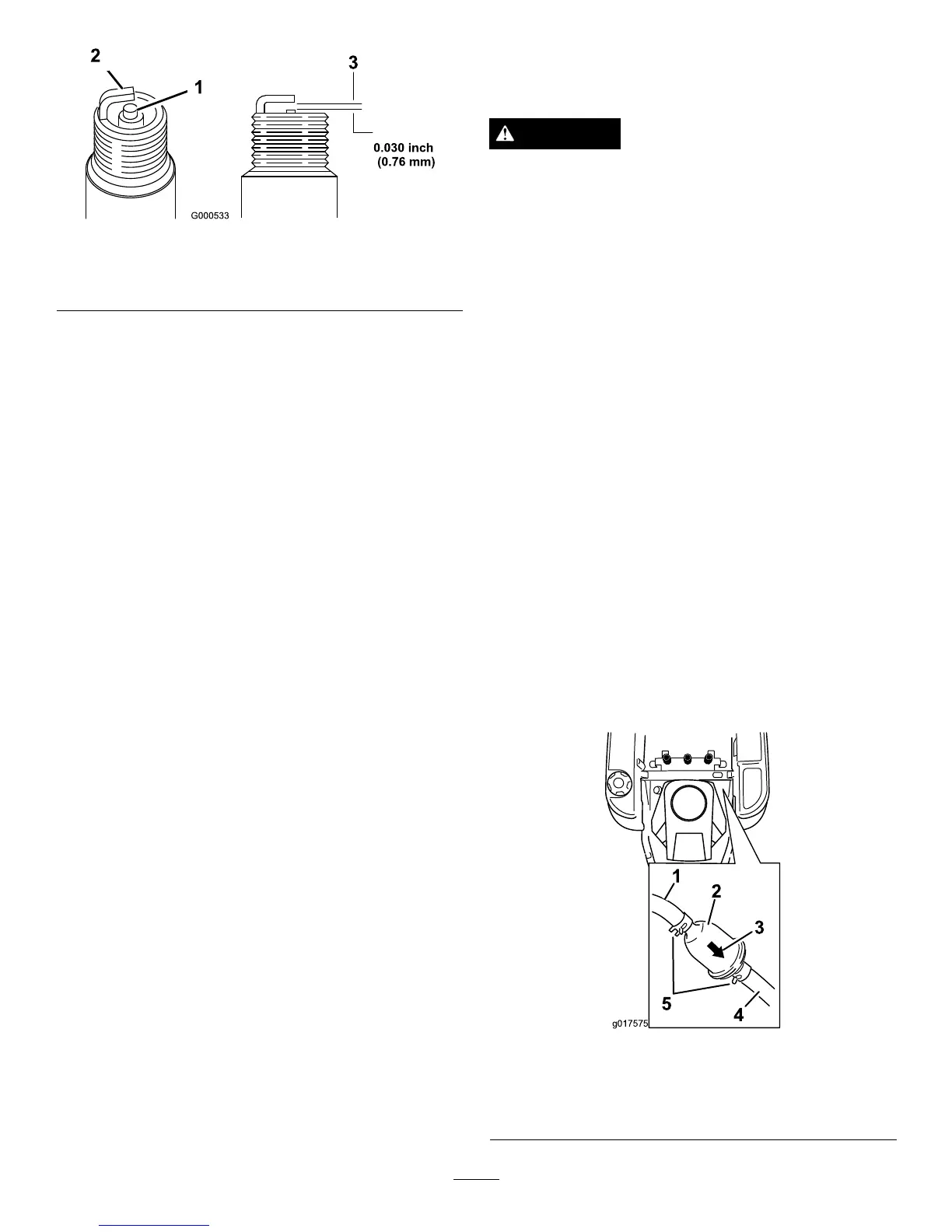

Figure32

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

InstallingtheSparkPlug

1.Installthesparkplug.Makesurethattheairgapis

setcorrectly.

2.Tightenthesparkplugto18-22ft-lb(25-29N-m).

3.Pushthewireontothesparkplug(

Figure31).

CleaningtheBlowerHousing

ServiceInterval:Beforeeachuseordaily—Checkair

intakeandcoolingareas,cleanas

necessary.

Every100hours—Cleantheblower

housing(moreoftenunderextremely

dusty,dirtyconditions).

Toensurepropercooling,makesurethegrassscreen,

coolingns,andotherexternalsurfacesoftheengine

arekeptcleanatalltimes.

Cleanthecoolingnsandexternalsurfacesasnecessary.

Makesurethecoolingshroudsarereinstalled.

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,willcauseenginedamage

duetooverheating.

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuelrelatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheIn-lineFuel

Filter

ServiceInterval:Every100hours—Replacethein-line

fuellter

Neverinstalladirtylterifitisremovedfromthefuel

line.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

parkposition,stoptheengine,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

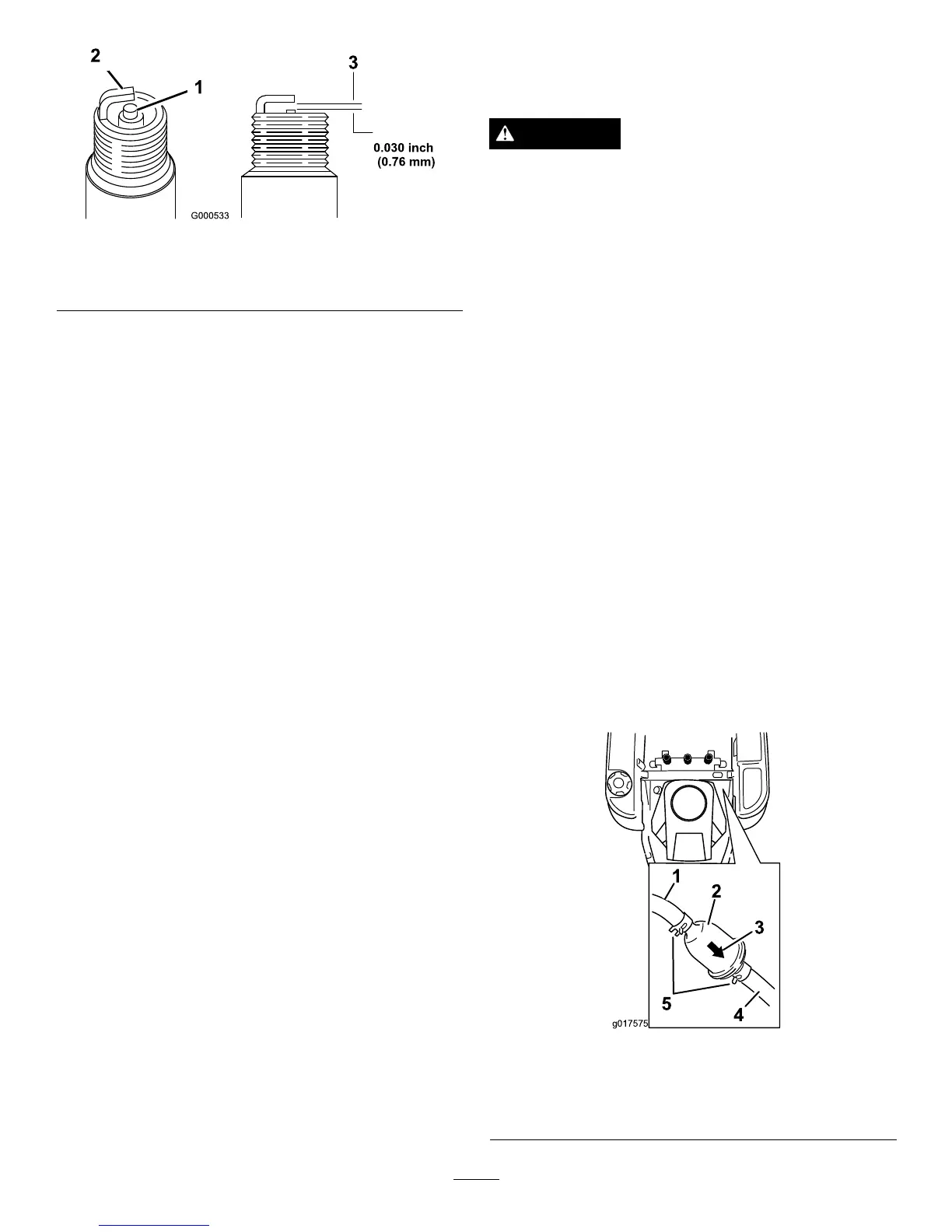

3.Locatethefuellteronthesideoftheengineas

shownin

Figure33.

Loading...

Loading...