39

TTL758CHN

In

more

detail...

EN

Care and maintenance

Sprocket wheel

Guide bar and saw chain maintenance

NOTE: It is not necessary to remove the saw chain (3) to

lubricate the sprocket wheel. Lubrication can be done on the

job.

1. Clean the sprocket wheel (5).

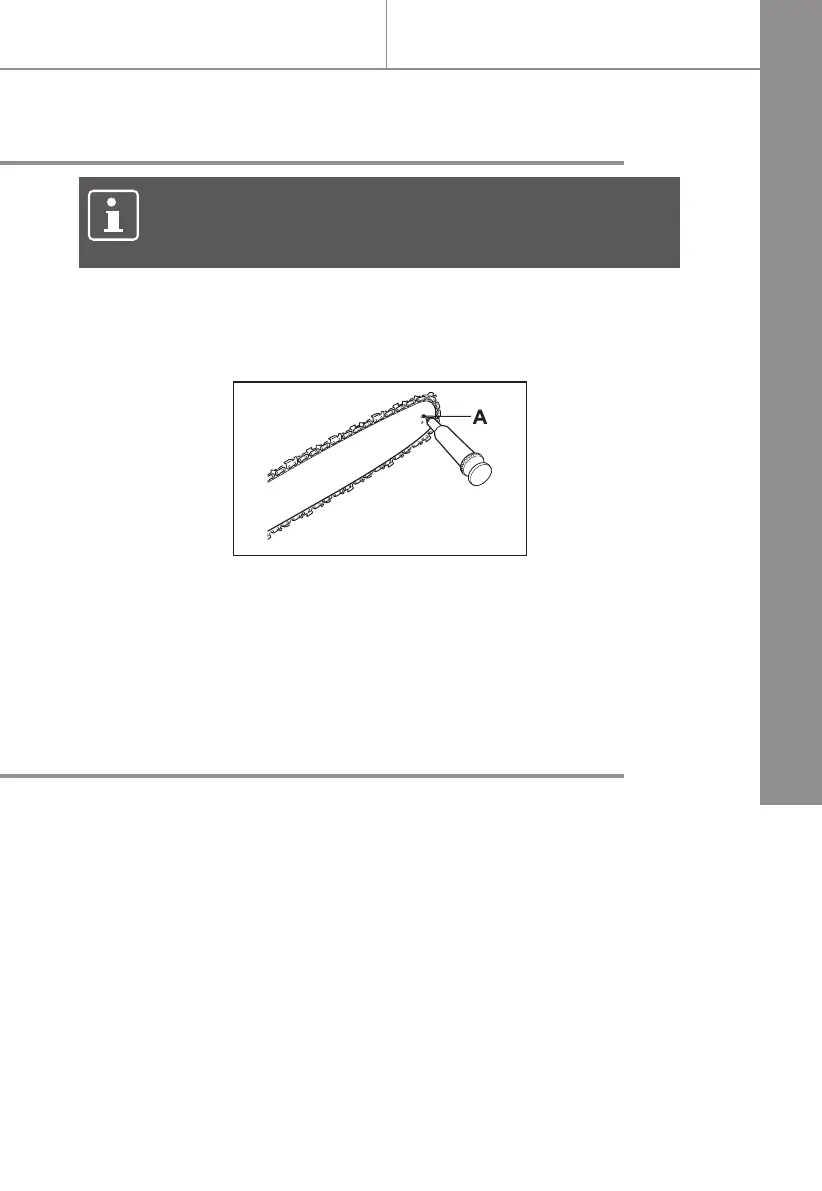

2. Using a disposable lube gun, insert the needle nose into the

lubrication hole (Fig. 13, A) and inject grease until it appears at

the outside edge of the sprocket (5) (Fig. 13).

3. Make sure that the chain brake is disengaged. Rotate the saw

chain (3) by hand. Repeat the lubrication procedure until the

entire sprocket (5) has been greased.

1. Most guide bar problems can be prevented merely by keeping the

product well maintained. Incorrect ling and non-standard cutter and

depth gauge settings are the causes of most guide bar problems,

primarily resulting in uneven bar wear. As the bar wears unevenly,

the rails widen, which may cause the chain to clatter and make it

dicult to complete straight cuts. If the guide bar is insuciently

lubricated and the product is operated with a saw chain which is

too tight, this will contribute to rapid bar wear. To help minimise

bar wear, maintenance of the guide bar as well as the saw chain is

recommended.

Fig. 13

Loading...

Loading...