16

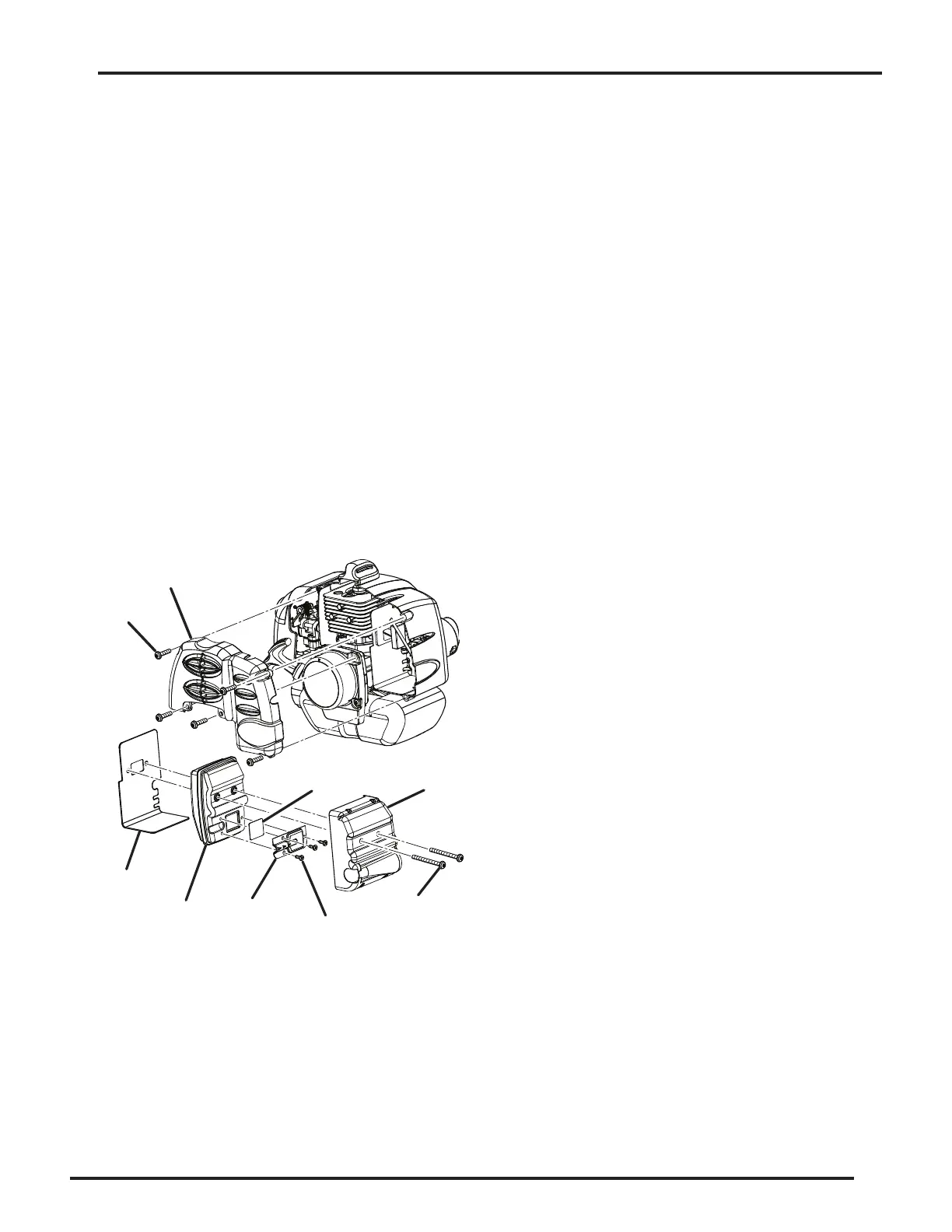

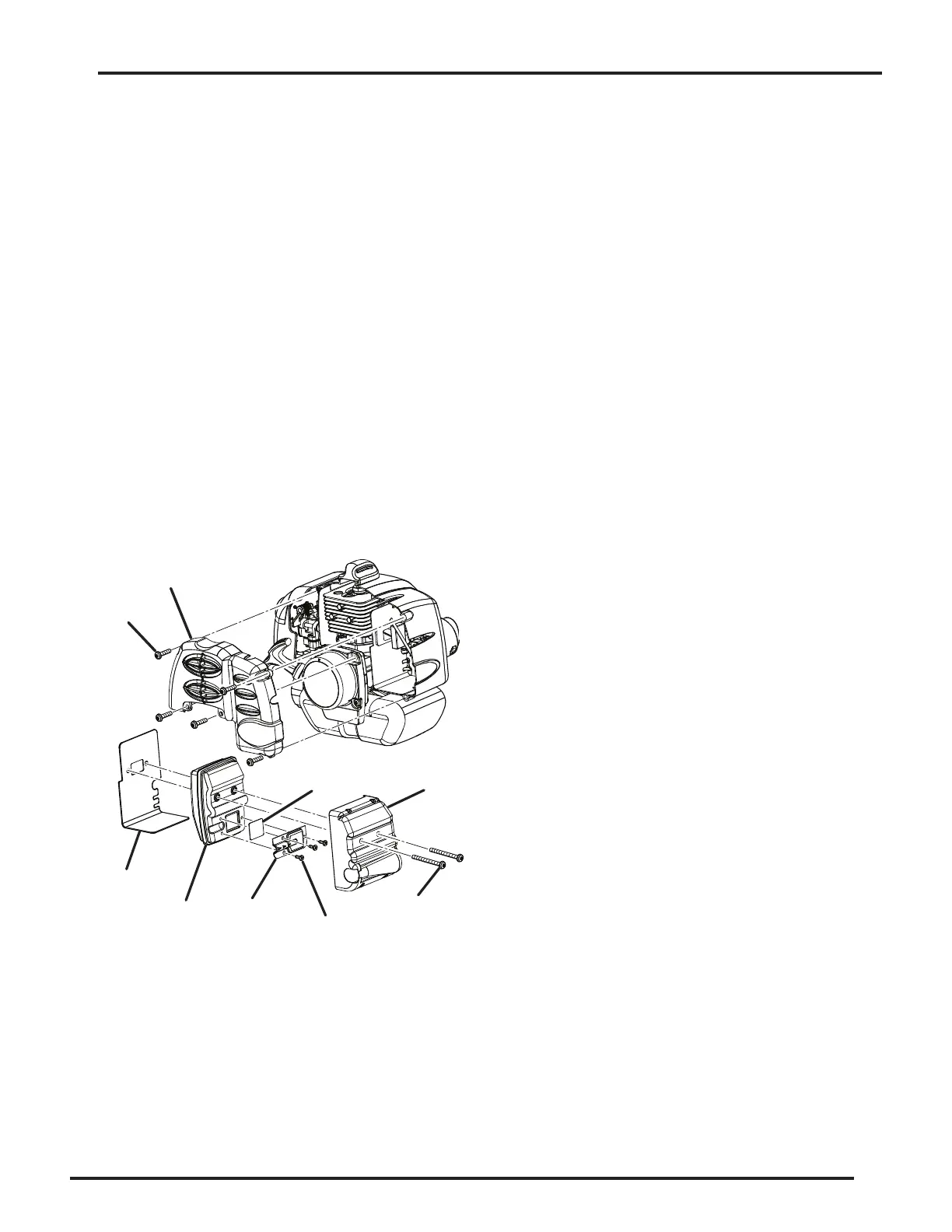

Figure 9

Maintenance

7. Rinse the air lter and let it dry completely.

8. Work two drops of oil into the air lter.

9. Replace the air lter (ts only one way).

10. Replace the air lter cover.

11. Tighten the air lter cover by turning the knob clock-

wise.

12. Replace the spark plug boot.

NOTE: Replace the air lter as indicated by the mainte-

nance schedule.

Replacing the Spark Arrestor

See Figure 9.

NOTE: Depending on the type of fuel used, the type and

amount of oil used, and/or your operating conditions, the

exhaust port and mufer may become blocked with carbon

deposits. If you notice a power loss with your gas powered

tool, you may need to remove these deposits to restore

performance. We highly recommended that only qualied

service technicians perform this service.

The spark arrester may need to be replaced after repeated

use. If replacement is necessary, use Toro part number

000998216.

Spark

Arrester

Plate

Muffler

Cover

Muffler

Gasket

Screw(s)

Screw(s)

Cover

Screw(s)

Muffler

To replace the spark arrester:

1. Remove the ve screws that hold the cover.

NOTE: Removing these screws requires the use of a

T20 and T25 torx screwdriver.

2. Remove the cover.

3. Remove the two screws holding the mufer assembly

in place.

4. Remove the mufer assembly and mufer gasket. It

may be necessary to work the mufer assembly free

from the mufer gasket.

5. Separate the mufer cover from the mufer.

6. Remove the three screws that hold the plates on the

mufer.

7. Remove the spark arrester.

8. Replace the old spark arrester with the new one.

9. Reassemble the mufer by reinstalling the plates and

tightening the three screws (torque to 18 in.lb. mini-

mum, 22 in.lb. maximum).

10. Reassemble the mufer and mufer cover and attach to

the mufer gasket with the two screws.

11. Reinsert the mufer assembly and tighten two screws

to engine (torque to 60 in.lb minimum, 80 in.lb. maxi-

mum).

12. Reinstall the cover on the tool and fasten with the ve

screws (torque to 16 in.lb. minimum, 22 in.lb. maximum).

NOTE: Do not overtighten screws.

Maintenance

Loading...

Loading...