Page 21@)1&/2:(+.:4=&A02'/.)+'B&6=24'2&:4==&CD###DE#FDFEC#,Item 57863 57864

GH@<IJKHLMI<MHMN< OHGLN&P<QRLMSP<QRLMS&ILTG G<IUT

1. Press (and hold) Trigger and contact the area

to be welded with electrode wire to ignite arc.

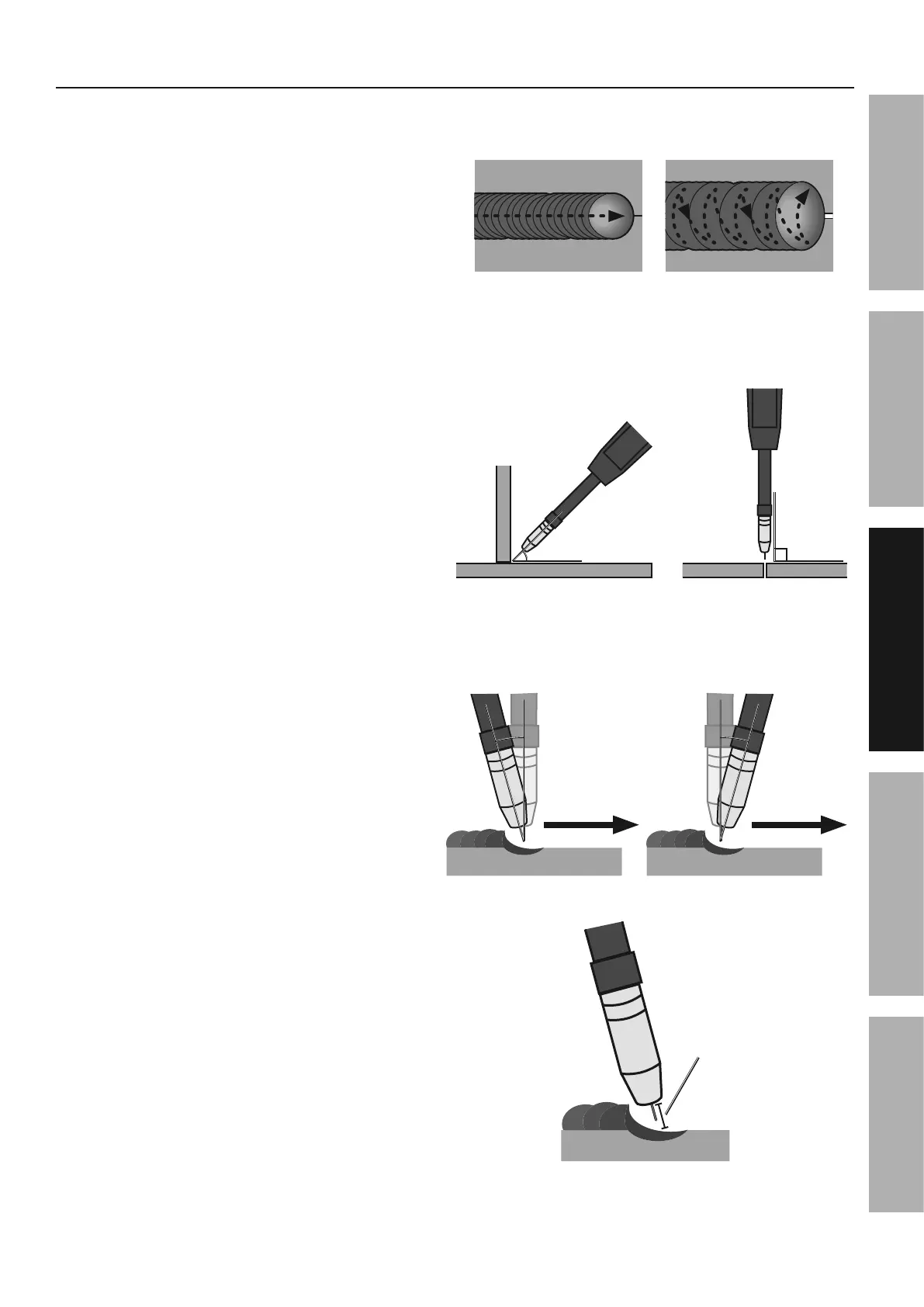

2. For a narrow weld, you can usually draw the wire in

a steady straight line.

This is called a stringer bead.

For a wider weld, draw the wire back and forth

across the joint.

This is called a weave bead and takes

practice to perform properly.

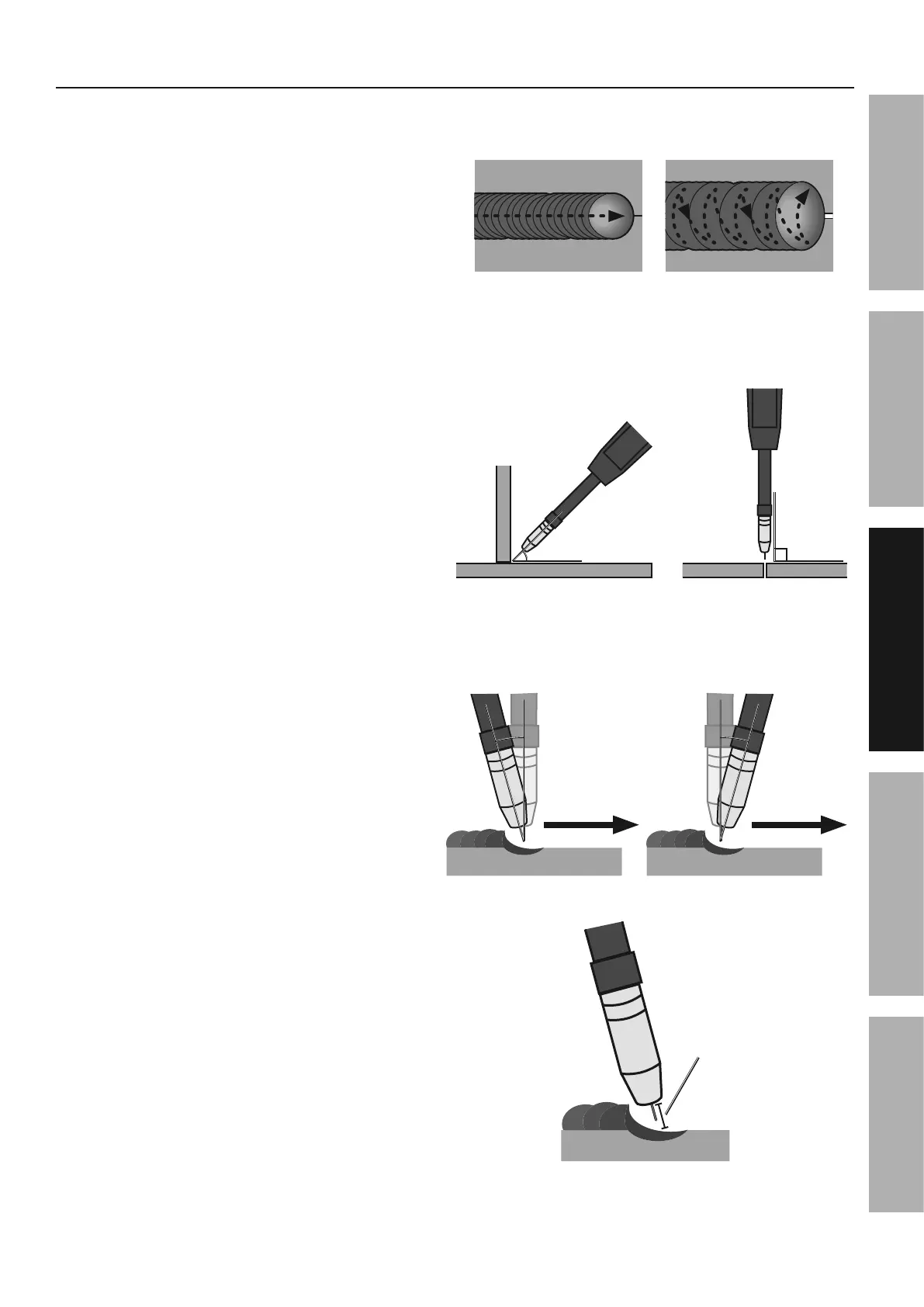

3. Direct the welding wire straight into the joint. This

gives an angle of 90° (straight up and down)

for butt (end to end) welds, and an angle

of 45° for fillet (T-shaped) welds.

4. For MIG welding using solid wire and

shielding gas, the end of the MIG Gun

should be tilted so that wire is angled

anywhere in-between straight on and

15° away from the direction you are welding.

The amount of tilt is called the push angle.

5. When using flux-cored wire without

shielding gas, the end of the MIG Gun

should be tilted so that wire is angled

anywhere in-between straight on and

15° in the direction you are welding.

The amount of tilt is called the drag angle.

6. The Contact Tip should remain within 1/2″

of the work surface. This distance is called

CTWD - Contact Tip to Work Distance.

'/1.+921&324> *24Y2&324>

P2=>&KLS&S0+&4+9=2'B&&

Y.2*2>&81);&81)+/&)8&*2=>&_).+/,

%!k

8.==2/&*2=>&_).+/

90°

30//&*2=>&_).+/

NIPR&&

(up to 1/2")

P2=>&

R.12:/.)+

T0'(&H+9=2T0'(&H+9=2

FDC!kFDC!k

P2=>&

R.12:/.)+

R149&H+9=2R149&H+9=2

FDC!kFDC!k

G)=.>&P.12&*./(&G(.2=>.+9&S4' @=0\DN)12>&P.12&*./()0/&S4'

O4'.:&P2=>.+9&I2:(+.A02

Loading...

Loading...