6

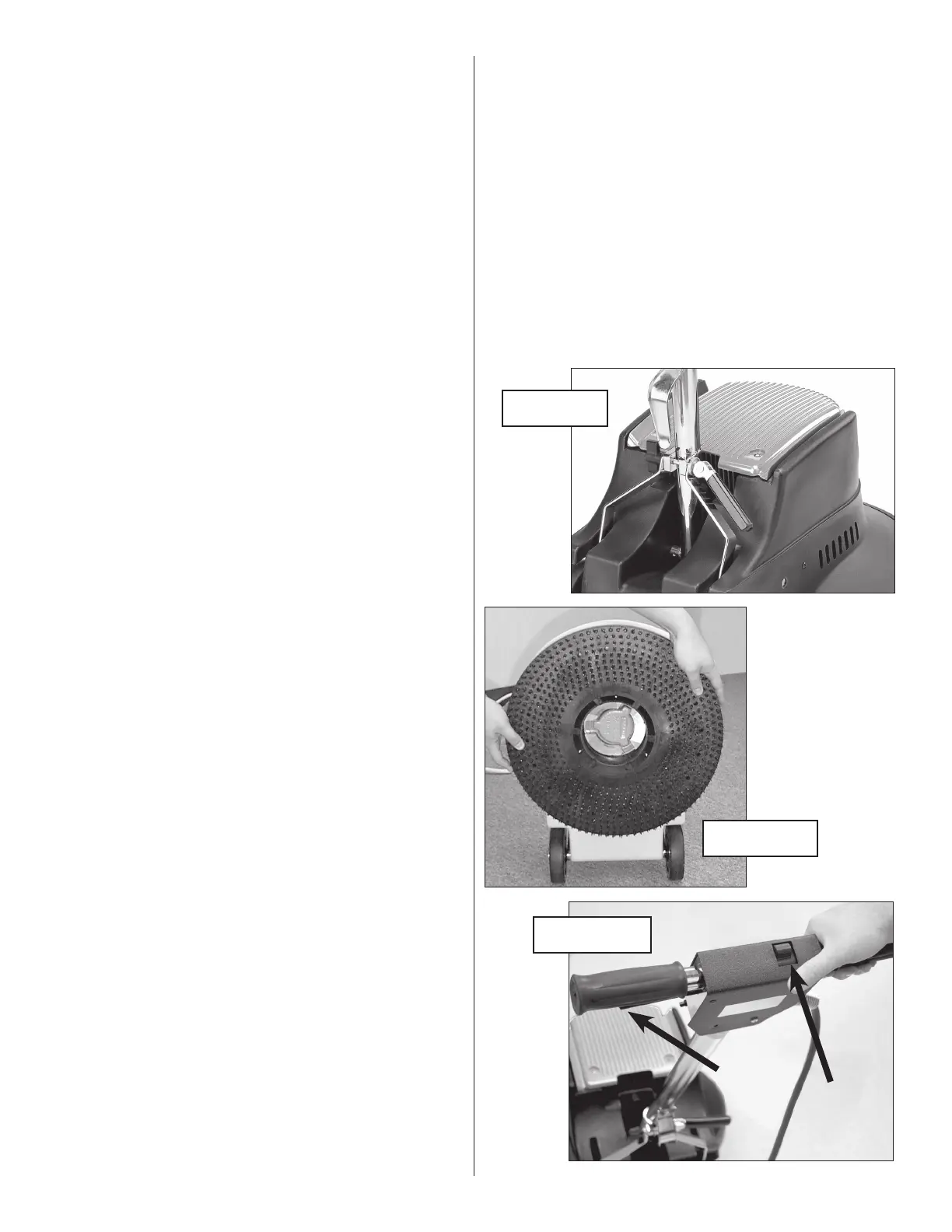

PREPARE THE MACHINE FOR

OPERATION

To attach the drive block or brush or other attachment, be sure

the handle is “locked” in the upright position (See picture #1).

Lay the floor machine on its back with the handle lying on the

floor, this exposes the driving plate on the underside of the floor

machine. Holding the drive block, brush or attachment in both

hands and straddling the motor with your back to the handlebox,

bend over and fit the three slots of the clutch plate (build into the

back of the brush) over the three lugs of the driving plate. Turn

the drive block, brush or attachment counter-clockwise as far as

it will go until it is seated in the ready-to-use position. (See pic-

ture #2) CAUTION: This is the only proper way to install a drive

block, brush or attachment. NEVER put a drive block, brush or

attachment on the machine by placing it on the floor and mov-

ing the running machine over it, or by placing the machine over

the block or attachment and then starting the motor. Return the

floor machine to upright position and adjust handle to operating

position. Recommended handle position is close to the waist with

arms extended down. Lock the cam release lever into position.

NOTE: The hardened steel cam release lever does not require

extreme tightening to effectively hold the handle in position. Over-

tightening will shorten the functional life of the lever. To remove

drive block, brush or attachment: Lay the floor machine on it’s

back again and disengage clutch plate slots from driving plate

lugs by turning clockwise.

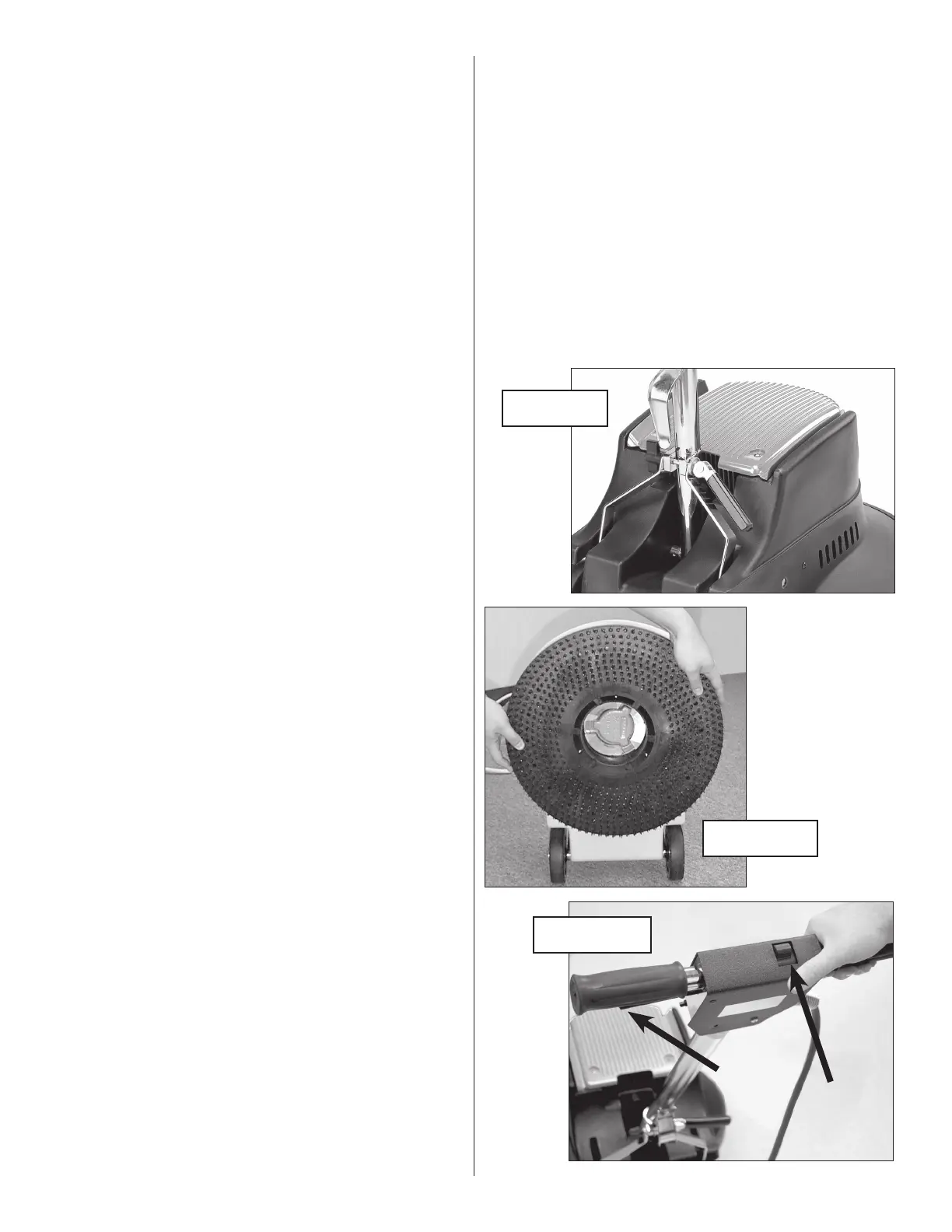

HOW TO OPERATE THE MACHINE

First install the pad driver and pad, brush or other attachments to

be used. Plug the machine in as directed and lower the handle

to the desired operating height and lock in place using the cam

lever handle. Push the safety switch forward (see picture #3)

and squeeze the switch triggers beneath the handle grips. This

activates the motor and starts the block, brush or attachment in

operation. Each time you release the triggers the safety switch

will reset. You will need to follow the direction above to restart

the machine. CAUTION: When leaving the machine unattended,

disconnect the wall plug and return the handle to the “locked”

upright position to prevent accidental starting.

TO GUIDE YOUR FLOOR MACHINE

To Right: raise handle slightly. The higher the handle is lifted,

the faster the machine will move to the right. To Left: to change

direction, lower the handle until the machine travels to the left.

The more the handle is lowered, the faster the movement to the

left.

TO INSTALL THE OPTIONAL SOLUTION

TANK

Mount the solution tank to the front of the handle and attach with

mounting brackets and knobs. Position the solution tank control

handle horizontally and below the switch lever of the machine

and adjacent to the right handle grip. Remove the plug from the

motor housing and insert the (long) extension tube adaptor and

secure at bottom of machine with the retainer. The solution tank

should be used only with a showerfeed drive block or brush.

TRANSPORTING THE MACHINE

Place the handle in the upright position. Lock the handle cam

release lever. Tip the machine back and transport on the wheels.

MAINTENANCE

Once a month remove the motor cover and vacuum out any

dust or debris which has accumulated on the motor. Replace

the motor cover by setting it over the holes in the housing and

replace all of the screws. Check and maintain the tightness of all

the fasteners.

WARNING: Do not over-tighten the switch housing screws.

Keep the machine clean especially at the handle tube and collar

so the handle tube will move freely through the collar. Inspect

the cord for cuts, gashes, or loose prongs; replace as needed.

Disassembly of this motor voids the warranty. Improper disas-

sembly and assembly of this motor can permanently damage the

field or rotor.

Picture #1

Picture #2

Picture #3

Switch

Trigger

Safety

Switch

Loading...

Loading...