41 42

CD 32-85 process:

From model CD 32 and above, the pump is supplied with a fork shaped calibrated separator

that facilitates the motor coupling and replacement.

1. Remove the metallic coupling guards.

2. Untighten the bolts that hold the mechanical coupling.

3. Untighten the bolts that hold the motor in place and remove it.

4. Untighten the six screws that hold the seal into place (three on the shaft and three on the

top support). Extract the mechanic seal.

5. To install the new mechanic seal, insert it in the same position as the previous one.

6. Insert the three screws that hold the seal of the hydraulic pump head.

7. Tighten the screws that hold the mechanical seal of the pump shaft.

8. Lift the pump shaft and place the filler gauge below the seal collar.

9. Put the motor back into place and tighten the screws that secure the motor.

10. Position the mechanical coupling so that that there is the same gap on all the sides

(motor and hydraulic part).

11. Remove the filler gauge.

12. Place the metallic coupling guards and secure it by means of the side screws.

Installation, Operation and Maintenance Manual Installation, Operation and Maintenance Manual

6. MAINTENANCE

7. TROUBLESHOOTING

DANGER:

Make sure that the power supply has been switched off and that it cannot

be accidentally switched on before removing the terminal box cover and

before removing/dismantling the pump.

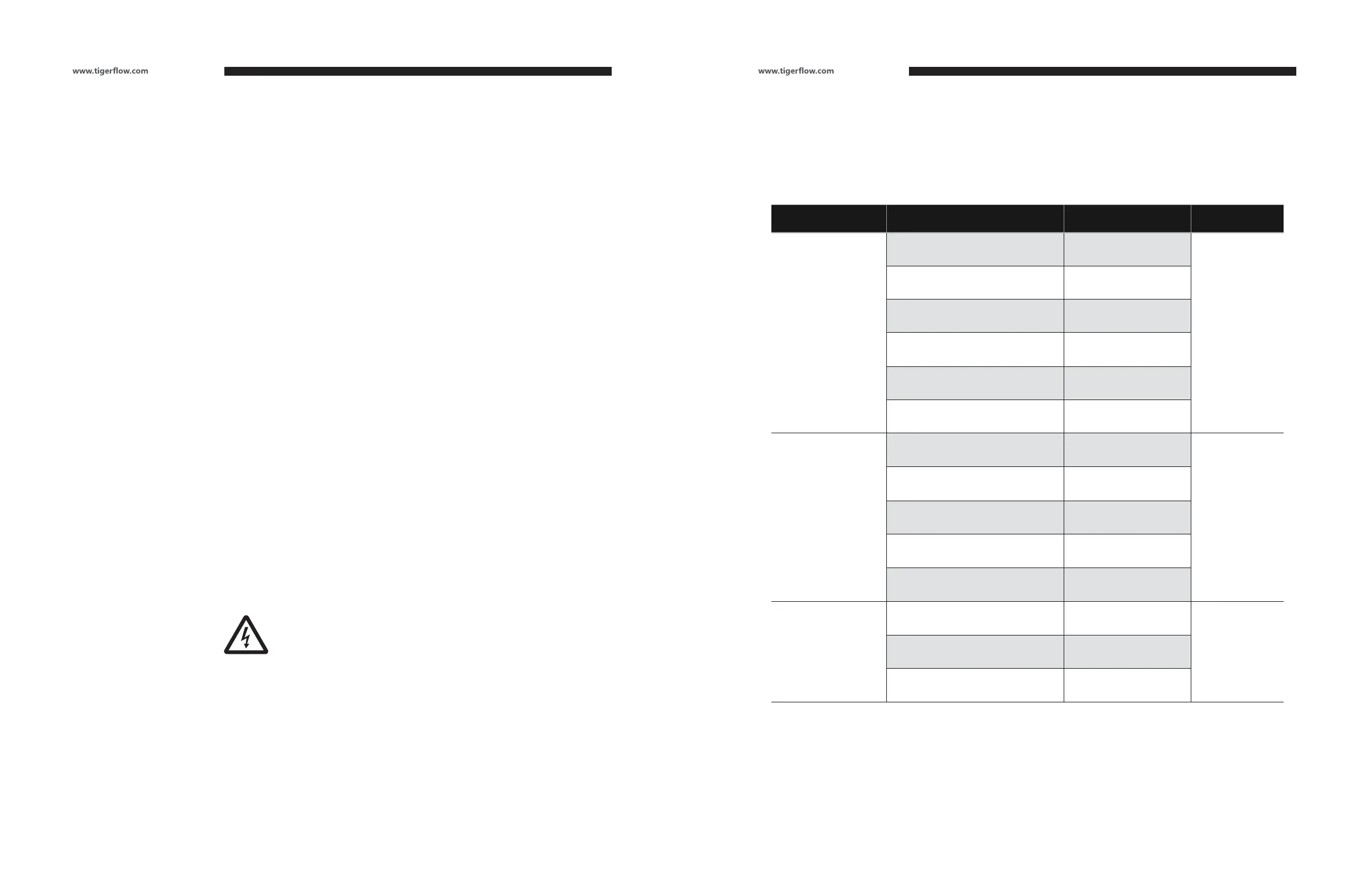

Fault

Cause Remedy Observations

a) Supply failure.

b) Fuses are blown.

c) Motor overloaded.

a) Check the power supply.

b) Replace fuses.

c) Check the system.

e) Repair the control circuit.

f) Replace the motor.

a) Replacefuses

b) Check power supply.

c) Add regulator.

e) Control circuit is defective.

f) Motor is defective.

a) Fuses are blown.

c) Cable connection is loose or faulty.

d) Motor winding is defective

e) Pump mechanically blocked.

d) Replace the motor.

b) Defects regular power supply.

c) Low voltage at peak times.

d) Main contacts in motor-protective circuit

breaker are not making contact or the coil

is faulty

In case d) and e),

the user should not

dismantle the pump

himself

2. Motor-protective circuit

breaker trips immediately

when power supply is

switched on.

3. Motor-protective circuit

breaker trips out occasion-

ally.

1. Motor does not run

when started.

b) Contacts in motor-protective circuit bre-

aker are faulty

d) Replace contacts or magnet-

ic oil.

b) Check the motor- protective

circuit breaker.

a) Set the motor- protective

circuit breaker correctly

c) Fasten or replace the cable

connection.

e) Remove the mechanical

blocking of the pump.

a) Motor-protective circuit breaker setting

is too low.

Loading...

Loading...