features.

Details the functions and indicators of the main control interface.

Describes how to operate the front window for various functions and positions.

Covers accessory outlets, ports, RS-232, and remote alarm connections.

Explains the internal lighting and optional UV disinfection system.

Describes the workspace, including the work tray and armrest placement.

Outlines the necessary ambient conditions and space requirements for safe installation.

Details the installation of optional exhaust transitions and accessories.

Provides instructions on how to safely move and transport the safety cabinet.

Explains how to install service valves and replace SmartPort grommets.

Describes the factory-installed universal piping option.

Step-by-step guide for assembling the optional stand for the cabinet.

Procedures for unlocking the window counterweight and ensuring the cabinet is level.

Instructions for safely connecting the unit to the power source.

Details the required tests before initial operation to ensure safety and performance.

Explains the display, keys, and status indicators on the control panel.

Step-by-step guide for powering on and preparing the unit for operation.

Describes the different modes of operation (OFF, Working, Standby, UV).

Guidelines for safely placing samples and performing work within the chamber.

Provides advice for safe operation and proper working practices.

Information on interpreting error codes and procedures for shutting down the unit.

Instructions for cleaning stainless steel surfaces, preventing corrosion.

Outlines methods for cleaning, rinsing, UV, and formaldehyde disinfection with timing adjustments.

Details cleaning procedures for exterior surfaces, windows, drain pans, and paper catch grids.

Guidelines for regular checks and the annual certification process.

Instructions for servicing, replacing sample chamber lights and optional UV lights.

Information on handling repairs and unit disposal procedures.

Provides physical dimensions, weights, and load capacities for different models.

Lists operating temperature, humidity, heat dissipation, and noise level specifications.

Details electrical specifications, including voltage, current, fusing, and protection types.

Outlines airflow velocities, volumes, filter types, and dimensional data.

Defines cabinet classification and key terms used in testing.

Lists required tests for personnel, product, and environmental safety.

Recommends testing equipment and provides details on specific tests like inflow velocity.

Explains procedures for testing HEPA filter integrity and airflow patterns using smoke.

Details verification of airflow, sash, and exhaust system alarms and performance.

| Type | Biological Safety Cabinet |

|---|---|

| Class | Class II |

| Filter | HEPA |

| Material | Stainless steel |

| Temperature Uniformity | N/A (Biological Safety Cabinet, not an incubator) |

| Display | Digital |

| Timer | Yes |

| Power Requirements | 115 V, 60 Hz or 230 V, 50 Hz |

| Noise Level | ≤65 dB |

| Temperature Range | N/A (Biological Safety Cabinet, not an incubator) |