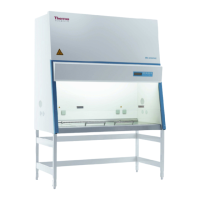

How to troubleshoot a Thermo Scientific MaxQ 4000 shaker that doesn’t operate?

- JJesse BurkeAug 4, 2025

If your Thermo Scientific Laboratory Equipment shaker isn't operating, there are several potential causes: * Ensure the power cord is properly plugged in. * Verify the power supply matches the requirements listed on the data label. * For E-Class models: * Check and reset the circuit breaker. * Look for flashing lights on the control panel and press any switch. * See if the elapsed timer is flashing and reset it. * For A-Class models: * Confirm the timer isn't in the off position and set it for continuous or timed operation. * Check the power switch and replace it if it's defective.