34

4. Remove the idler pulley and the worn belt (Fig. 42).

5. Install the new mower belt.

6. Install the idler pulley.

7. Engage the blade control (PTO) lever and check the belt

tension. Refer to Adjusting the Mower Belt Tension,

page 34.

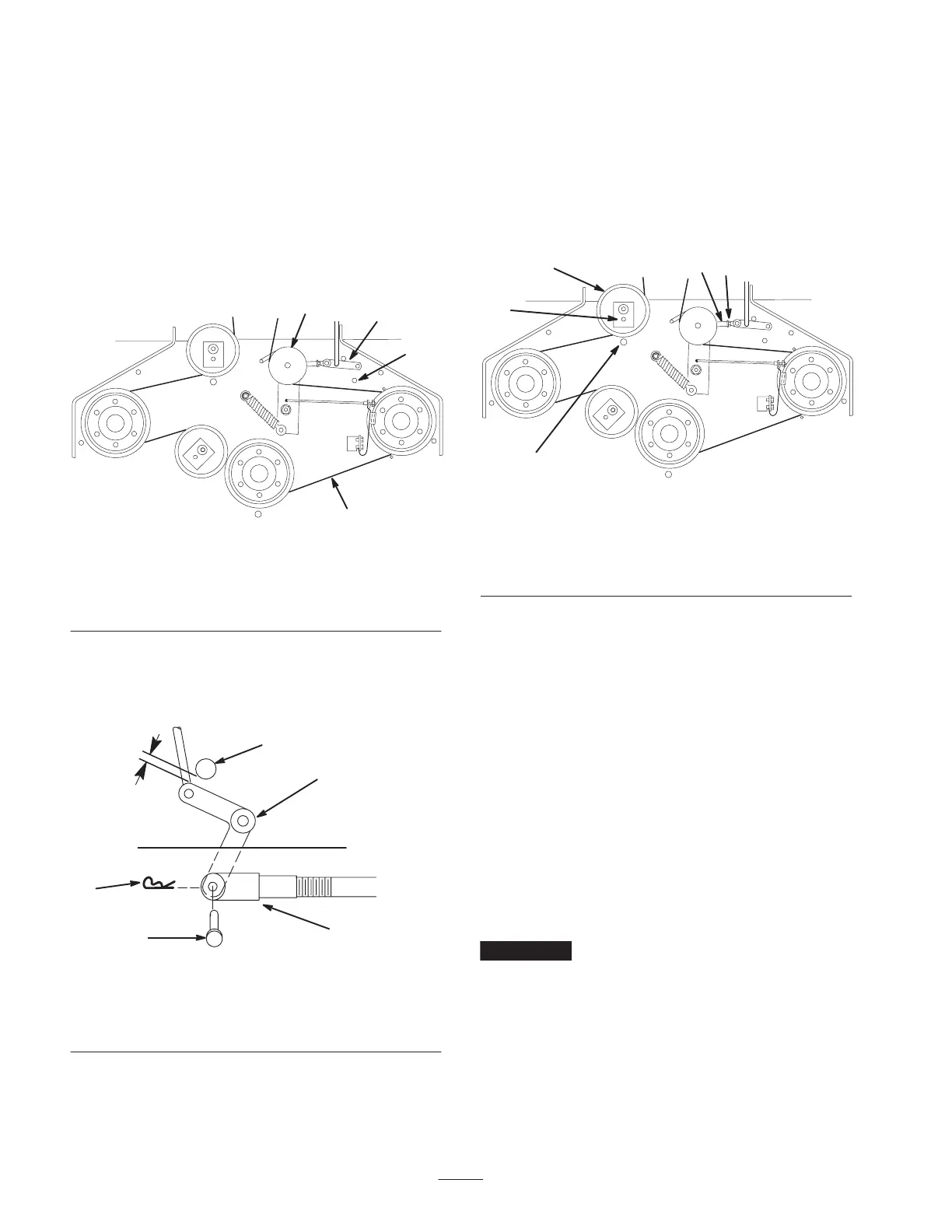

Note: The proper mower belt tension is 10–15 lbf. (44–67

N) with the belt deflected 1/2 in. (13 mm) halfway between

the pulleys (Fig. 43).

2

m–4731

3

4

1

Figure 43

1. Idler pulley

2. 1/2 in. (13 mm) deflection

here

3. Assist arm

4. Front stop

8. Engage the blade control (PTO) lever.

9. Check the clearance between the bell crank and the

transmission output shaft (Fig. 44).

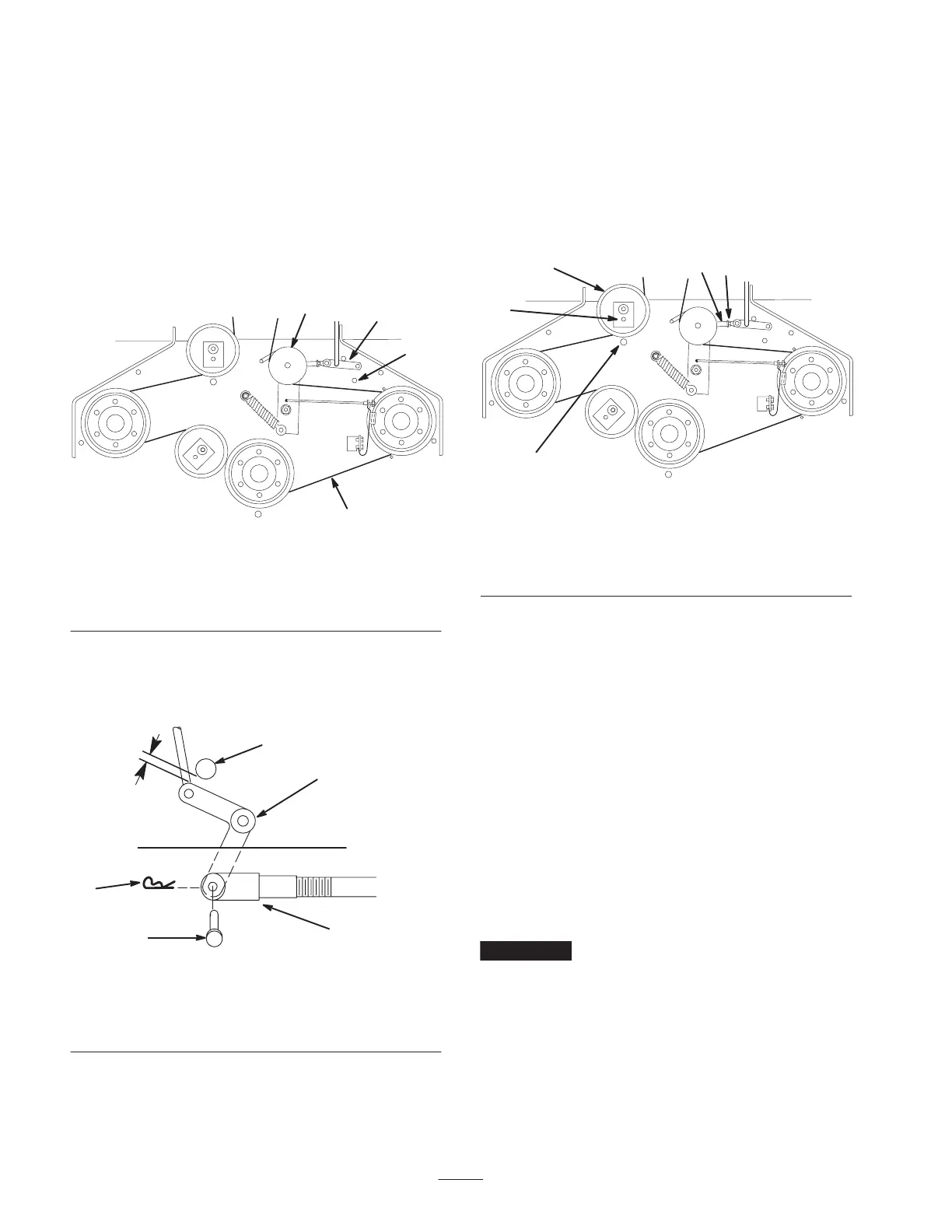

m–3860

1

4

5

6

2

3

Figure 44

1. 1/16–1/8 in. (2–3 mm)

2. Bell crank

3. Transmission output shaft

4. Hairpin cotter

5. Clevis pin

6. Clevis

Note: The clearance should be 1/16–1/8 in. (2–3 mm).

10. Remove the hairpin cotter and the clevis pin from the

bell crank.

11. Rotate the clevis clockwise on the rod to increase the

clearance; rotate it counterclockwise to decrease it

(Fig. 44).

12. Disengage the blade control (PTO) lever.

Note: If the assist arm does not contact the front stop on

the mower deck (Fig. 45), adjust the clevis to bring the

bell crank closer to the transmission output shaft

(Fig. 44).

m–4731

12

3

5

4

Figure 45

1. Locknut

2. Turnbuckle

3. Rear idler pulley

4. Front position for idler

pulley

5. Belt guide

13. Check the belt guide under the engine frame for the

proper adjustment (Fig. 42).

Note: The distance between the belt guide and the

mower belt should be 1-1/4 in. (32 mm) when you

engage the mower belt. Adjust the mower belt as

necessary. The disengaged belt should not drag or fall

off the pulley when the guides are properly adjusted.

Adjusting the Mower Belt

Tension

Service Interval/Specification

Check the belt tension after the first 8 operating hours and

every 25 operating hours thereafter. Check the belt tension

after every 50 operating hours.

Important The belt must be tight enough to not slip

during heavy loads while cutting grass. Over tensioning the

belt will reduce the bearing life of the belt and the spindle.

1. Disengage the blade control (PTO) lever and set the

parking brakes.

2. Stop the engine and wait for all moving parts to stop

before leaving the operating position.

3. Loosen the locknut on the turnbuckle (Fig. 45).

Loading...

Loading...