33 34

tcerroCgnorW

Air

Air

Air

Figure 7:

Correct installation of

the pipes

4.4.5. If the pump is to be used in an open circuit, the suction pipe diameter must be adequate

for the installation conditions. The suction pipe diameter should not be smaller than the suction

port diameter. When the suction pipe is bigger than the suction port, an adaptor must be

installed.

4.4.6. Model CD 32 and above, allow horizontal or vertical installations. However, the motor

must never be installed at a lower level than the base plate or in an inverted position.

4.4.7. Motors over 5 HP (4 kW) must be installed on a stand.

4.4.8. In order to minimize pump noise, we recommend the use of expansion joints on both

ends of the pump. The installation/foundation must be carried out as described in 4.5. Founda-

tion.

4.4.9. Install isolation valves on both sides of the pump to stop the system from getting empty

when the pump is to be removed to be cleaned, repaired or replaced.

4.4.10. Use a non-return valve (foot valve) to protect the pump against backflow.

4.4.11. Install the pipes so that no air bubbles are formed, particularly at the suction end of the

pump (Figure 7).

4.4.12. You should install a vacuum valve near the pump if the installation meets one of the

following characteristics:

● The downstream pipe is inclined downwards.

● There is a risk of syphon effect.

● Protection against dirty liquid backflow is needed.

4.4.13.

Before installing the pump, the suction pipe must be cleaned. When pipes carry impuri-

ties, it is needed to install a filter at 1.6~3.3 FT (0.5~1 m) from the pump inlet (particular-

ly recommended for pumps with a flow below 44.03GPM (10 m³/h)).

Installation, Operation and Maintenance Manual Installation, Operation and Maintenance Manual

4.4. Mechanical Installation

We recommend that our pumps are installed on a concrete foundation stand that is heavy

enough to provide permanent and rigid support to the whole pump. Foundation stands must be

capable of absorving any vibration, normal strain or shock . Concrete foundation stand surfac-

es must be entirely flat and even.

4.5. Foundation

ATTENTION:

Foundation and installation must be performed according to the instruc-

tions below. Otherwise, operating failures and pump components’ damage

may occur.

Place the pump on the foundation stand and fasten it. The whole of the pump base plate must

rest on the stand surface.

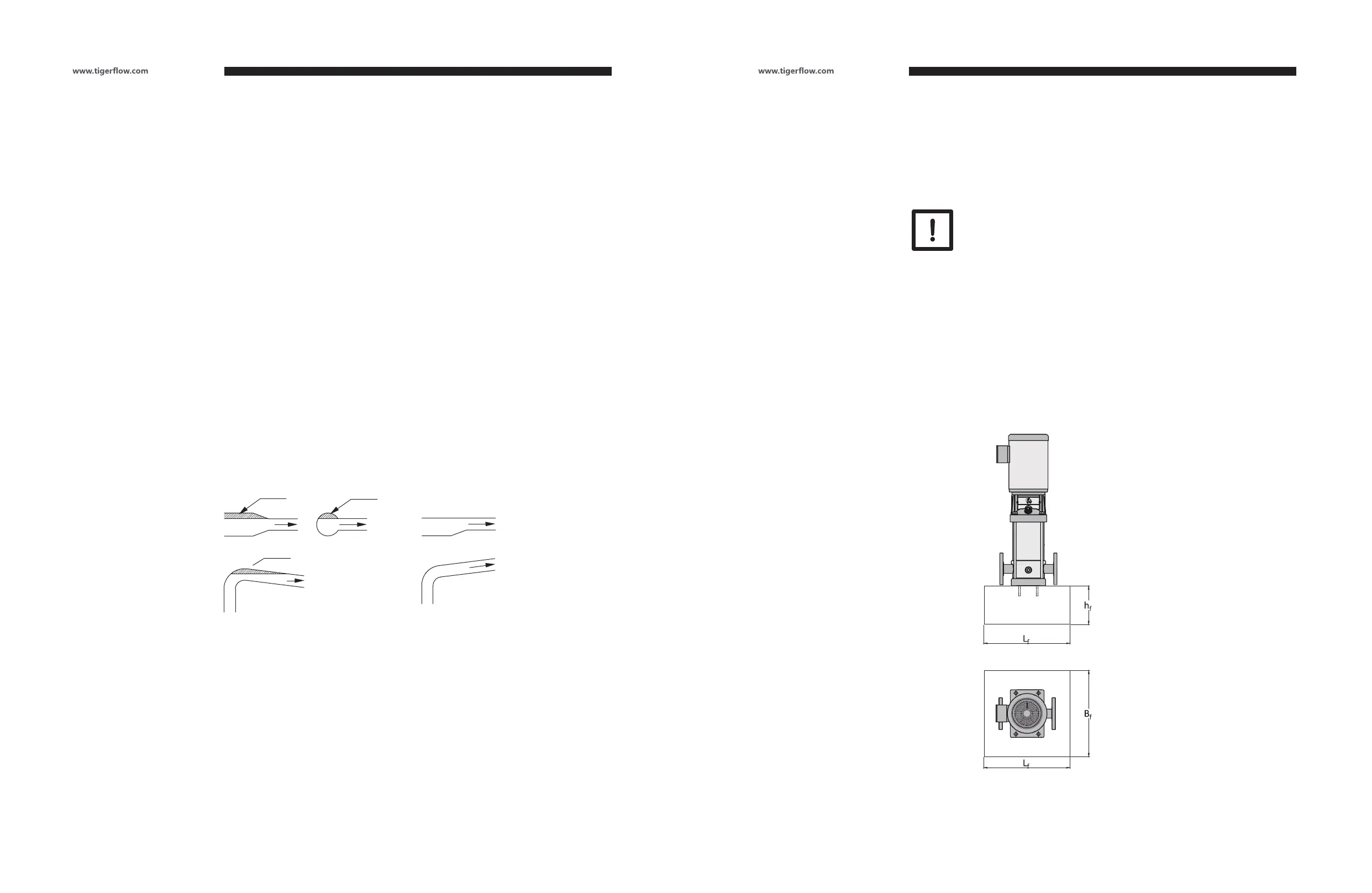

Recommended length and width are indicated at Figure 8. Note that the length and width of the

foundation for pumps with motor size ≤ 40HP (30 kW) must be 8in (200 mm) larger than the

base plate.

Figure 8:

Installing the pump

in vertical position

Loading...

Loading...