17

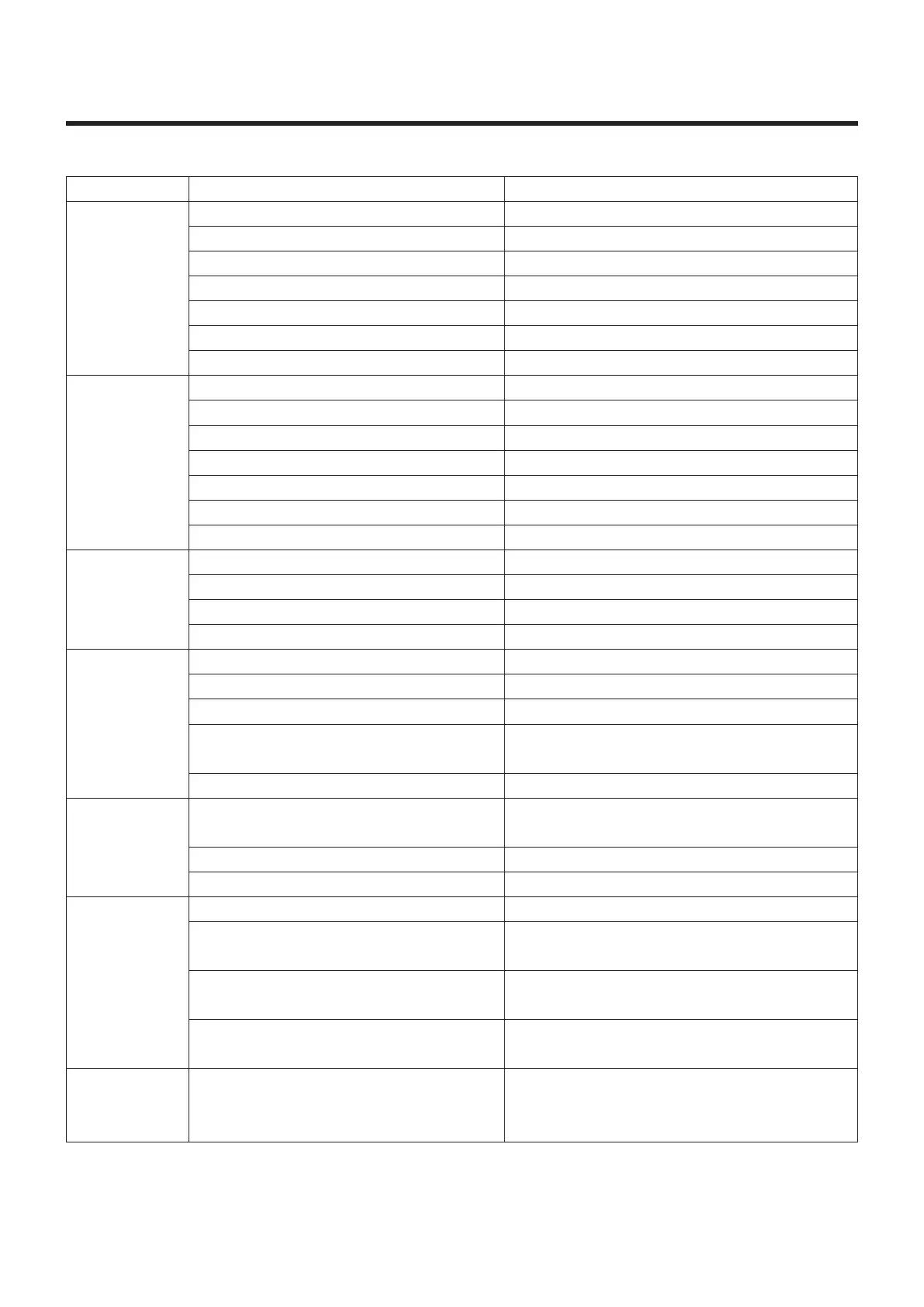

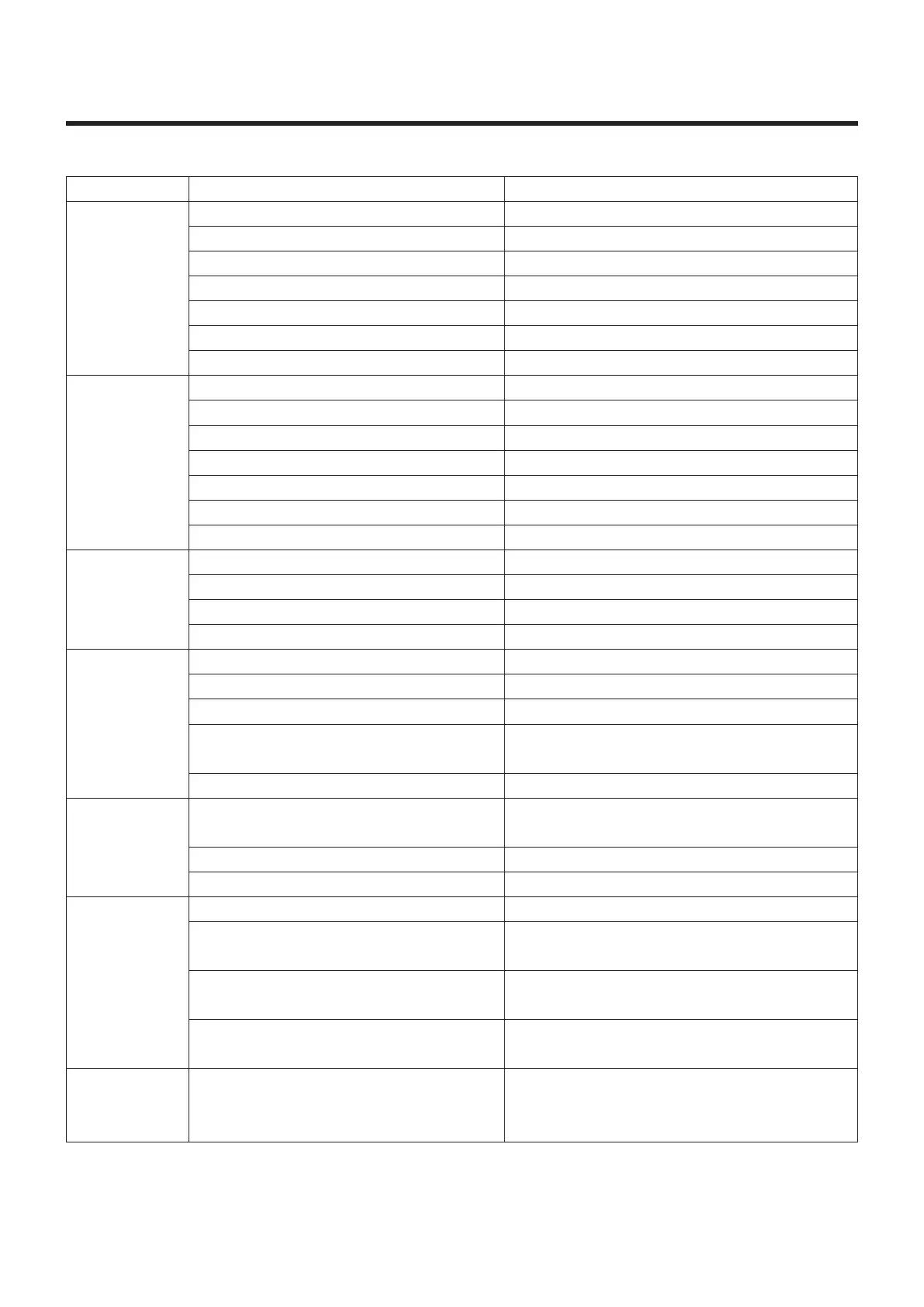

TROUBLESHOOTING

Problem

Cause Remedy

Engine fails to

start

Spark plug wire disconnected Attach spark plug wire securely to spark plug

Out of fuel or stale fuel Fill with clean, fresh gasoline

Fuel valve not in ON position Fuel valve must be in ON position

Choke lever not in CLOSE position Choke level must be in CLOSE position for a cold start

Blocked fuel line Clean the fuel line

Fouled spark plug Clean, adjust gap, or replace

Engine flooding Wait a few minutes to restart, but do notprime

Engine runs

erratically

Spark plug wire loose Connect and tighten spark plug wire

Unit running with Choke lever in CLOSE position Move choke lever to OPEN position

Blocked fuel line or stale fuel Clean fuel line. Fill tank with clean, fresh gasoline

Vent plugged Clear vent

Water or dirt in fuel system Drain fuel tank. Refill with fresh fuel

Dirty air cleaner Clean or replace air cleaner

Improper carburetor adjustment Refer to Engine Manual

Engine

overheats

Engine oil level low Fill crankcase with correct oil

Dirty air cleaner Clean air cleaner

Air flow restricted Remove housing and clean

Carburetor not adjusted properly Refer to Engine Manual

Chipping action

too slow, or

cutting disk

stalls, or no

material is

discharged

The engine speed is too slow causing belt to slip

Run the engine at full throttle

Drive Belt loose or damaged Tighten or replace drive belt

Knives dull or damaged Sharpen or replace knives

Cutting disk jammed by debris from the feed

hopper and discharge chute

Remove any built-up debris and turn cutting disk with a

wooden stick to be sure it turns freely

Discharge chute clogged Clean out debris

The belt frays or

rolls over the

pulley

The rotor drive pulley groove may be nicked

Check the drive belts for wear and hard spots. File off

any nicks on the pulley

The drive belts may be stretched Replace the drive belts

The pulleys may be misaligned Adjust the pulleys

Vibrate and

move about

excessively with

unusual noise

when working

Knives dull or damaged Sharpen or replace knives

Knives is not properly seated on thecutting disk

Loosen the knives mounting screws, reset the knives

and tighten the screws

The gap between the knives and wear plate is

too large

Adjust the gap

Rotor overloaded with material

Allow unit to clear itself before adding more material to

the hopper

Chipper Knives

are hitting the

wear plate

The gap between the knives and wear plate is

set incorrectly.

Adjust the gap.

Loading...

Loading...