CoolingSystem

Maintenance

CoolingSystemSafety

•Swallowingenginecoolantcancause

poisoning;keepoutofreachfromchildrenand

pets.

•Dischargeofhot,pressurizedcoolantortouching

ahotradiatorandsurroundingpartscancause

severeburns.

–Alwaysallowtheenginetocoolatleast15

minutesbeforeremovingtheradiatorcap.

–Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

CleaningtheRadiator

Screen

ServiceInterval:BeforeeachuseordailyCleanit

hourlyifconditionsareextremely

dustyanddirty.

Topreventthesystemfromoverheating,theradiator

screenandradiatormustbekeptclean.Checkand

cleanthescreenandradiatordailyor,ifnecessary,

hourly.Cleanthesecomponentsmorefrequentlyin

dusty,dirtyconditions.

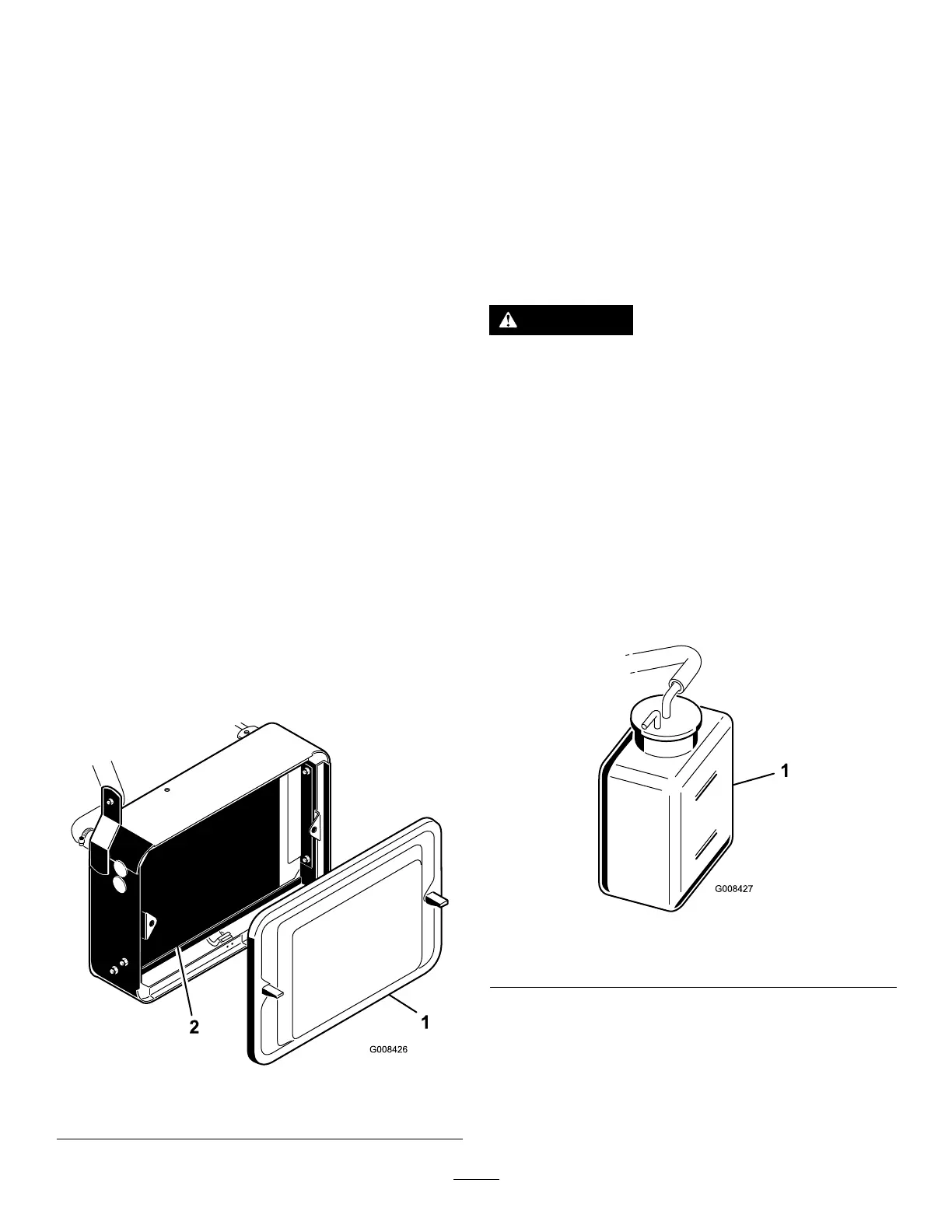

1.Removetheradiatorscreen(Figure43).

2.Workingfromthefansideoftheradiator,blow

outtheradiatorwithcompressedair.

g008426

Figure43

1.Radiatorscreen2.Radiator

3.Cleanthescreenandinstallit.

Checkingthe

Engine-CoolantLevel

Thecapacityofthecoolingsystemisapproximately

3.2L(3.3USqt).

Fillthecoolingsystemwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.Check

thelevelofthecoolantatthebeginningofeachday

beforestartingtheengine.

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeand

causeburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

1.Parkthemachineonalevelsurface.

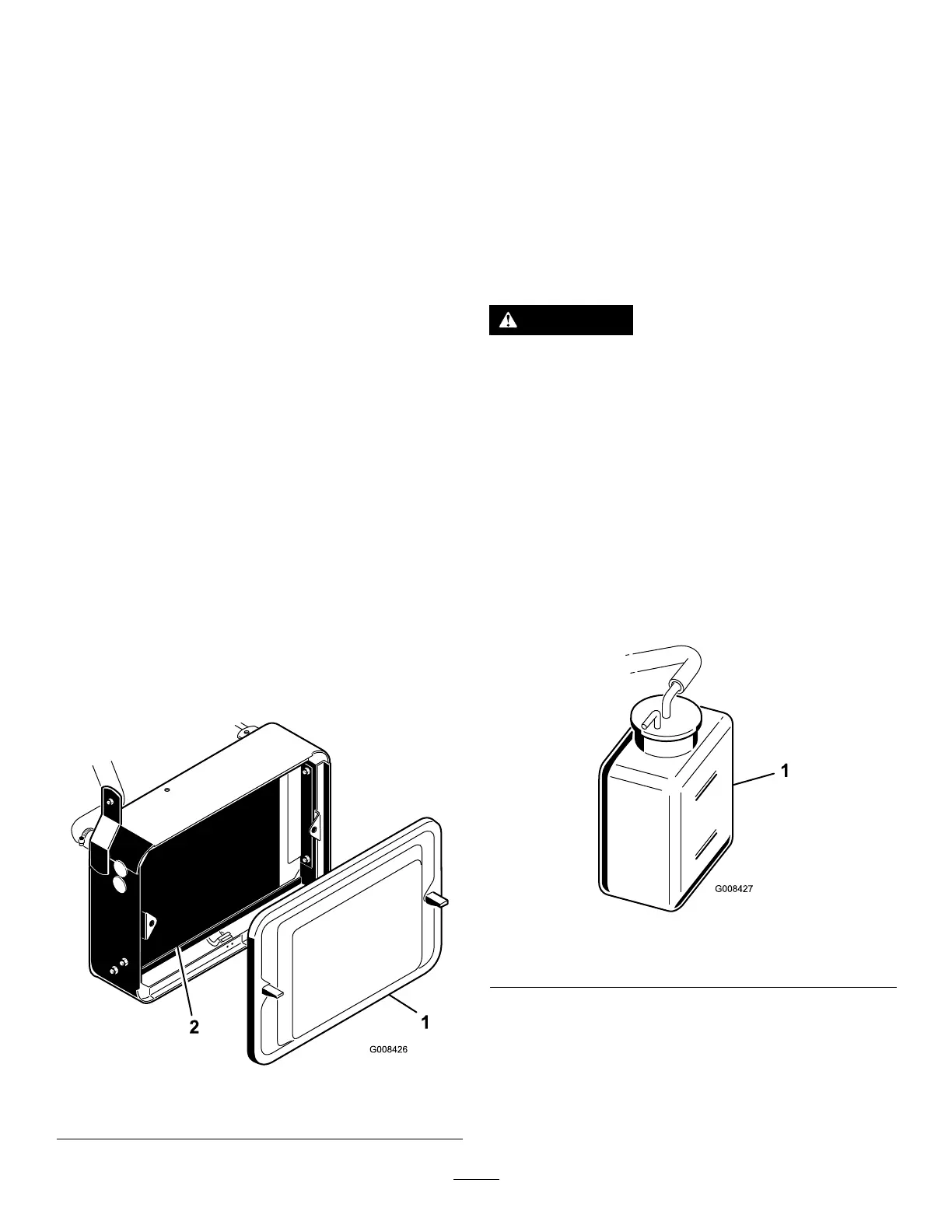

2.Checkthecoolantlevel(Figure44).

Itshouldbebetweenthelinesonthereserve

tankwhentheengineiscold.

g008427

Figure44

1.Reservetank

3.Ifthecoolantislow,removethereservetankcap

andadda50/50mixtureofwaterandpermanent

ethyleneglycolantifreeze.Donotoverll.

4.Installthereserve-tankcap.

41

Loading...

Loading...