12

SUPER CUTSUPER CUT

SUPER CUTSUPER CUT

SUPER CUT

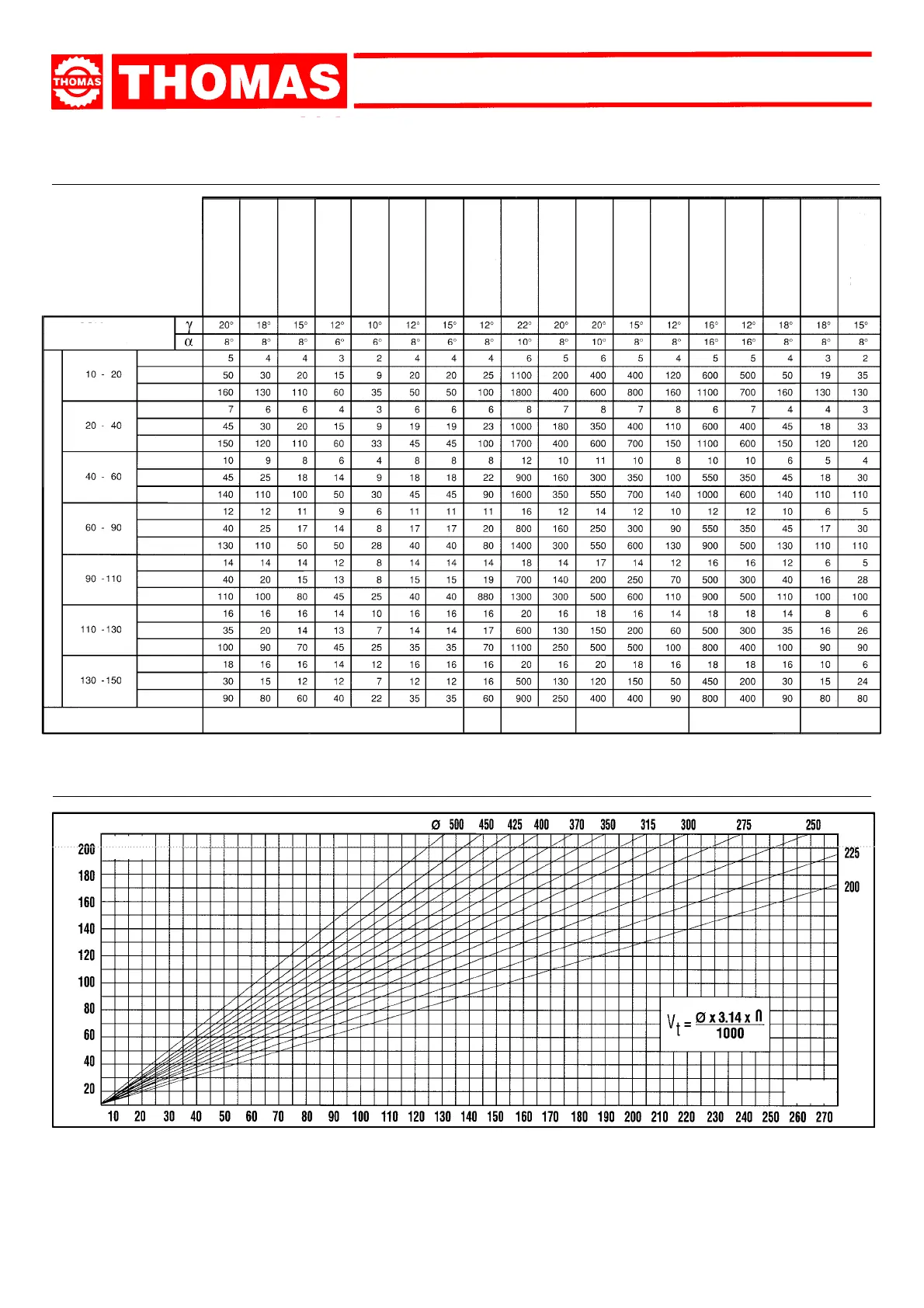

9.7.2 - DIAGRAM OF CUTTING SPEEDS ACCORDING TO DISK DIAMETER

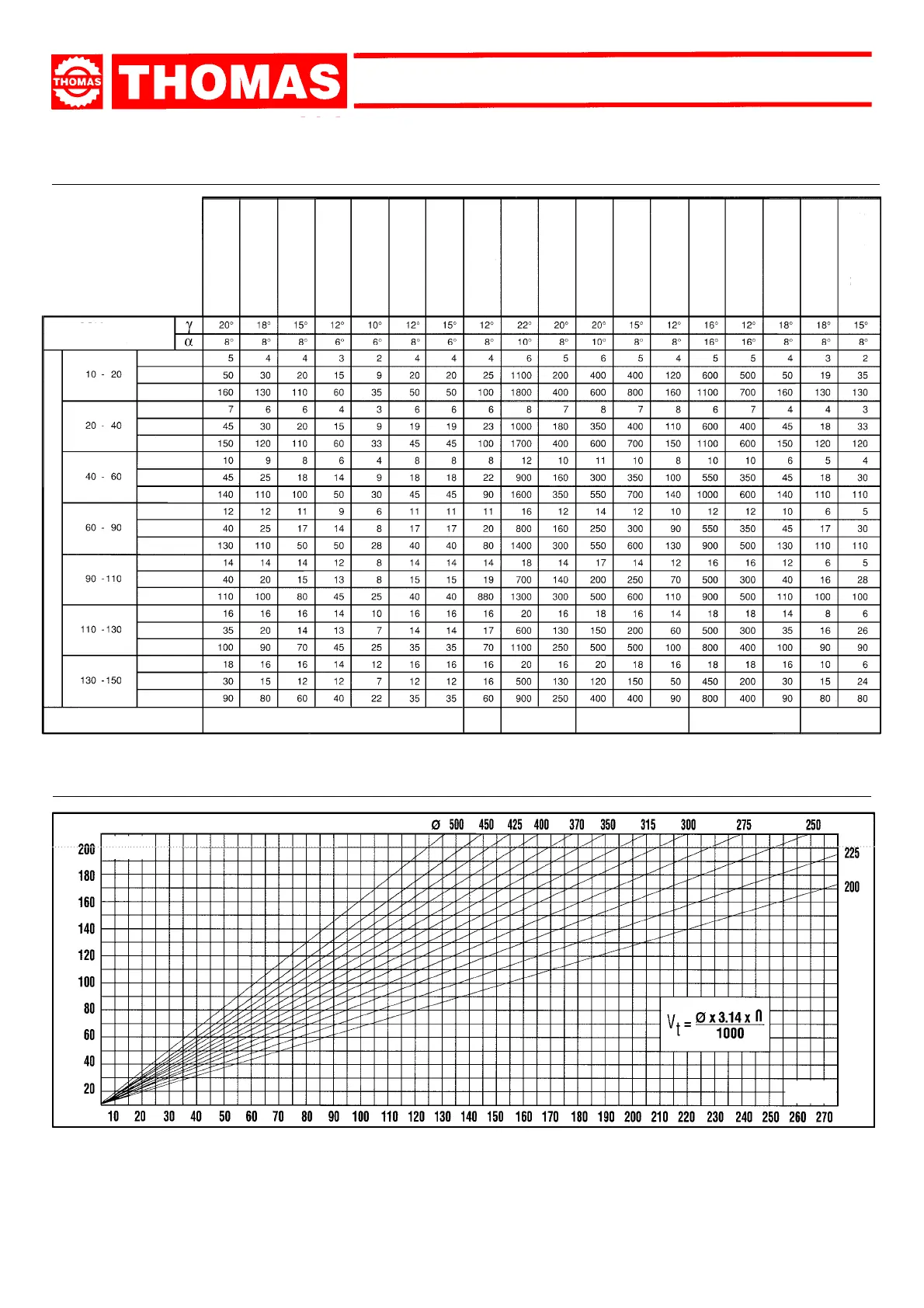

9.7.1 - RECOMMENDED CUTTING PARAMETERS

SECTION TO BE CUT (IN MM)

*T mm

Vt m/1'

*T mm

Av mm/1'

Vt m/1'

Av mm/1'

*T mm

Vt m/1'

Av mm/1'

Av mm/1'

*T mm

Vt m/1'

*T mm

Av mm/1'

Vt m/1'

*T mm

Vt m/1'

Av mm/1'

Av mm/1'

Vt m/1'

*T mm

Mild steel

R = 350-500 N/mm

2

Aluminium and alloys

R = 300-300 N/mm

2

Tubes and beams

0,025. D

R = 300-600 N/mm

2

Brass

R = 200-400 N/mm

2

Titanium and alloys

R = 300-800 N/mm

2

Tubes and beams

0,05. D

R = 300-600 N/mm

2

Alloyed brass

R = 400-700 N/mm

2

KEY

T Tooth pitch in millimetres

Av mm/min Advance in millimetres per minute

Vt m/min Cutting speed in metres per minute

Az Tooth advance

Ng/min Number of revs per minute

Z Number of teeth on the disk

p Tooth depth

Heat-treated steel

R = 950-1300 N/mm

2

Extra-hard steel

R = 950-1000 N/mm

2

Hard steel

R = 750-950 N/mm

2

Semi-hard steel

R = 500-700 N/mm

2

Grey cast iron

Aluminium and alloys

R = 200-400 N/mm

2

Copper

R = 200-350 N/mm

2

Phosphor bronze

R = 400-600 N/mm

2

Hard bronze

R = 600-900 N/mm

2

Vt m/min

n = g/min

d Diameter of the tooth fillet cone distance

h Tooth protrusion

γ Front rake

α Rear rake

N/mm Ultimate tensile stress

a-f Flat parts of the cutting edge

Ø Tube diameter or profile width

Austentic stainless

steel

R = 500-800 N/mm

2

Martensitic stainless

steel

R = 500-800 N/mm

2

CUTTING ANGLES

RECOMMENDED LUBRIFICANTS Emulsion - Cutting oil

Dry

Kerosene

Dry

Emulsion

Cutting oil Emulsion

Loading...

Loading...