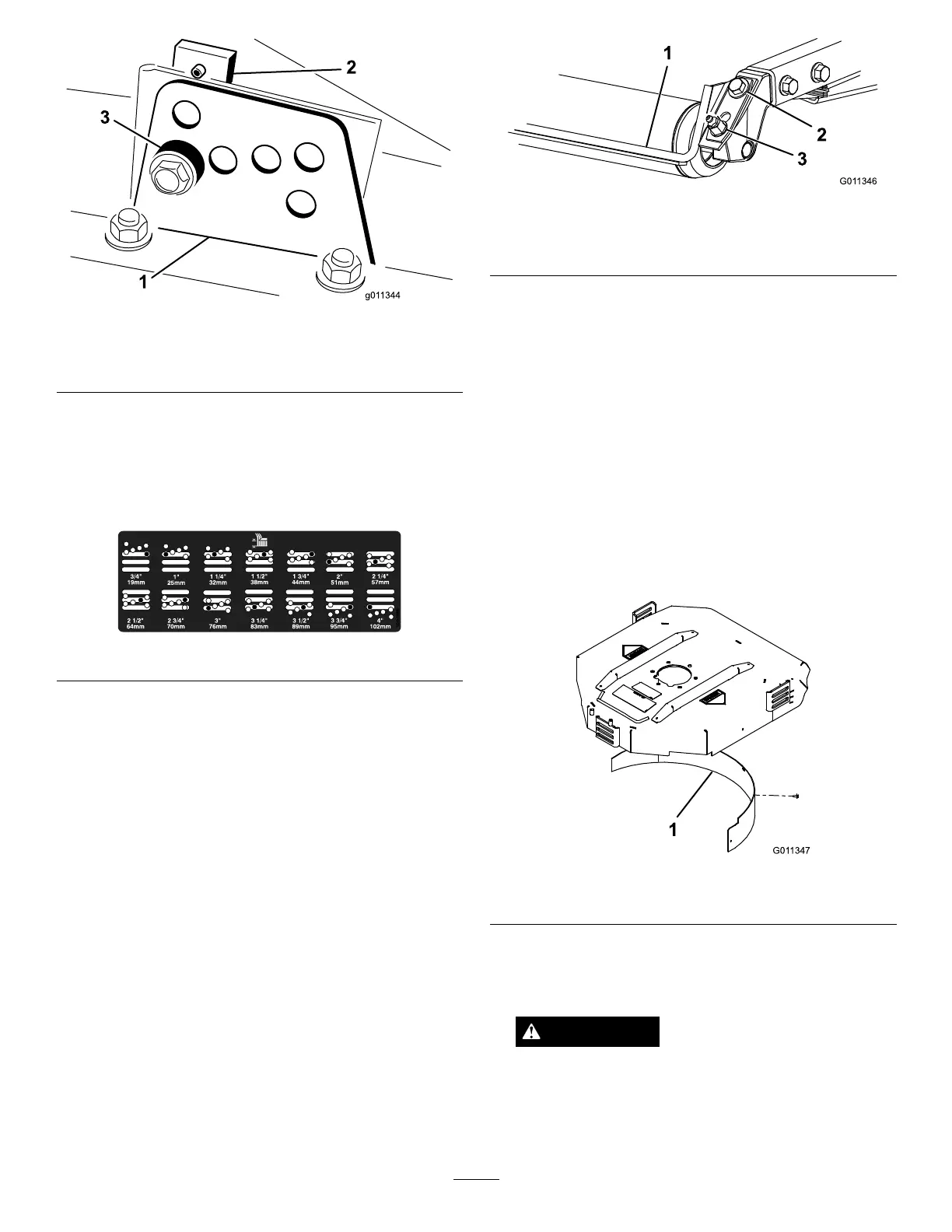

Figure3

1.Heightofcutbracket3.Spacer

2.Heightofcutplate

4.Whilesupportingthechamber,removethespacer

(

Figure3).

5.Movethechambertothedesiredheight-of-cutand

installaspacerintothedesignatedheight-of-cuthole

andslot(Figure4).

Figure4

6.Positionthetappedplateinlinewiththespacer.

7.Installtheboltngertight.

8.Repeatsteps4–7foreachsideadjustment.

9.Tightenallthreeboltsto30ft-lb(41N-m).Always

tightenthefrontboltrst.

Note:Adjustmentsofmorethan1-1/2inches

(3.8cm)mayrequiretemporaryassemblytoan

intermediateheighttopreventbinding(e.g.changing

from1.25to2.75inch(3.1to7cm)height-of-cut).

AdjustingtheRollerScraper

(Optional)

Theoptionalrearrollerscraperisdesignedtoworkbest

whenthereisanevengapof0.020–0.040inch(0.5to1

mm)betweenthescraperandroller.

1.Loosenthegreasettingandmountingscrew

(

Figure5).

Figure5

1.Rollerspacer

3.Greasetting

2.Mountingscrew

2.Slidethescraperupordownuntilagapof0.020to

0.040inch(0.5to1mm)isachievedbetweenthe

rodandtheroller.

3.Securethegreasettingandscrewto30ft-lb(41

N-m)inanalternatingsequence.

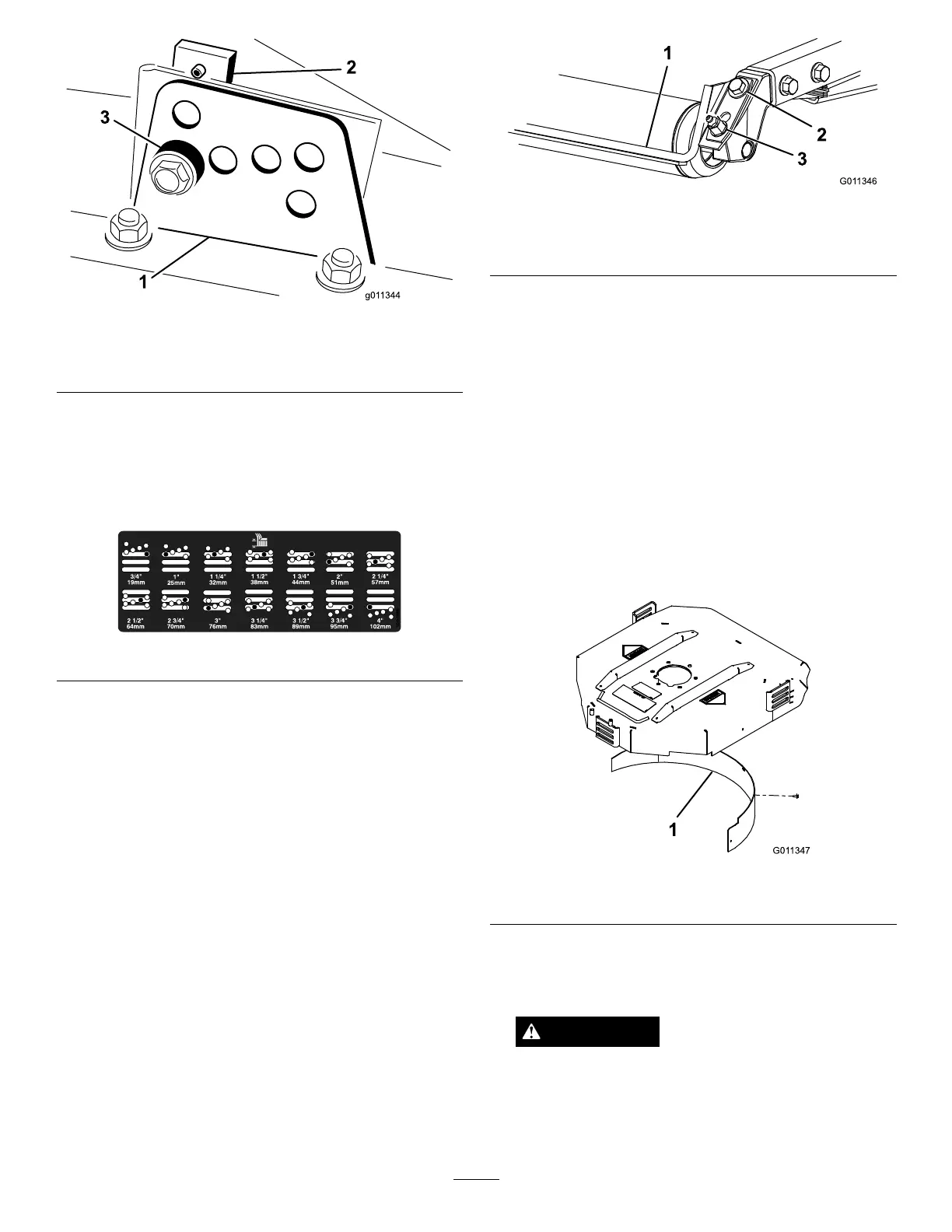

InstallingtheMulchingBafe

(Optional)

1.Thoroughlycleandebrisfromthemountingholes

ontherearwallandleftsidewallofthechamber.

2.Installthemulchingbafeintherearopeningand

secureitwith5angeheadbolts(Figure6).

Figure6

1.Mulchingbafe

3.Verifythatmulchingbafedoesnotinterferewith

thetipofthebladeanddoesnotprotrudeinsidethe

surfaceoftherearchamberwall.

WARNING

Donotusethehighliftbladewiththemulching

bafe.Thebladecouldbreak,resultingin

personalinjuryordeath.

5

Loading...

Loading...