Do you have a question about the Thermo Scientific 1385 and is the answer not in the manual?

Describes negative pressure, personnel and product protection mechanisms.

Explains the downflow and exhaust HEPA filter system for air cleaning.

Details the function and placement of grids to prevent debris entry.

Overview of display, keys, and status indicators for cabinet operation.

Explains different window positions for access, cleaning, and energy saving.

Details accessory outlets, service ports, RS-232, and remote alarm connections.

Describes the fluorescent lighting system for workspace illumination.

Explains the optional UV light for disinfection and its safety interlocks.

Details the workspace, armrest placement, and safety considerations.

Instructions for installing the optional thimble exhaust connection.

Proper procedures and precautions for safely moving the biological safety cabinet.

Steps for installing service valves through side panel access ports.

Procedure for replacing SmartPort grommets prior to decontamination.

Details factory-installed piping options and access points.

Explains the SmartPort feature for routing cables and tubing.

Instructions for installing the drain valve after unit setup.

Guides for assembling the unit's stand and attaching the cabinet.

Procedure for releasing the window counterweight secured for shipping.

Instructions for ensuring the cabinet is perfectly level for optimal function.

Steps for safely connecting the unit to the power source.

Overview of required NSF/ANSI 49 certification and installation tests.

Information on organizations for finding accredited certification services.

Step-by-step guide to powering on and preparing the cabinet.

Explains different operational states like OFF, Working, Standby, and UV modes.

Procedures for safely loading samples into the work chamber.

Information on displayed error codes and initial troubleshooting steps.

Guidelines for safe operation, including PPE and environmental factors.

Procedures for safely turning off and preparing the unit for non-use.

Steps for decontaminating and shutting down the unit for long-term storage.

Guidelines for proper disposal of the cabinet and its components.

Proper methods for cleaning and maintaining stainless steel surfaces.

Guidelines for cleaning and maintaining powder-coated surfaces.

General procedures for disinfecting the cabinet and its components.

Steps for rinsing surfaces with distilled water after cleaning.

How to use the UV light for disinfection after cleaning.

How to adjust the preset UV disinfection timer.

Procedures for comprehensive space decontamination using specific agents.

Instructions for cleaning the exterior surfaces of the cabinet.

Method for cleaning the front window, allowing access below the closing position.

Steps for thoroughly cleaning the drain pan and its components.

How to remove, clean, and reinstall paper catch grids.

Overview of annual certification checks and recommended inspection points.

Information on filter replacement and general service requirements.

How to replace fluorescent bulbs in the sample chamber.

Procedure for replacing the optional UV light bulb.

Notes on retrofitting systems and general repair considerations.

Guidelines for proper disposal of the cabinet and filters.

Details the unit's classification as Class II, Type A2 per NSF/ANSI 49.

Definitions of key terms used in certification testing, like FPM and CFM.

Lists the required NSF/ANSI 49 tests and optional comfort/safety tests.

Recommended equipment for conducting certification tests.

Detailed method, calculations, and acceptance for Inflow Velocity (DIM).

Detailed method, calculations, and acceptance for Inflow Velocity (Constricted Window).

Detailed method, calculations, and acceptance for Inflow Velocity (Exhaust Flow).

Detailed method, calculations, and acceptance for Downflow Velocity.

Procedure for testing the integrity of HEPA filters for leaks.

Method and acceptance criteria for scanning accessible filters.

Method and acceptance criteria for filters not directly accessible.

Procedures for evaluating airflow patterns using smoke.

Tests verifying electrical safety and grounding.

Procedure to verify proper integration of the unit into the facility.

How to test the activation of downflow and inflow airflow alarms.

Verifying the proper operation of the window (sash) alarm.

Checking the proper functioning of the exhaust system and canopy.

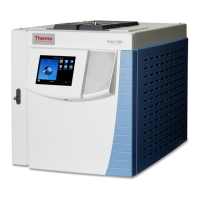

| Brand | Thermo Scientific |

|---|---|

| Model | 1385 |

| Category | Laboratory Equipment |

| Language | English |