Triple Flail Maintenance Section 4-12

MAINTENANCE

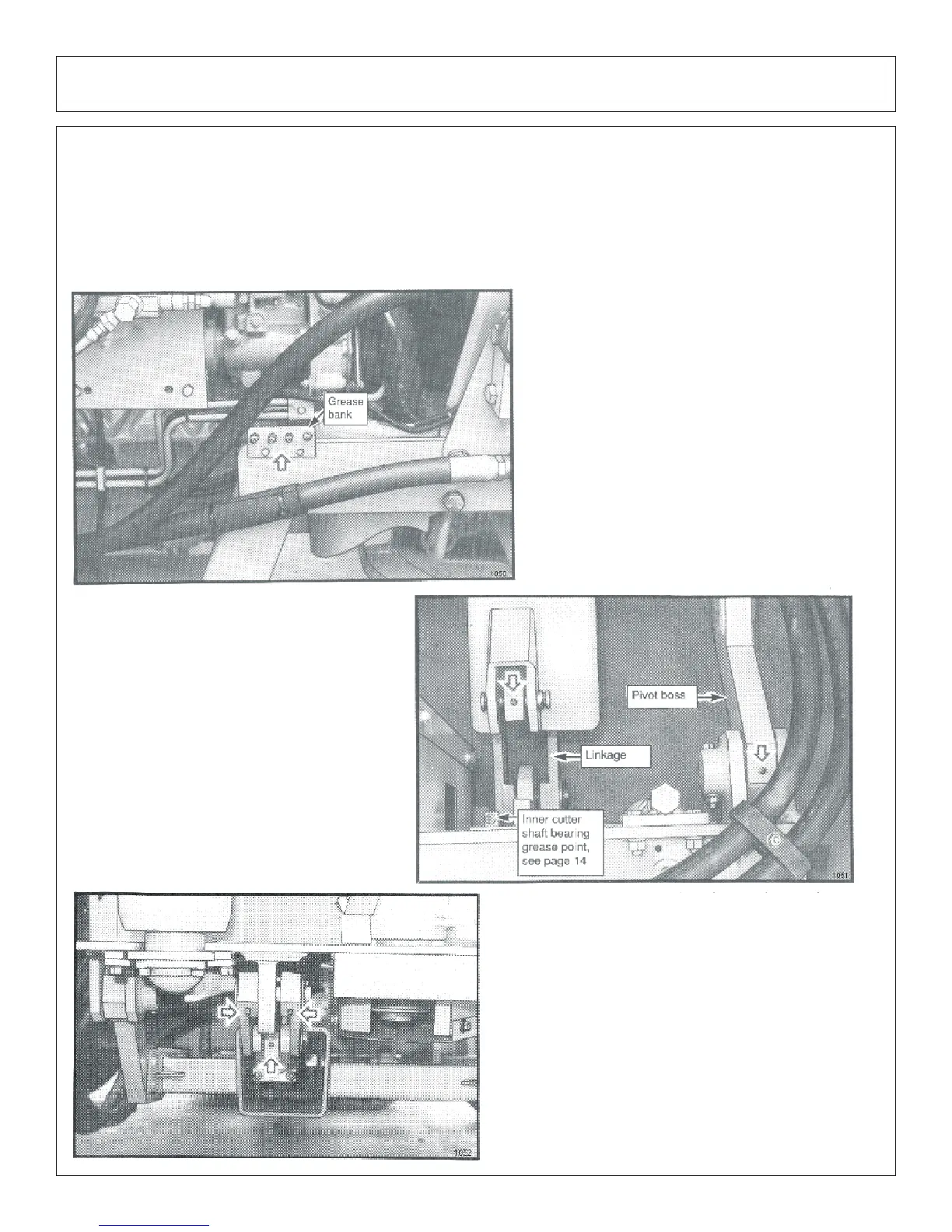

GREASING INNER AND OUTER DRAFT BEAM

PIVOT POINTS

Locate the grease zerks on the inner and outer draft beam pivot bosses. Inject

Lithium-Complex Extreme Pressure grease conforming to NLGI2-ISO 320

specifications into each zerk until grease protrudes from joints. Grease all pivots

daily or every 8 hours of service.

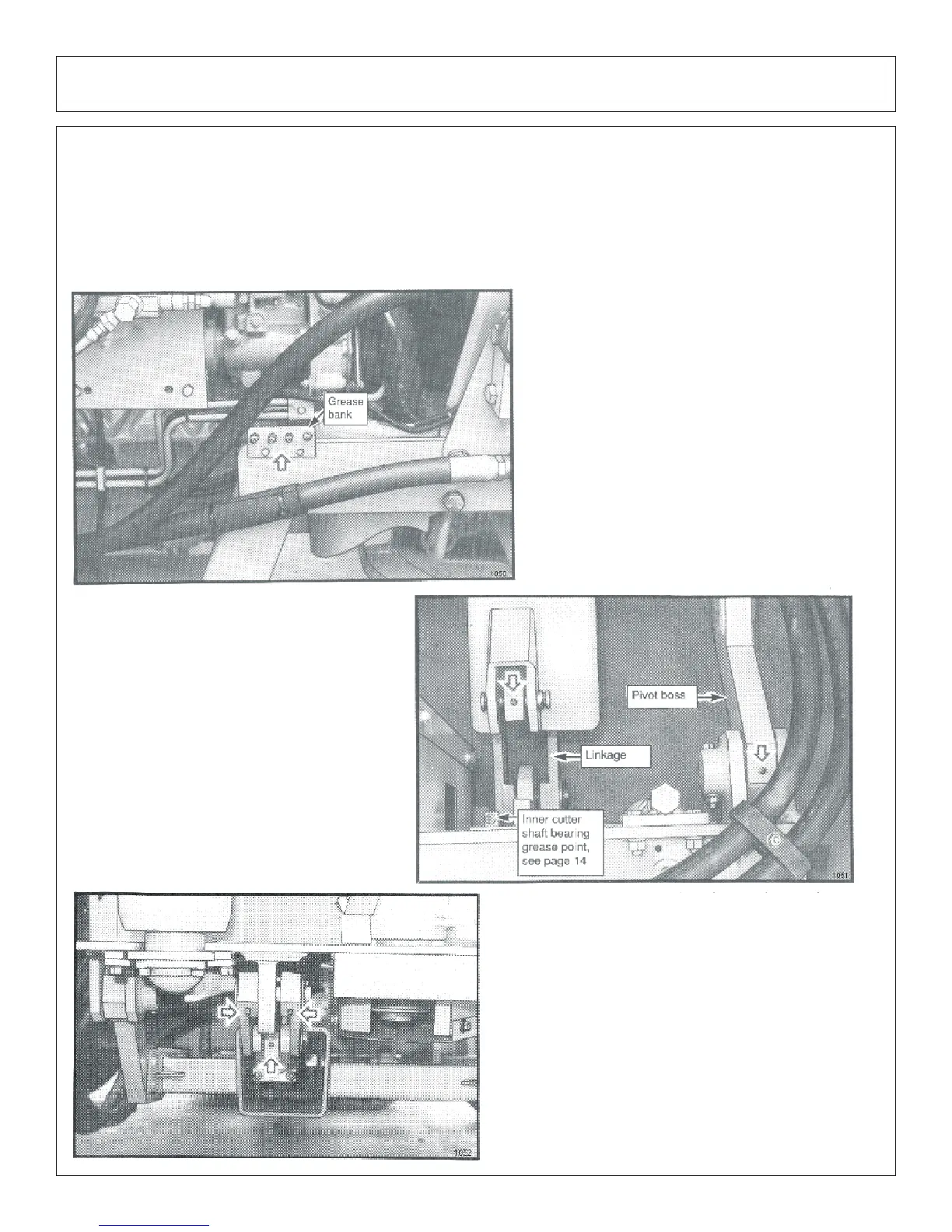

With the cutter head lowered, locate the

grease zerks on the linkage and pivot bosses.

Inject Lithium-Complex Extreme Pressure grease

conforming to NLGI2-ISO 320 specifications until

it protrudes from the ends. With the cutter head

in this position it is also possible to grease the

draft beam cylinder anchors and pins. Now

raise the cutter head to expose the remaining

zerks on the deck tilt linkages and on the other

end of the cylinder.

Loading...

Loading...