ENGLISH

ENGLISH

30

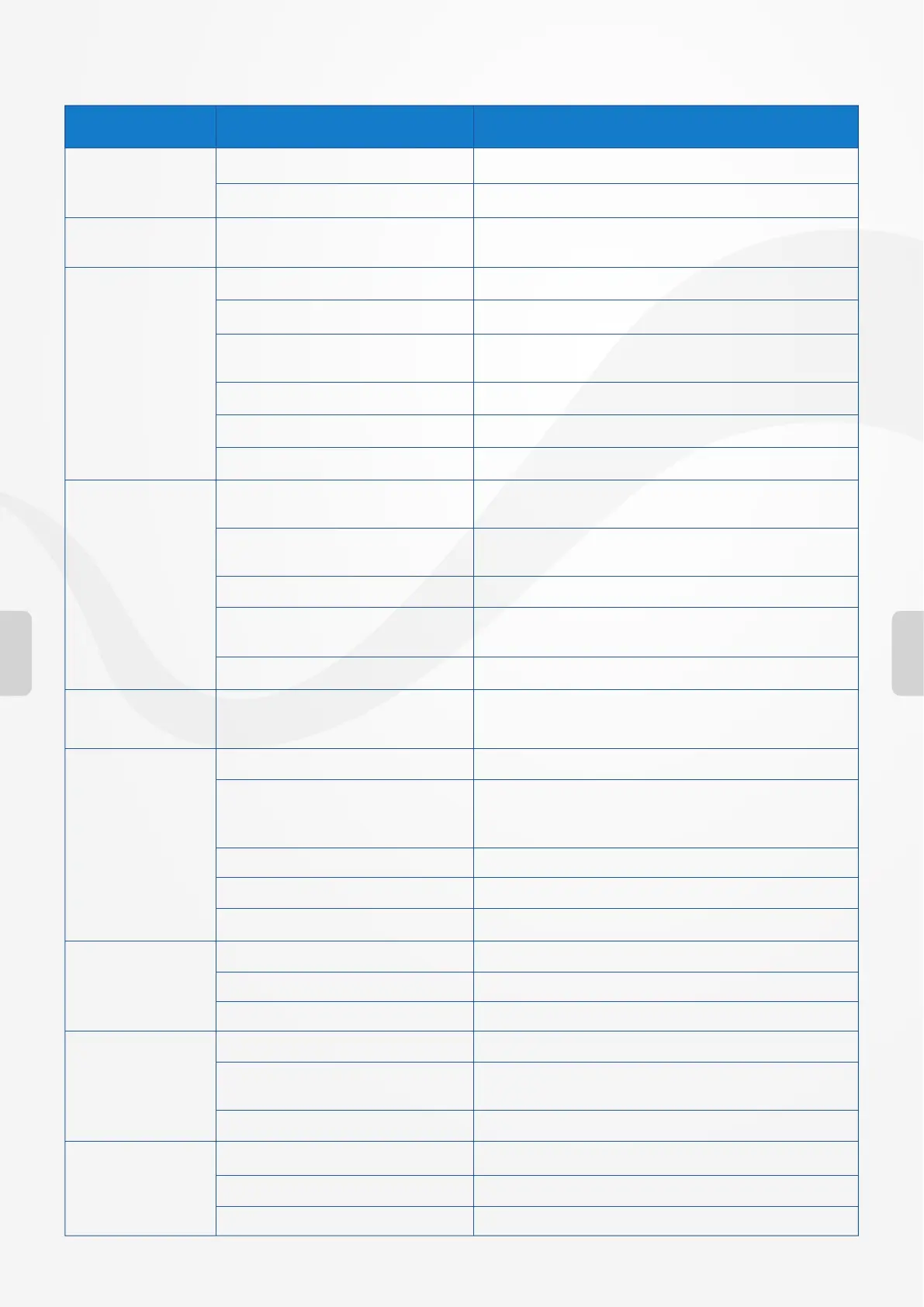

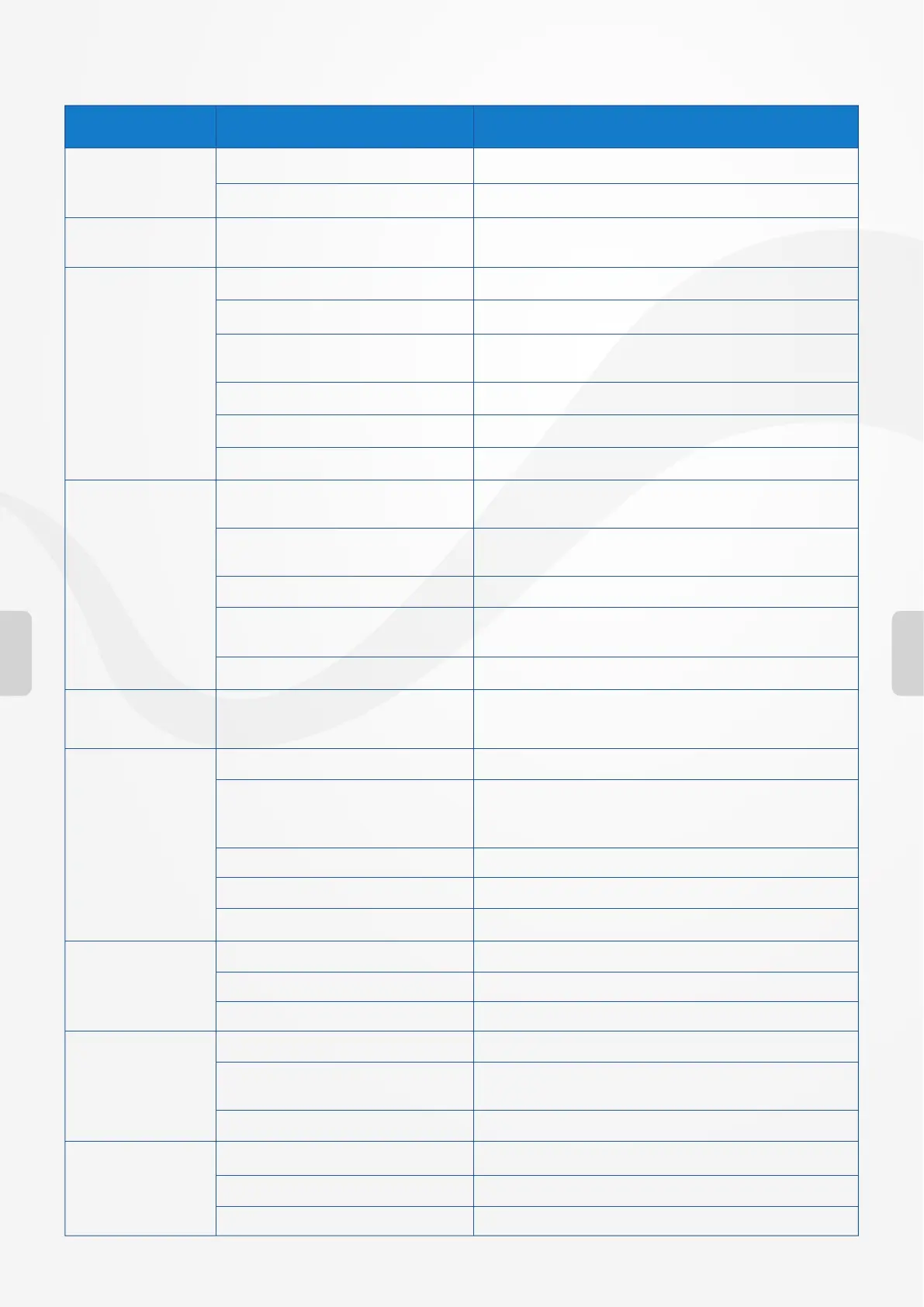

14. TROUBLESHOOTING

PROBLEM ORIGIN SOLUTION

6. Chlorides in

outlet water

(salty taste).

7. Iron in the

outgoing water.

8. Excess water

or overflow in the

salt deposit.

9. The softener

does not suction

the brine

10. Continuous

regeneration.

11. Continuous

drainage of water

into the drain or

salt tank.

12. Equipment

doesn’t perform

a bed filter

cleaning

13. Water leakage

in drain outlet.

Increase the quick wash duration.Inadequate regeneration.

Sanitize tank. Contact with TS.Resin dirty.

Check regeneration cycles. Increase the quick

wash duration. Sanitize. Contact with TS.

Resin dirty.

Correct refill time. Contact with TS.Excessive refill time.

Reduce pressure to 4 bar. Contact installer or TS.Excessive inlet pressure.

See point 9.Insufficient brine suction.

Contact with TS.Obstruction of the salt valve.

Contact with TS.Inadequate injector.

Contact with TS.Blocked programmer.

Increase pressure to 2 bar minimum.

Inlet water pressure insufficient.

Tighter connections in the suction line and verify

seal. Contact with TS.

Air in the brine suction line.

Check and/or clear drain outlet.Exit to drain blocked.

Contact with TS.Injector blocked.

Clean probe/valve. Contact with TS.

Aspiration valve / probe

blocked.

Replace valve main body.Internal leak on valve.

Contact with TS.Dirtiness inside valve.

Change the programmer. Contact with TS.

The programmer does not

function correctly.

Contact with TS.Adjustment of the ceramic disc.

Contact with TS.Valve blocked.

Check the electrical installation.Failure in the electric connection.

Replace the programmer. Contact with TS.Faulty programmer.

Reprogram the current time.Temporal power suppy cut.

14. Toothed gear

turns constantly.

Replace electronic board and display.Failure of electronic board.

Check internal wires.Internal wires desconected.

Repair toothed wheel.Toothed gear damaged.

Evacuar totalmente el aire del tanque.There is air in the equipment.

Change the DLFC.

Too much flow on Backwash

cycle.

Replace the upper crepine.Crepina superior dañada.

Set the by-pass in position closed until power

supply is back.

Power supply cut during

backwash or quick wash

Loading...

Loading...