23

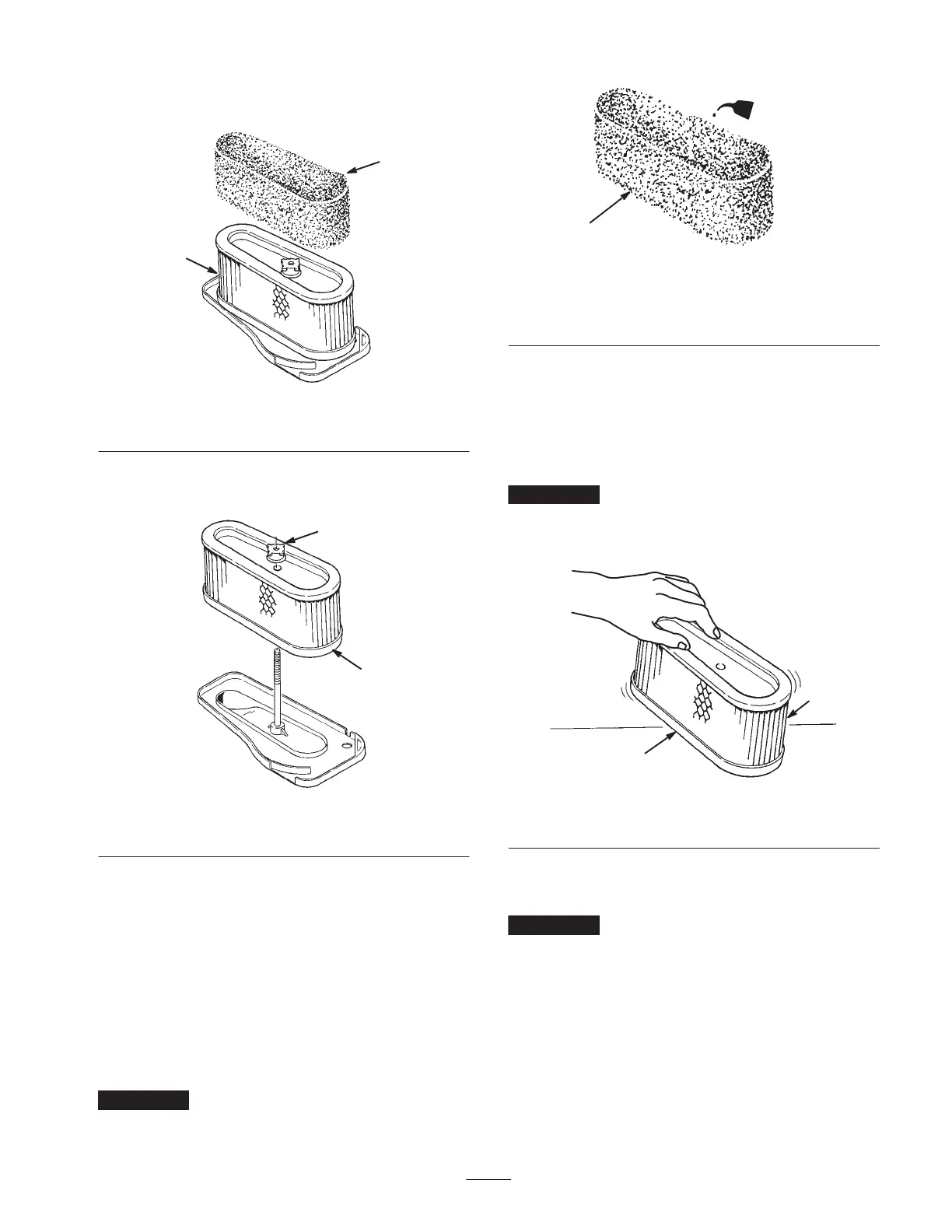

4. Carefully slide the foam element off of the paper

element (Fig. 23).

1

2

1864

Figure 23

1. Foam element 2. Paper element

5. Unscrew the rubber nut and remove the paper element

(Fig. 24).

2

1

1865

Figure 24

1. Rubber nut 2. Paper element

Cleaning the Foam and Paper Elements

1. Foam Element

A. Wash the foam element in liquid soap and warm

water. When the element is clean, rinse it

thoroughly.

B. Dry the element by squeezing it in a clean cloth.

C. Put one or two ounces of oil on the element

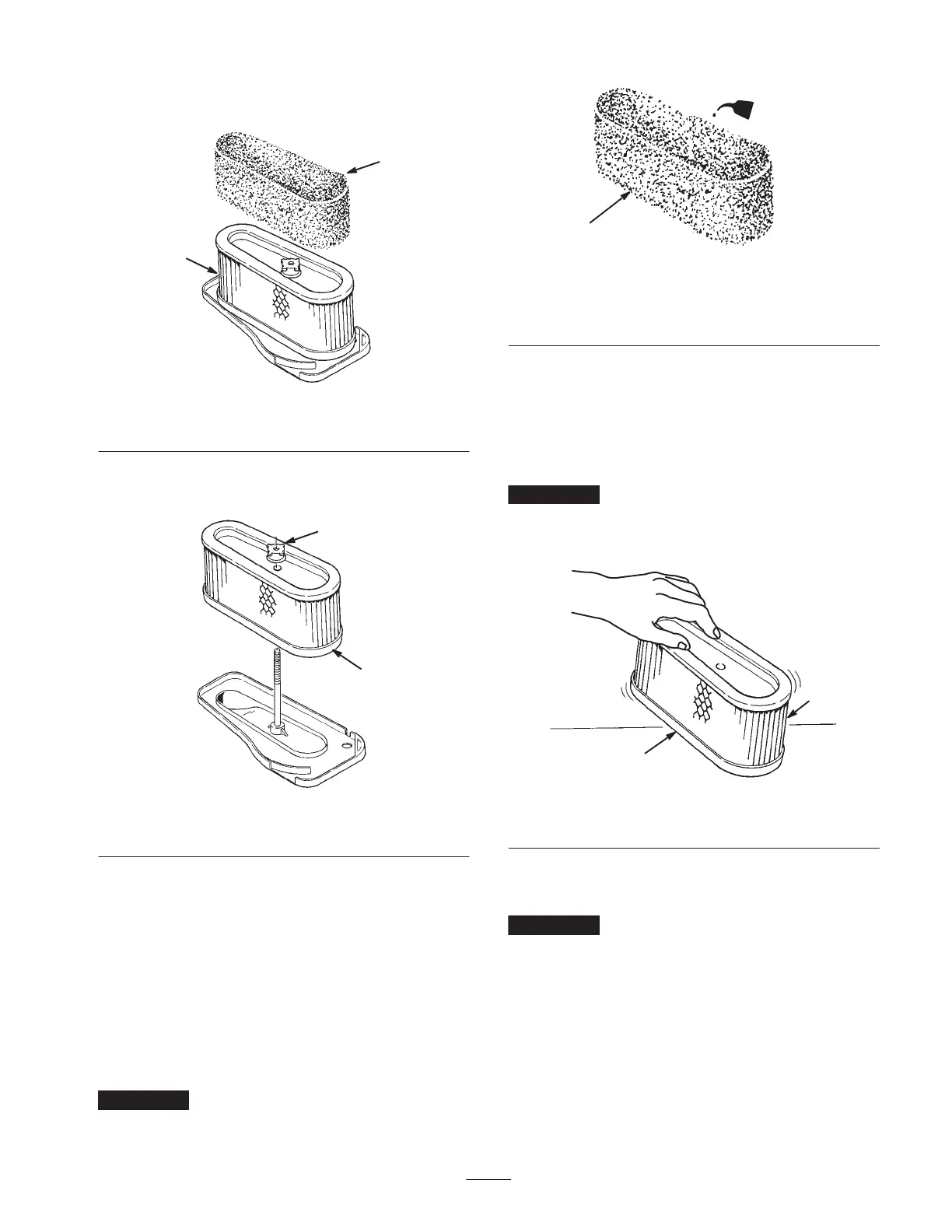

(Fig. 25). Squeeze the element to distribute the oil.

Important Replace the foam element if it is torn or

worn.

1

2

1866

Figure 25

1. Foam element 2. Oil

2. Paper Element

A. Lightly tap the element on a flat surface to remove

dust and dirt (Fig. 26).

B. Inspect the element for tears, an oily film, and

damage to the rubber seal.

Important Never clean the paper element with

pressurized air or liquids, such as solvent, gas, or kerosene.

Replace the paper element if it is damaged or cannot be

cleaned thoroughly.

1

2

1867

Figure 26

1. Paper element 2. Rubber seal

Installing the Foam and Paper Elements

Important To prevent engine damage, always operate

the engine with the complete foam and paper air cleaner

assembly installed.

1. Carefully slide the foam element onto the paper air

cleaner element (Fig. 23).

2. Slide the air cleaner assembly onto the long rod. Screw

the rubber nut finger-tight against the air cleaner

(Fig. 24).

Note: Make sure that the rubber seal is flat against the air

cleaner base.

Loading...

Loading...