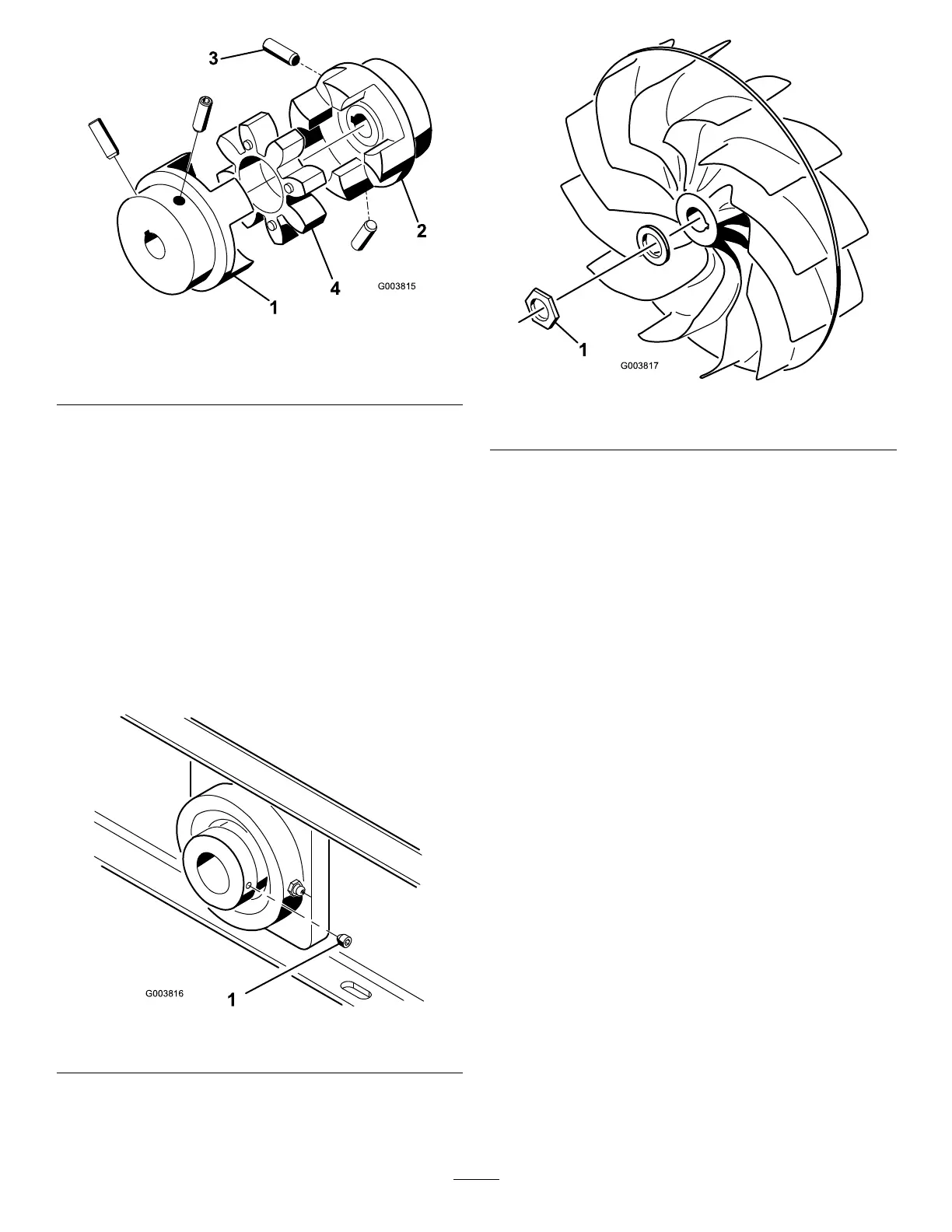

Figure14

1.Motorcoupler

3.Setscrew(2each)

2.Fancoupler

4.Couplerspider

3.Tightenthecapscrewsandthenutssecuringthe

mountingbracketstogetherandtotheblowerhousing.

4.Removethealignmenttoolandnishassembly.

TorquingFasteners

Ifthebloweriseverdisassembled,thefollowingfasteners

mustbetorquedasspecied.Also,applyLoctite242tothe

threadsbeforeinstalling.

•Thesetscrewssecuringthemotorandfanshaftcouplers

(Figure14)mustbetorquedto58to82in-lb.

•Thefanshaftbearingsetscrews(Figure15)mustbe

torquedto58to82in-lb.

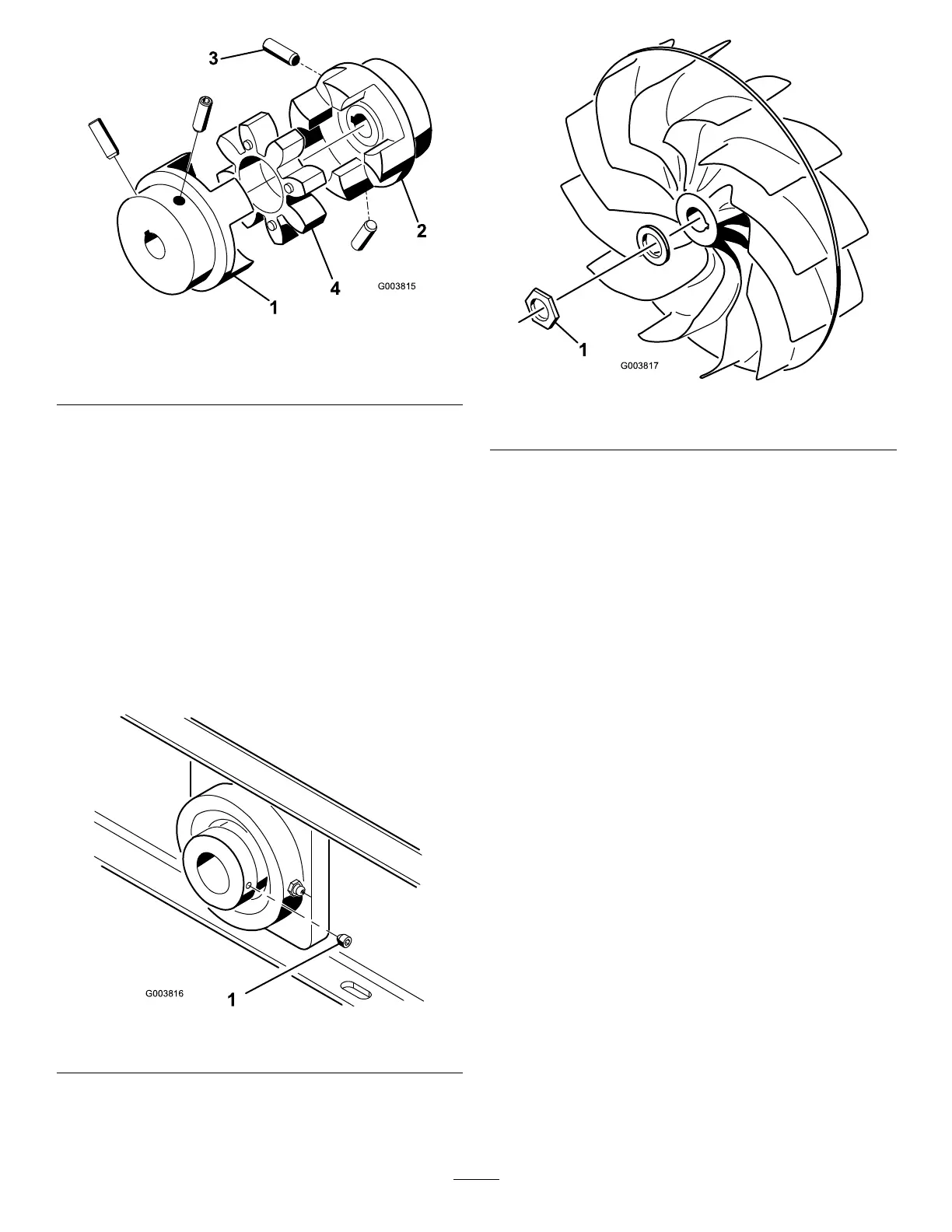

Figure15

1.Setscrew

•Thefanmountingnut(Figure16)mustbetorquedto

500ft-lb.

Figure16

1.Fanmountingnut

ServicingtheCastorArm

Bushings

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,the

bushingswillwear.Tocheckthebushings,movethecastor

forkbackandforthandfromsidetoside.Ifthecastor

spindleislooseinsidethebushings,thebushingsareworn

andmustbereplaced.

1.Raisethedebrisblowersothatthewheelsareoffofthe

oor.Blocktheblowersothatitcannotaccidentally

fall.

2.Removethetensioningcap,spacer,andthrustwasher

fromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.Allow

thethrustwasherandspacertoremainonthebottom

ofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

(Figure17).Also,drivetheotherbushingoutofthe

tube.Cleantheinsideofthetubestoremovedirt.

14

Loading...

Loading...