Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Beforeeachuseordaily

•Checkthebladestoppingtime.

Every50hours

•Greasethebearings

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

UsingtheCuttingDeckService

Latch(Groundsmaster3500-D

and3500-Gonly)

Whenservicingthecuttingdecks,usetheservicelatch

topreventinjury.

1.Centerthecuttingdecksidewinderwiththetraction

unit.

2.Raisethecuttingdeckstothetransportposition.

3.Settheparkingbrakeandturnoffthemachine.

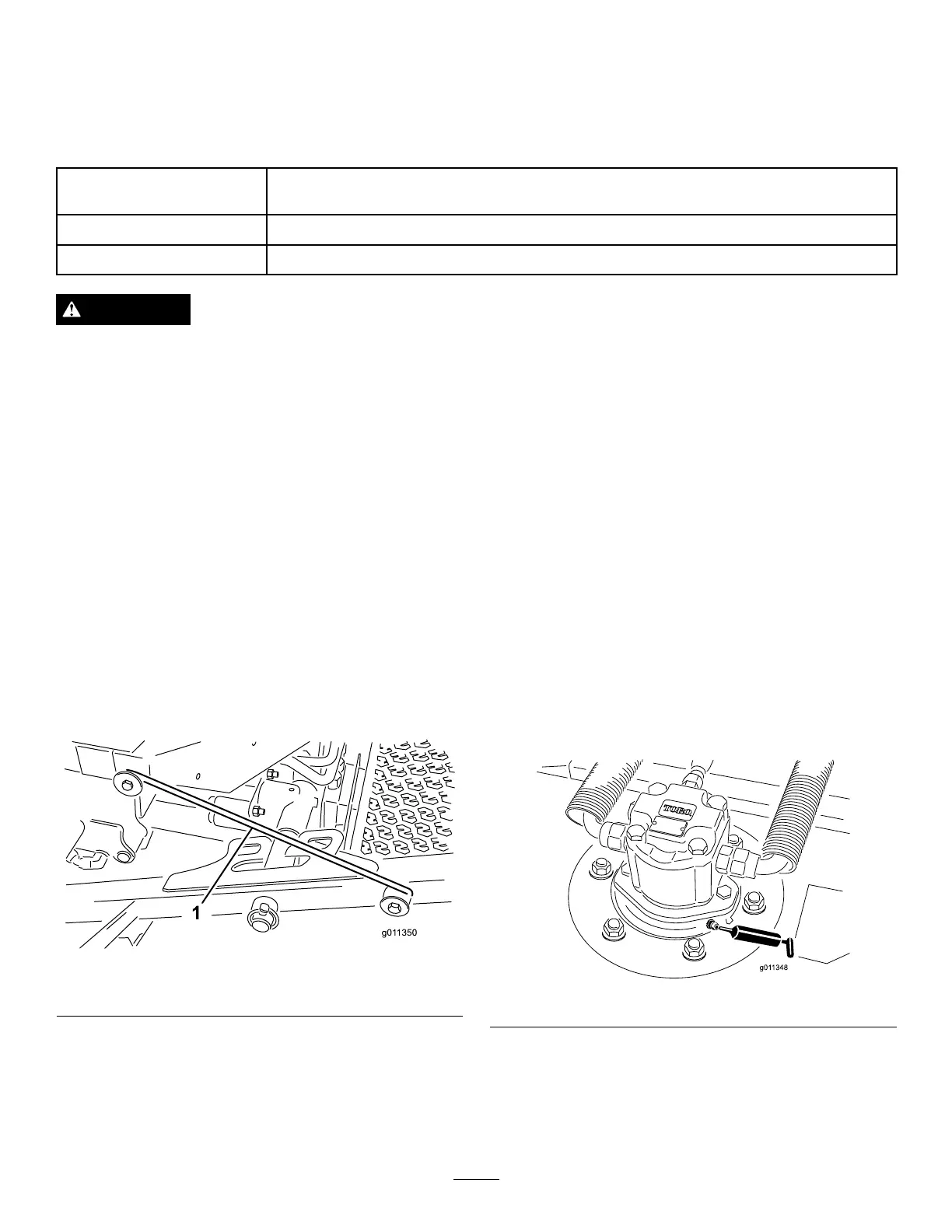

4.Releasethelatchrod(Figure7)fromfrontcarrier

frameretainer.

Figure7

1.Servicelatchhook

5.Lifttheoutsideofthefrontcuttingdecksandplace

thelatchovertheframepinmountedonthefrontof

theoperator'splatform(Figure7).

6.Sitontheoperatorseatandstartthetractionunit.

7.Lowerthecuttingdeckstothemowposition.

8.Turnoffthemachineandremovethekey.

9.Reversethisproceduretounlatchthecuttingdecks.

GreasingtheBearings

ServiceInterval:Every50hours

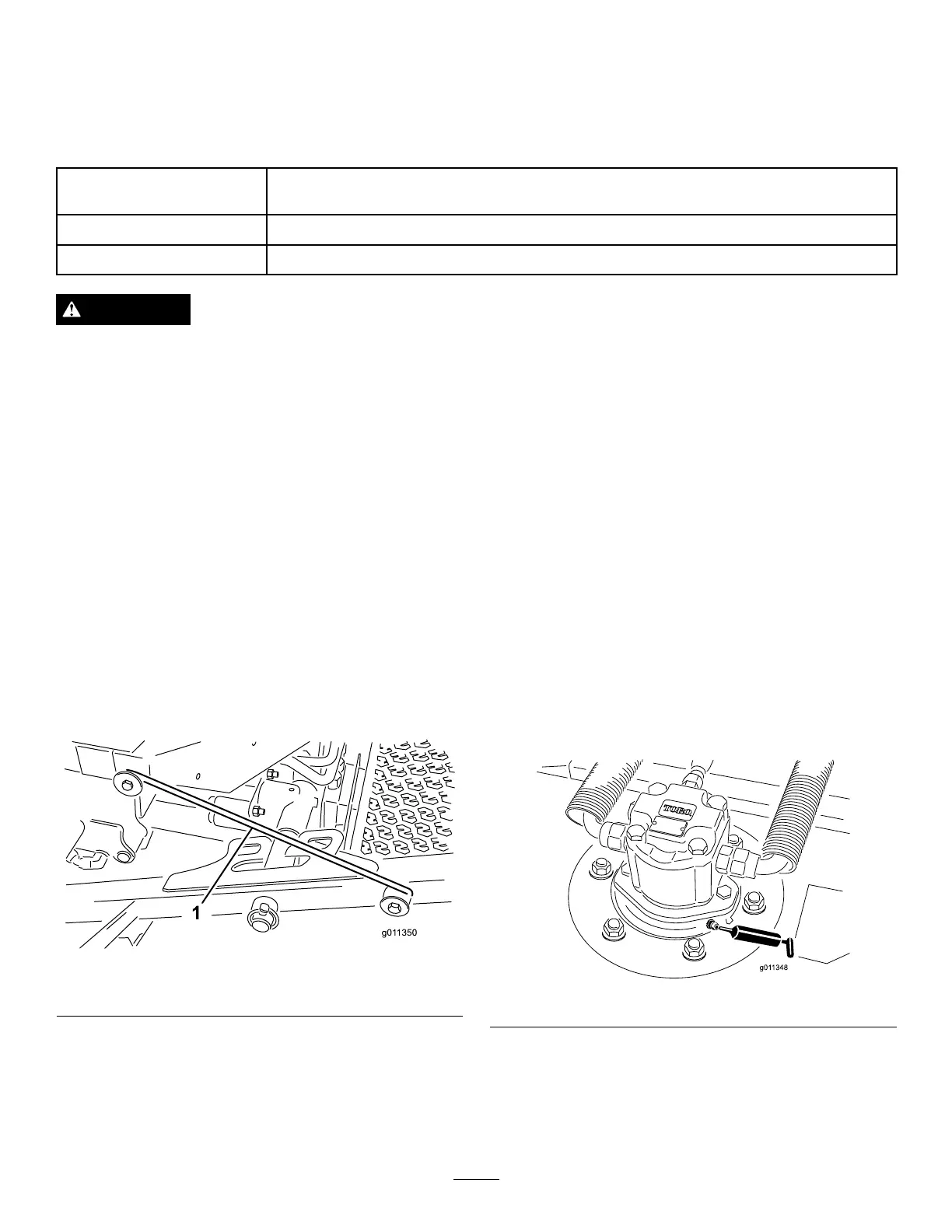

Eachcuttingdeckhastwogreasettingsperspindle.

Eitherttingcanbeused,whicheverismoreaccessible.

Ifthemachineisoperatedundernormalconditions,

lubricatebladespindlebearings(

Figure8)withNo.2

generalpurposelithiumbasegreaseormolybdenum

basegrease,afterevery50hoursofoperation.Pump

greaseintothettinguntilasmallamountappearsat

bottomofthespindlehousing(underthedeck).

Figure8

Eachcuttingdeckhastwogreasettingsperrearroller.

Ifthemachineisoperatedundernormalconditions,

lubricaterearrollerbearings(

Figure9)withNo.2

generalpurposelithiumbasegreaseormolybdenum

basegrease,afterevery50hoursofoperation.

9

Loading...

Loading...