FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Yearly(whichever

comesrst)(moreoftenunderdusty,

dirtyconditions).

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Allowthemachinetocooldown.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

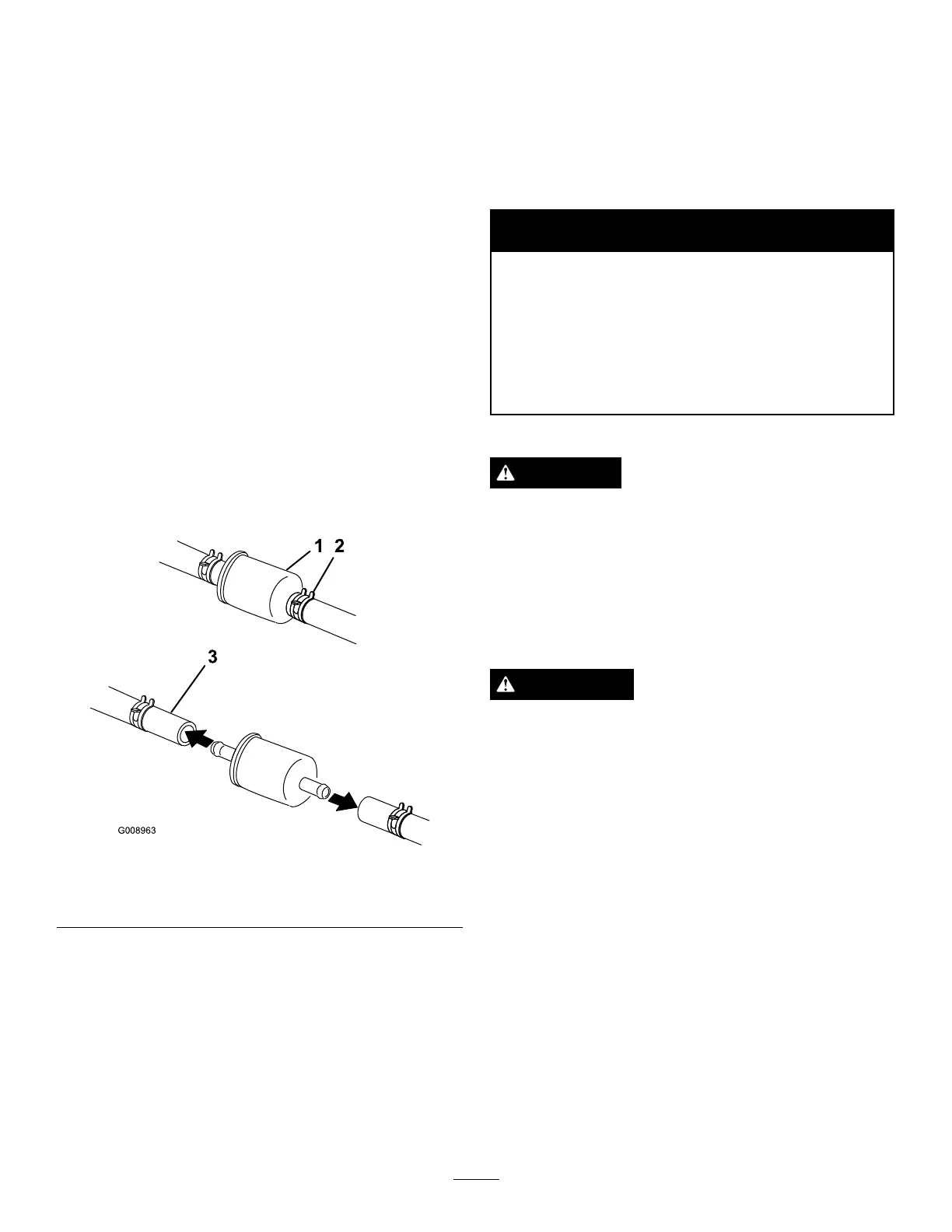

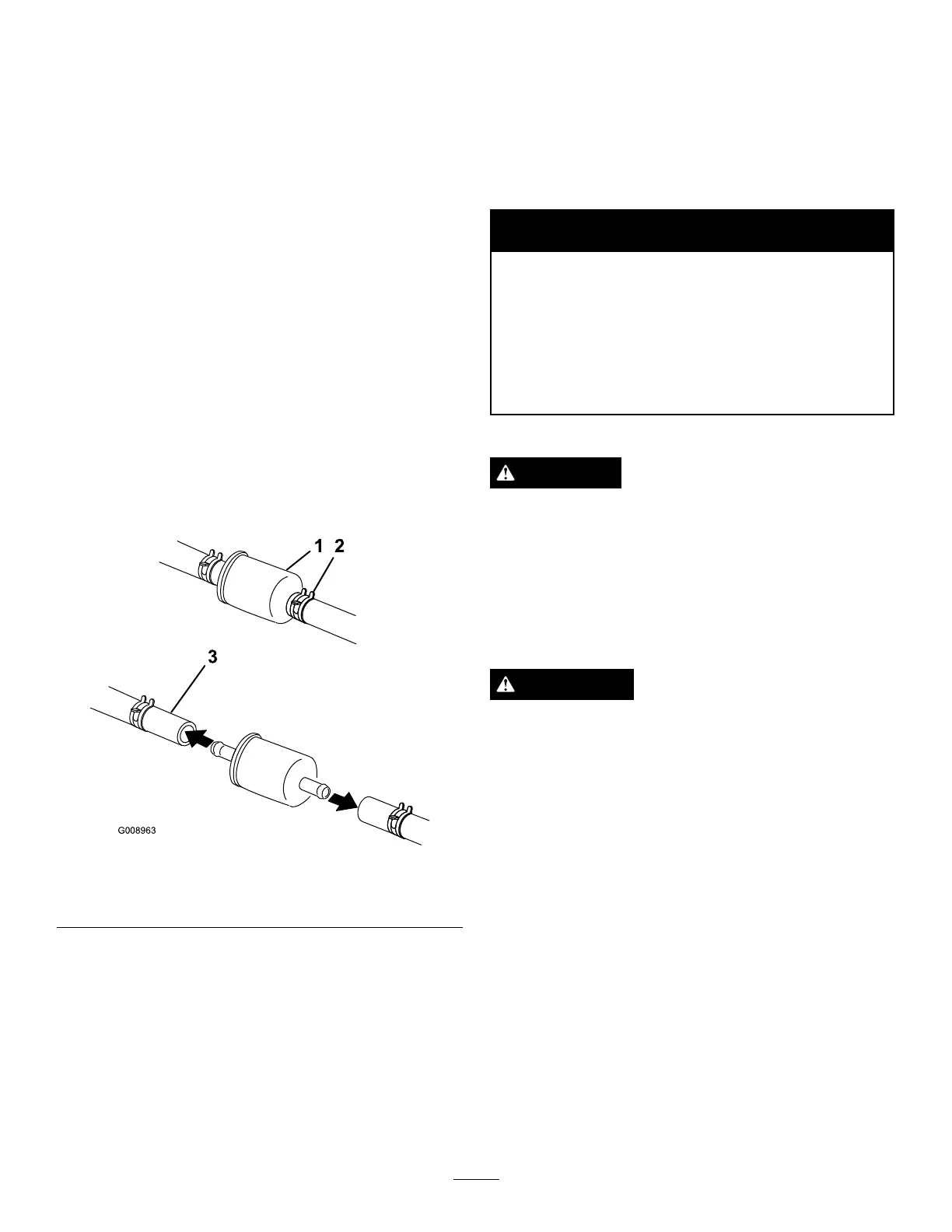

5.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(

Figure41).

Figure41

1.Fuellter

3.Fuelline

2.Hoseclamp

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclampsclose

tothelter(Figure41).

8.Openthefuelshutoffvalve.

Note:Itisimportanttoreinstallthefuellinehosesand

securewithplastictiesthesameastheywereoriginally

installedatthefactorytokeepthefuellineawayfrom

componentsthatcouldcausefuellinedamage.

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

34

Loading...

Loading...