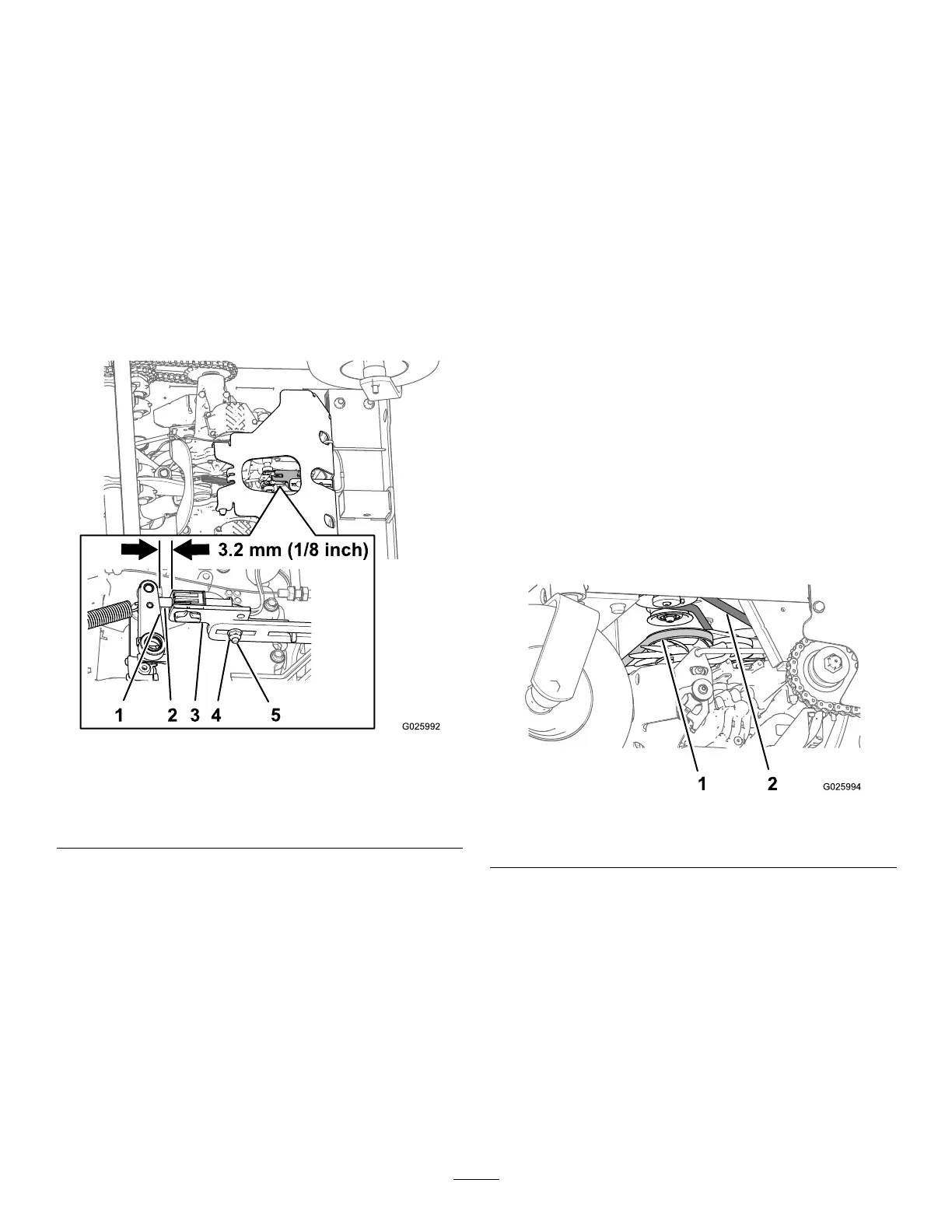

AdjustingtheBrakeSwitch

1.Parkthemachineonalevelsurface.

2.Shutofftheengineandwaitforallmovingparts

tostop.

3.Priortheadjustingthebrakeswitchensurethat

theparkingbrakeisproperlyadjusted;referto

AdjustingtheParkingBrake(page43).

4.Engagetheparkingbrake.

5.Checkthedistancebetweentheparking

brake-switchbrackettothebrakearmofthe

transmission(Figure49).

Note:Thedistanceshouldbe3.2mm(1/8

inch).

g025992

Figure49

1.Brakearm(transmission)

4.Locknut

2.Plunger(brakeswitch)5.Carriagebolt

3.Brake-switchbracket

6.Ifadjustmentisrequired,preformthefollowing:

A.Loosenthelocknutandcarriagebolt

securingtheparkingbrakeswitchbracket

(Figure49).

B.Adjustthepositionofthebrake-switch

bracketuntilthegap(Figure49)between

theswitchbracketandthebrakearmis3.2

mm(1/8inch)

C.Tightenthelocknutandcarriagebolt(Figure

49)securingthebrake-switchbracketto

1017to1243N∙cm(90to110in-lb).

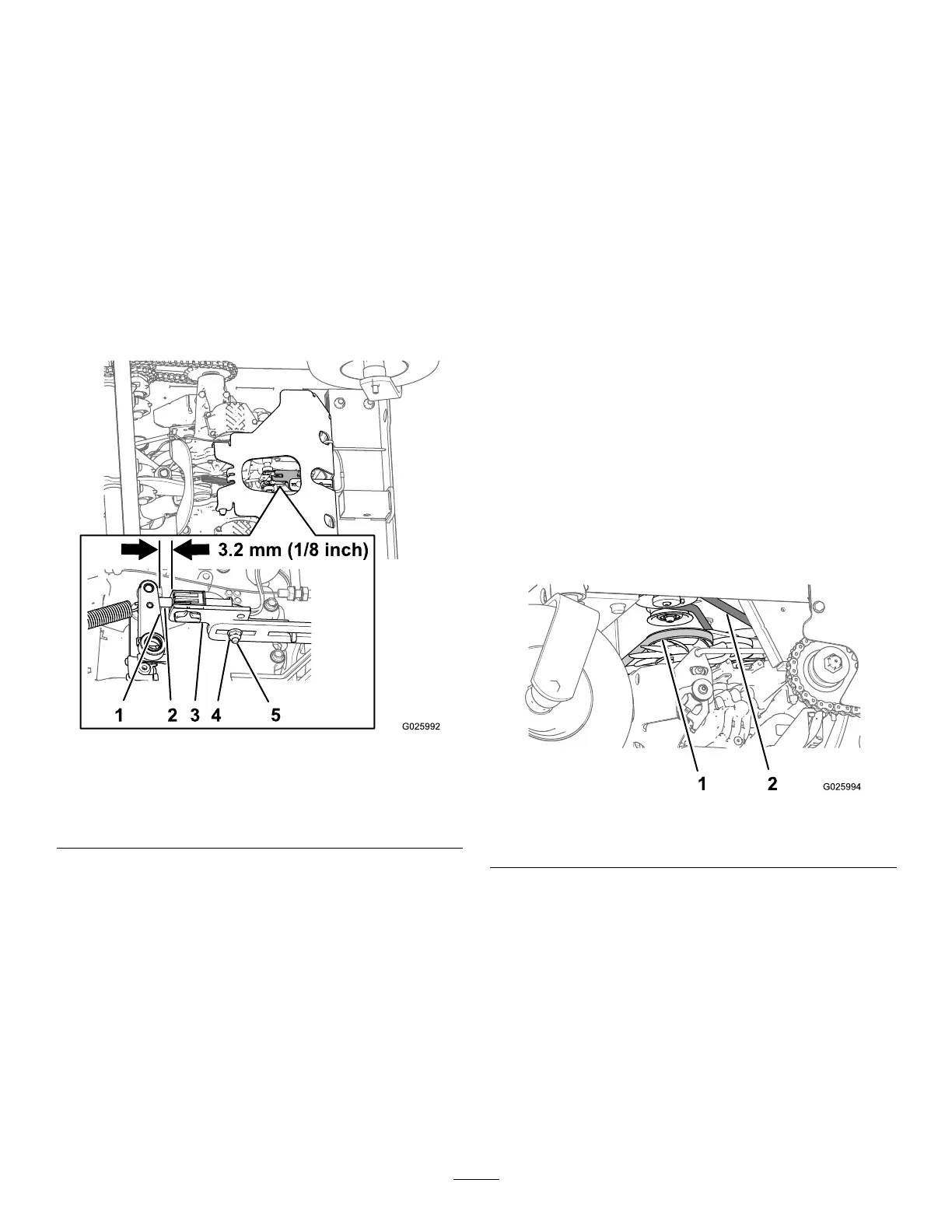

BeltMaintenance

CheckingtheCondition

andTensionoftheBelts

ServiceInterval:Every50hours

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Raisethemachineandsupportitwithjack

standswitha460kg(1,015lb)capacity.

3.Checktheauxiliarypump-drivebeltcondition

andtension(Figure50).

Note:Thebeltshoulddeect1.3cm(1/2inch)

when1.4kg(3lb)offorceisappliedtothebelt

midwaybetweentheauxiliarypumpandengine

pulleys.Ifthebelttensionistoohighortoolow,

refertoAdjustingtheAuxiliaryPump-DriveBelt

(page44).

4.Checkconditionofthetransmission-drivebelt

(Figure50).

Note:Thetransmissionbelthasa

automatic-springtensioner.

g025994

Figure50

1.Transmission-drivebelt2.Auxiliarypump-drivebelt

AdjustingtheAuxiliary

Pump-DriveBelt

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Loosenthelocknut(3/8inch)thatsecuresthe

auxiliarypump-idlerpulleytothechassisofthe

machine.

44

Loading...

Loading...