Page 20 18728-D01

Single- and Dual-Axis Scanning Galvo Systems for Small Beam Diameters

4.4 Recommended Scanning Angles

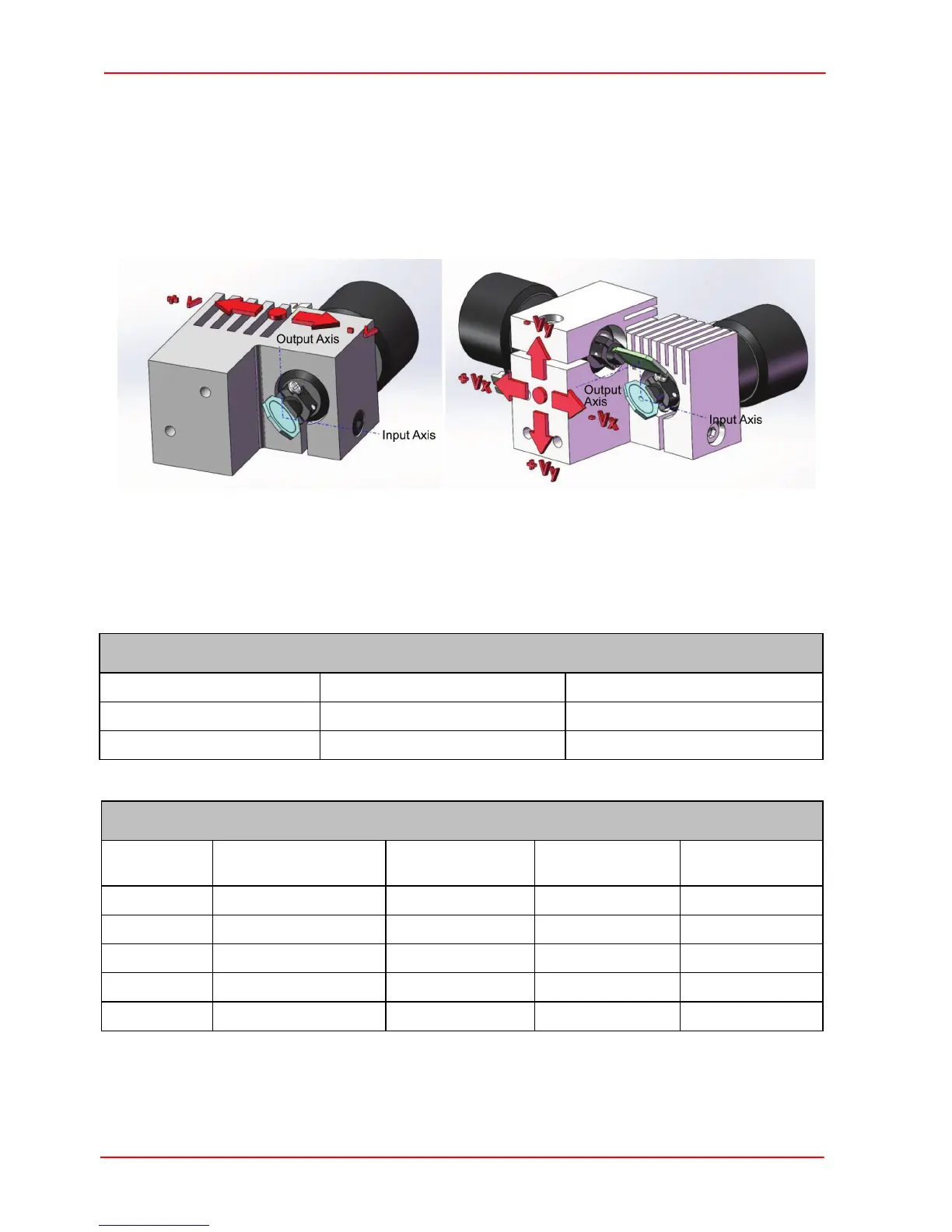

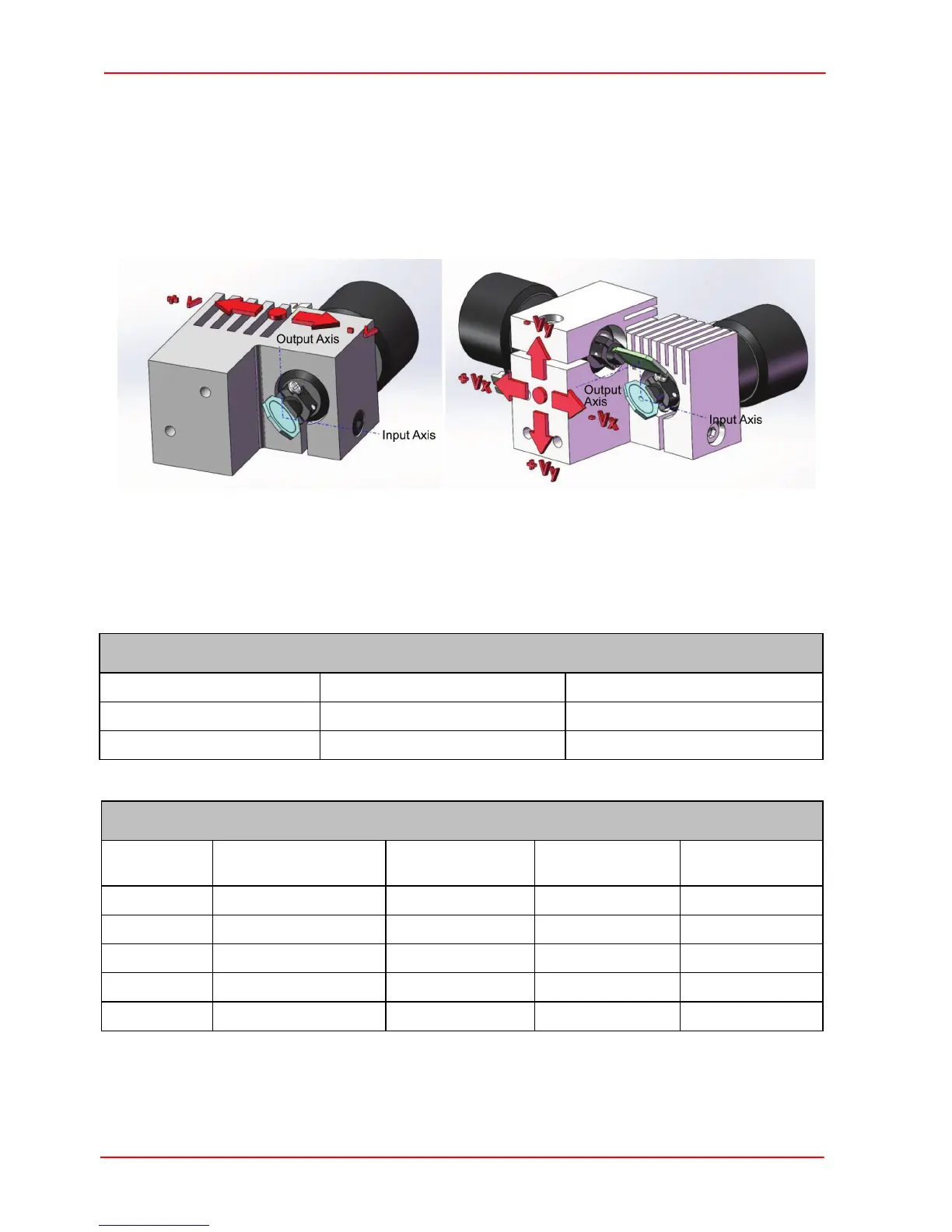

The ideal scanning angle is dependent upon a number of conditions. Firstly, the larger

the diameter of the input laser beam, the smaller the achievable scanning angle.

Secondly, the applied input voltage causes the laser beam to move away from the

center of the mirrors. The larger the input voltage then the greater the movement from

the center, as shown below.

Lastly, on dual-axis systems, there is an offset alignment between the X and Y axis

mirrors that also limits the scan angle.

The table below gives recommended scanning angles for various beam diameters.

GVS001, GVS101, GVS201 and GVS301,

Input Beam Diameter Mechanical Scan Angle Optical Scan Angle

4 mm and less ± 12.5° ± 25°

5 mm + 10°, -12.5° + 20°, -25°

GVS002, GVS102, GVS202 and GVS302,

Input Beam

Diameter

Mechanical

Scan Angle X

Optical

Scan Angle X

Mechanical

Scan Angle Y

Optical

Scan Angle Y

1 mm + 11.0°, - 12.5° + 22.0°, - 25° ± 12.5° ± 25°

2 mm + 10°, - 11.5° + 20°, - 23° ± 12.5° ± 25°

3 mm + 9.5°, - 10° + 19°, - 20° ± 12.5° ± 25°

4 mm ± 8.5° ± 17° ± 12.5° ± 25°

5 mm ± 8° ± 16° + 12.5°, -3° + 25, -6°

Loading...

Loading...