DriveSystem

Maintenance

CheckingtheAirPressure

intheTires

ServiceInterval:Every50hours

Note:Thesemi-pneumaticcastertiresdonotneed

tobeinated.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Checkthepressureofthedrivetires.

3.Inatethedrivetiresto83to97kPa(12to14

psi).

CheckingtheWheelHub

Nuts

ServiceInterval:Yearly

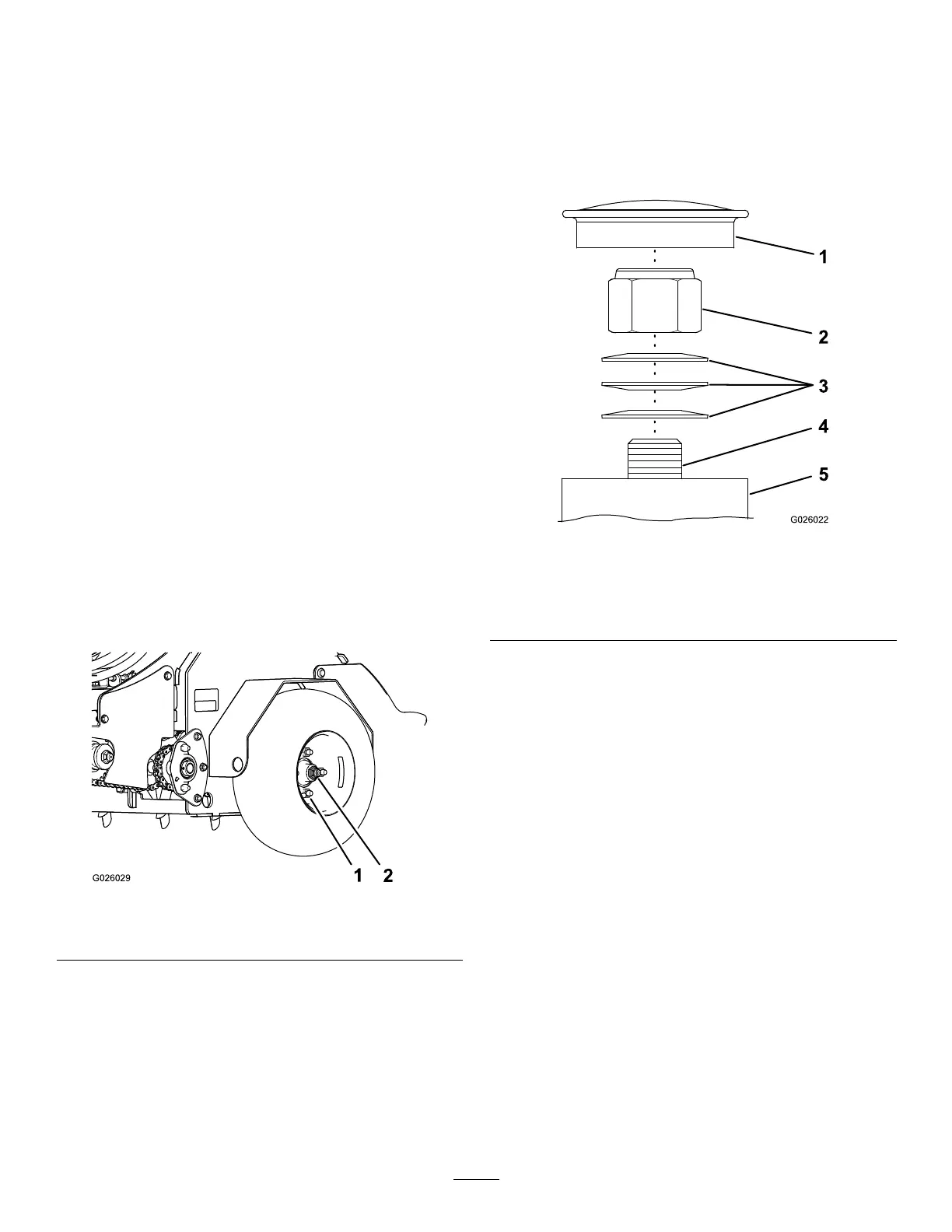

Torquethewheelhubnuts(Figure43)to285to350

N∙m(210to260ft-lb).

Note:Donotuseanti-seizecompoundonthewheel

hub.

g026029

Figure43

1.Lugnut2.Hubnut

CheckingtheTorqueofthe

WheelLugNuts

ServiceInterval:Yearly

Torquethewheellugnuts(Figure43)to122to129

N∙m(90to95ft-lb).

AdjustingtheCasterPivot

BearingsPre-Load

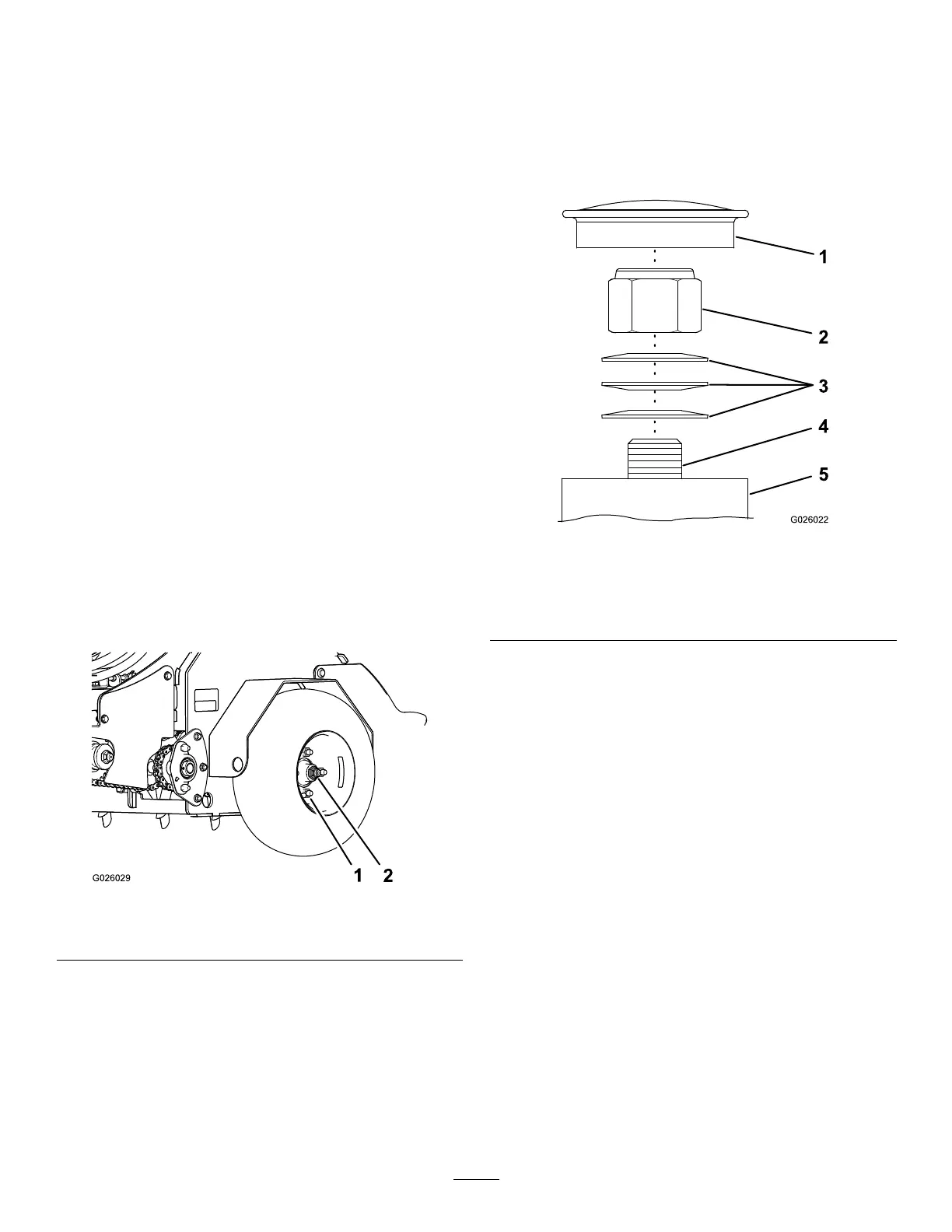

Note:Ifyoudisassemblethecasterpivotbearings,

ensurethatthespring-discwashersareinstalledas

showninFigure44.

1.Removedustcapfromcasterhub(Figure44).

g026022

Figure44

1.Dustcap

4.Spindle

2.Locknut

5.Casterhub

3.Spring-discwashers

2.Tightenthelocknutclockwiseuntilthe

spring-discwashersareat(Figure44).

3.Rotatethelocknutcounterclockwise1/4turn

(Figure44).

4.Installthedustcap(Figure44).

MaintainingtheChain

AdjustingtheJackshaft

Drive-ChainTension

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Lifttherearofthemachineandsupportitusing

jackstandsorequivalentsupport.

3.Checkthechainsonbothsidesofthemachine

forpropertension.

Note:Thechainsshouldmoveupanddown6

to12mm(1/4to1/2inch).

4.Ateachsideofthemachine,loosenthe3nuts

andboltsthatsecurethetransmissionmount

andtensionerplate,andthe2nutssecuringthe

41

Loading...

Loading...