Do you have a question about the Thermo Scientific 1384 and is the answer not in the manual?

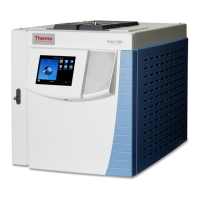

Detailed description of the cabinet's physical parts and features.

Information on negative pressure, personnel, and product protection mechanisms.

Explanation of HEPA filter functionality and airflow verification methods.

Guide to using the control panel and operating the front window.

Details on external ports, internal outlets, chamber lighting, and UV lights.

Description of the workspace, armrests, and UV light operation.

Necessary ambient conditions, location, and ventilation for installation.

Instructions for installing optional exhaust transitions and accessories.

Procedures for safely moving the cabinet and identifying lift points.

Steps for connecting utilities and data cables via ports.

Description of factory-installed piping options for utilities.

Specific steps for installing the drain valve for liquid removal.

Steps for assembling the stand and securely mounting the cabinet.

Essential pre-operation safety and alignment steps.

Procedures for connecting power and mandatory installation tests.

Information on finding qualified third-party certifiers for the cabinet.

Explanation of control panel functions and how to start the unit.

Understanding different operational states and sample loading.

Guidance on troubleshooting errors and best practices for safe operation.

Procedures for turning off, extended storage, and decommissioning the unit.

Procedures for cleaning different material surfaces of the cabinet.

General methods for cleaning, disinfecting, and rinsing the cabinet.

Detailed sterilization procedures for the entire cabinet.

Instructions for cleaning exterior surfaces, the front window, and the drain pan.

Procedure for removing and cleaning the paper catch grid.

Required certification checks and recommended regular inspections.

Guidance on general service, replacing light bulbs, and other repairs.

Procedures for decommissioning and discarding the unit according to regulations.

Physical dimensions, weights, loads, and model variations.

Ambient conditions, temperature, humidity, and user comfort factors.

Electrical specifications and airflow volumes/velocities.

Defining cabinet classification (NSF/ANSI 49) and key testing terms.

Overview of required on-site certification tests and recommended equipment.

Specific procedures for HEPA filter leak tests and airflow pattern analysis.

Other critical certification tests, including electrical safety and alarm functions.

Table for recording maintenance, service history, and technician notes.

Details on warranty coverage, duration, and contact information.

| Temperature Uniformity | ±0.3°C at 37°C |

|---|---|

| Humidity Range | 95% RH |

| CO2 Range | 0 to 20% |

| CO2 Accuracy | ±0.1% |

| Type | CO2 Incubator |