Page 23@)1&/2:(+.:4=&A02'/.)+'B&6=24'2&:4==&CD###DE#FDFEC#,Item 57863 57864

GH@<IJKHLMI<MHMN< OHGLN&P<QRLMSP<QRLMS&ILTG G<IUT

P2=>.+9&I.6'

A good way to test welding technique is to examine a

weld’s appearance after it has cooled and the slag

has been removed. Then, better welding can be

learned by adjusting your weld technique to remedy

any problems found.

N=24+.+9&/(2&P2=>

IW&TV<-<MI&G<VLWUG&LMcUVJ5&

N)+/.+02&/)&*241&HMGLD4661)Y2>&

'482/X&9)99=2'&4+>&61)/2:/.Y2&*241&

*(2+&:=24+.+9&4&*2=>,&&

G641]'&)1&:(.6'&;4X&8=X&*(2+&:=24+.+9,

1. A weld from flux-cored wire will be

covered by slag. Use a chipping hammer

to knock this off. O2&:41280=&+)/&/)&

>4;492&/(2&*2=>&)1&34'2&;4/21.4=,

2. Use a wire brush to further clean the weld

or use an angle grinder (sold separately) to

shape the weld.

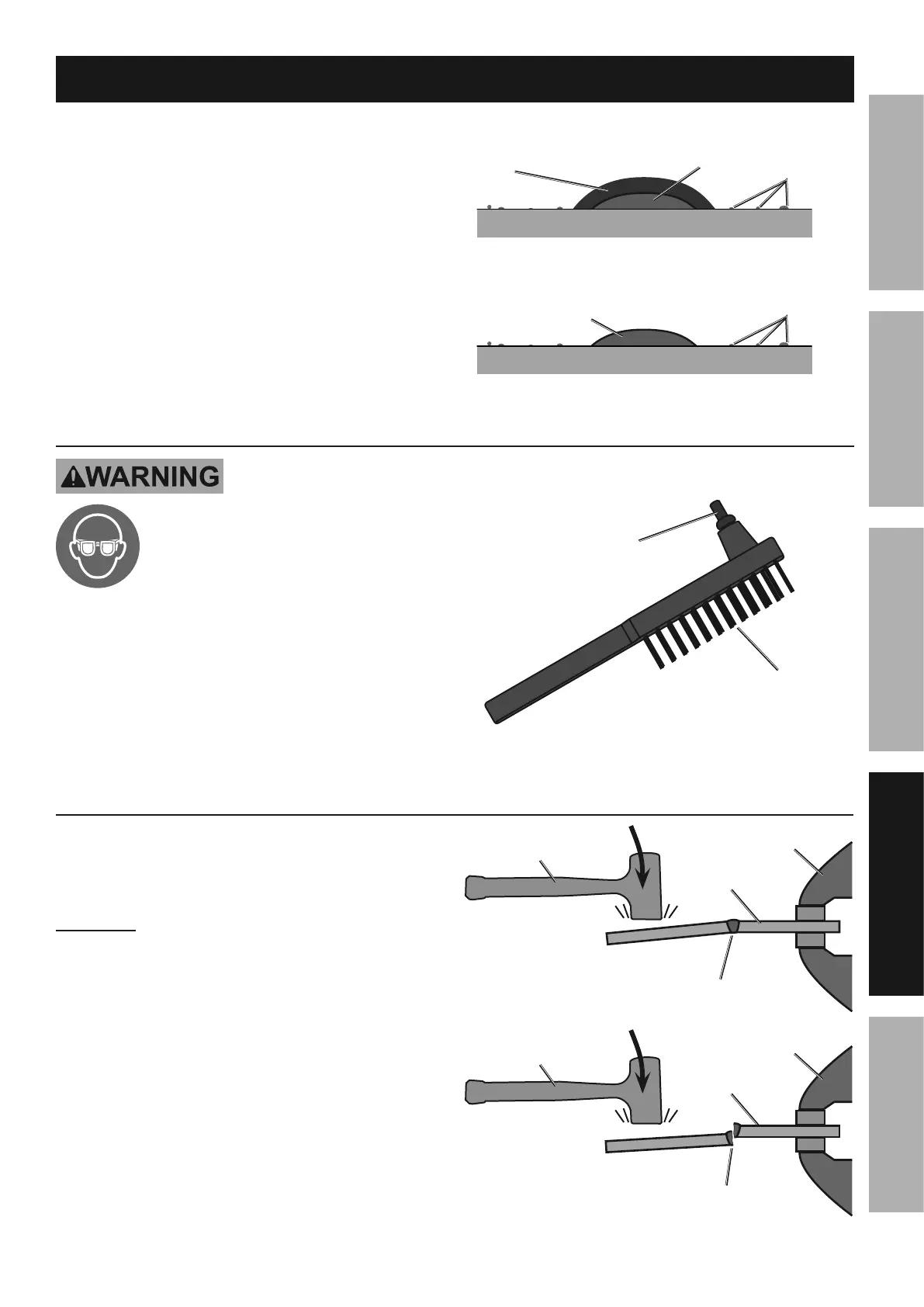

G/1.]2&I2'/

H&/2'/&*2=>&)+&4&TL<N<&W@&GNVHT&:4+&32&/2'/2>&3X&

0'.+9&/(2&8)==)*.+9&61):2>012,

P<HV&HMGLDHTTVW-<R&GH@<IJ&SWSSQ<G&

RUVLMS&I^LG&TVWN<RUV<,

PHVMLMSi&&IW&TV<-<MI&G<VLWUG&LMcUVJ5&&I(.'&

/2'/&PLQQ&>4;492&/(2&*2=>&./&.'&6218)1;2>&)+,&&

I(.'&/2'/&.'&WMQJ&4+&.+>.:4/)1&)8&*2=>&/2:(+.A02&

4+>&.'&+)/&.+/2+>2>&/)&/2'/&*)1].+9&*2=>',

1. After two scraps have been welded together and the

weld has cooled, clamp one scrap in a sturdy vise.

2. Stay clear from underneath while you strike

the opposite scrap with a heavy hammer,

preferably a dead-blow hammer.

3. A SWWR&P<QR will deform but not break,

as shown on top.

A TWWV&P<QR will be brittle and snap at the weld,

as shown on bottom.

:=4;6

GNVHT&

*)1]6.2:2

SWWR&P<QR&&

32+>'&4+>&.'&+)/&31.//=2

>24>D3=)*&(4;;21

:=4;6

GNVHT&

*)1]6.2:2

TWWV&P<QR&&

'+46'&)1&:14:]'

>24>D3=)*&(4;;21

A typical solid wire (GMAW) weld &

328)12&:=24+.+9,

34'2&;2/4=

*2=>&324>

'64//21

A typical flux-cored wire (FCAW) weld &

328)12&:=24+.+9,

34'2&;2/4=

*2=>&324>

'=49

'64//21

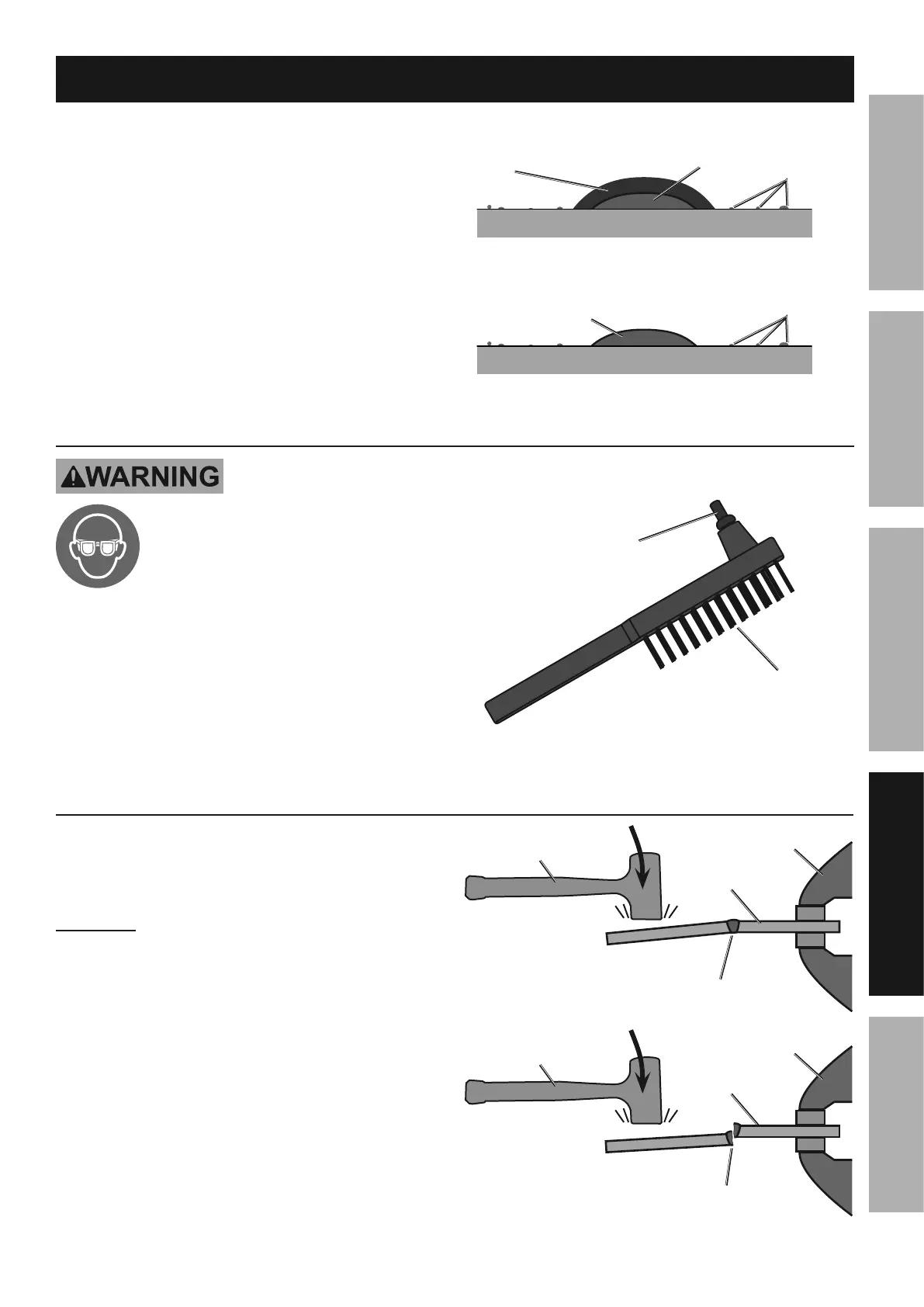

N(.66.+9&

^4;;21

P.12&O10'(

Loading...

Loading...