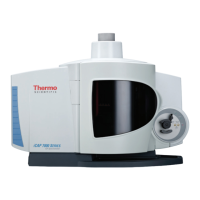

Do you have a question about the ThermoFisher Scientific iCAP 7000 Plus Series and is the answer not in the manual?

| Brand | ThermoFisher Scientific |

|---|---|

| Model | iCAP 7000 Plus Series |

| Category | Laboratory Equipment |

| Language | English |

Information regarding legal notices and copyright.

Introduction to the manual's content and purpose.

Explains formatting conventions used in the manual.

Defines safety signal words like CAUTION, WARNING, DANGER.

Defines terms like 'left' and 'right' from the operator's perspective.

Describes conventions for data input and computer interaction.

Explains the structure of headings within chapters.

Lists other relevant documents for the ICP-OES system.

Provides contact information for Thermo Fisher Scientific.

Details how to get help and support for the instrument.

Provides information on how to submit feedback or suggest changes.

Lists mandatory accessories for the ICP-OES system.

Lists optional accessories that can enhance system functionality.

Provides an overview of the ICP-OES system and its components.

Details the technical specifications of different iCAP models.

Describes the echelle optical design and its components.

Details the specifications of the CID detector.

Explains the Random Access Integration (RAI) detector mode.

Describes the dedicated radial and duo view plasma configurations.

Details the RF generator and plasma source specifications.

Covers nebulizer, spray chamber, sample pump, and torch details.

Lists different center tube options for the torch.

Discusses various nebulizer options available for the system.

Describes the requirements and considerations for peristaltic pump tubing.

Explains the use and function of the Internal Standards Kit.

Discusses specific considerations for analyzing organic solvents.

Details sample introduction for light organic samples.

Details sample introduction for heavy organic samples.

Discusses controlling sample loading for volatile organic samples.

Addresses challenges and accessories for samples with high dissolved solids.

Explains the function of the Argon Humidifier accessory.

Describes the Aerosalt Nebulizer for high dissolved solids.

Details the Parallel Path Nebulizer for high dissolved solids.

Explains the use of the Sheath Gas Adaptor for analytical stability.

Discusses specific components and procedures for analyzing HF samples.

Explains safety symbols, signal words, and general guidelines.

Emphasizes reading and understanding safety information before operation.

Describes warning labels found on the instrument itself.

Explains the importance of the instrument's rating plate for identification.

Defines the proper usage guidelines and limitations of the ICP-OES system.

Identifies the primary audience and required knowledge for using the manual.

Lists materials and gases compatible with the ICP-OES system.

Details critical safety measures related to high voltage and electrical hazards.

Addresses actions to take when safety features are compromised.

Provides procedures for safely shutting down the system in an emergency.

Warns about potential hazards like toxic gases, suffocation, and hot surfaces.

Recommends appropriate PPE for handling hazardous materials.

Outlines essential safety precautions during system installation.

Provides physical dimensions and weight of the ICP-OES spectrometer.

Details the environmental and resource prerequisites for installation.

Lists preparatory steps and considerations before beginning the installation.

Specifies ideal placement and space requirements for the instrument.

Defines acceptable temperature, humidity, and pressure for operation.

Details the necessary electrical supply specifications and connections.

Specifies the type, purity, and pressure of gases required for operation.

Describes the requirements and specifications for the cooling system.

Discusses proper procedures and containers for waste disposal.

Emphasizes the critical need for and setup of fume extraction.

Addresses additional extraction needs for volatile or acidic samples.

Explains the Ethernet connection for data station communication.

Details firewall and IP address settings for instrument communication.

Lists the hardware and software specifications for the data station PC.

Provides a summary of site requirements for installation.

Lists safety precautions to follow during instrument operation.

Describes initial steps to power up and prepare the ICP-OES for operation.

Explains the meaning of various LED indicators on the instrument.

Discusses the importance and process of optimizing instrument performance.

Details parameters affecting data and the need for method-specific optimization.

Explains how to adjust pump tension for optimal operation and tubing life.

Guides the assembly and installation of glassware for sample introduction.

Provides instructions for assembling and installing the Duo Torch.

Provides instructions for assembling and installing the Radial Torch.

Details how to connect pump tubing for sample introduction.

Explains the radial view interfaces for Duo instruments.

Describes the cleaning procedure for the radial glass window.

Details the Radial POP interface and its alignment procedure.

Provides a sample procedure for setting up and running analyses.

Outlines steps for preparing the system before starting operations.

Describes the procedure for igniting the plasma and checking interlocks.

Guides users through creating LabBooks and setting up analytical methods.

Details how to schedule and run analyses using the Qtegra software.

Explains how to generate and customize reports for acquired data.

Describes how to export LabBooks and other data files.

Explains the Auto Peak Adjust procedure for wavelength accuracy.

Provides step-by-step instructions for safely shutting down the instrument.

Lists safety precautions to observe during troubleshooting activities.

Addresses common issues related to starting and maintaining plasma ignition.

Describes checks for the ignition spark mechanism.

Explains how to check RF power delivery to the induction coil.

Discusses potential causes for the plasma extinguishing during operation.

Addresses issues with plasma going out and resolving analytical result problems.

Provides steps to verify the sample introduction system's condition.

Addresses specific issues like poor precision, accuracy, and detection limits.

Discusses causes and solutions for inconsistent analytical results.

Details how to resolve issues related to inaccurate or delayed feedback.

Explains how to improve detection limits, often related to precision issues.

Offers maintenance steps to address precision and detection limit problems.

Guides on selecting and replacing pump tubing for optimal performance.

Provides suggestions to prevent nebulizer tip blockage.

Describes procedures for cleaning solids from the nebulizer.

Lists safety precautions to follow when performing maintenance tasks.

Provides general guidelines for cleaning the instrument and accessories.

Details procedures for cleaning sample introduction components.

Explains methods for cleaning the torch, including carbon deposit removal.

Describes procedures for cleaning the spray chamber.

Provides instructions for cleaning the nebulizer.

Details the process for cleaning the POP window.

Explains how to clean radial view interfaces on Duo instruments.

Covers periodic checks for maintaining optimal performance.

Highlights critical maintenance aspects of the water chiller.

Advises on checking and maintaining the water filter.

Advises on checking and maintaining gas filters.

Guides on performing torch alignment for optimal results.

Outlines services provided by Thermo Fisher Scientific and safety advice for returns.

Provides safety recommendations for returning contaminated parts.

Gives instructions and precautions for returning parts for exchange or repair.

Specifies maintenance tasks exclusively handled by service engineers.

Describes the Sprint Valve rapid sample introduction system.

Lists autosamplers compatible with the Sprint Valve system.

Details the construction and material properties of the Sprint Valve.

Guides on establishing plumbing connections for the Sprint Valve.

Provides specific instructions for connecting tubing to the Sprint Valve.

Explains how to configure the Sprint Valve using the Qtegra plugin.

Details the timing parameters for Sprint Valve operation.

Describes manual control options for the Sprint Valve.

Explains how to access manual control features via the external configurator.

Explains how to configure the Sprint Valve using the Qtegra plugin.

Guides on performing manual sampling with the Sprint Valve.

Outlines daily and weekly maintenance tasks for the Sprint Valve system.

Advises on visually inspecting Sprint Valve system components.

Details procedures for checking and replacing tubing for leaks.

Emphasizes the importance of cleaning the Sprint Valve system.

Provides guidance for daily external cleaning of the Sprint Valve.

Details the periodic disassembly and cleaning of the 6/7-port valve.

Explains the procedure for re-homing the valve after removal.

Guides on replacing or reorienting the valve.

Provides instructions for installing the additional gas accessory.

Describes the autosampler and its configuration for ICP-OES.

Guides on setting up the autosampler tubing connection.

Details the use and setup of the ultrasonic nebulizer for increased sensitivity.

Provides instructions for connecting and setting up the ultrasonic nebulizer.

Explains hydride generation techniques for enhanced detection capabilities.

Describes the on-line hydride generation kit and its components.

Outlines setup procedures for hydride generation accessories.

Explains the function and assembly of the Gas Liquid Separator.

Provides instructions for preparing the Gas Liquid Separator before use.

Details the color-coded pump tubing for the GLS unit.

Covers WEEE compliance, RoHS, and the Declaration of Conformity.

Provides the Health and Safety Declaration form for material returns.

Defines technical terms, acronyms, and abbreviations used in the manual.

Provides an alphabetical index for quick reference to topics and page numbers.