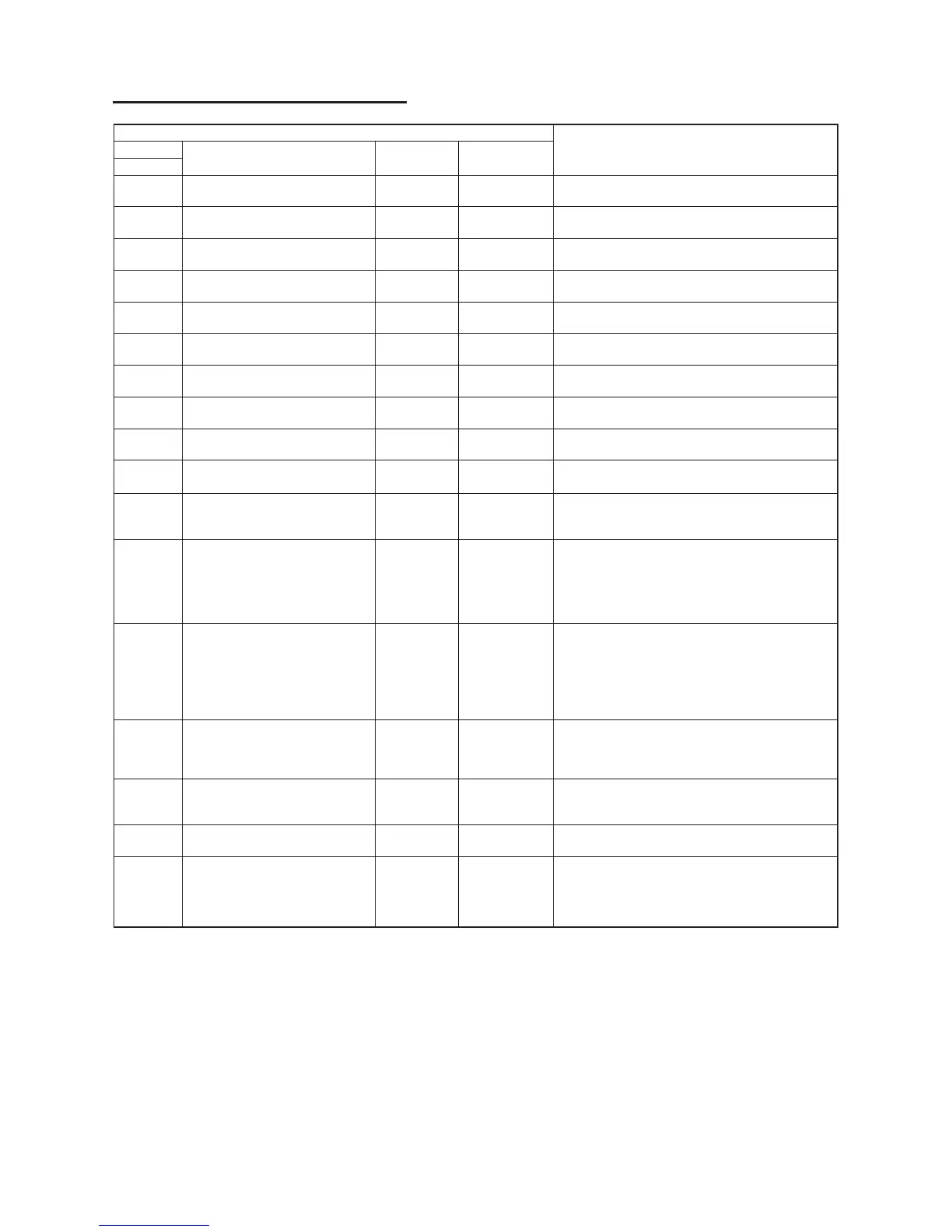

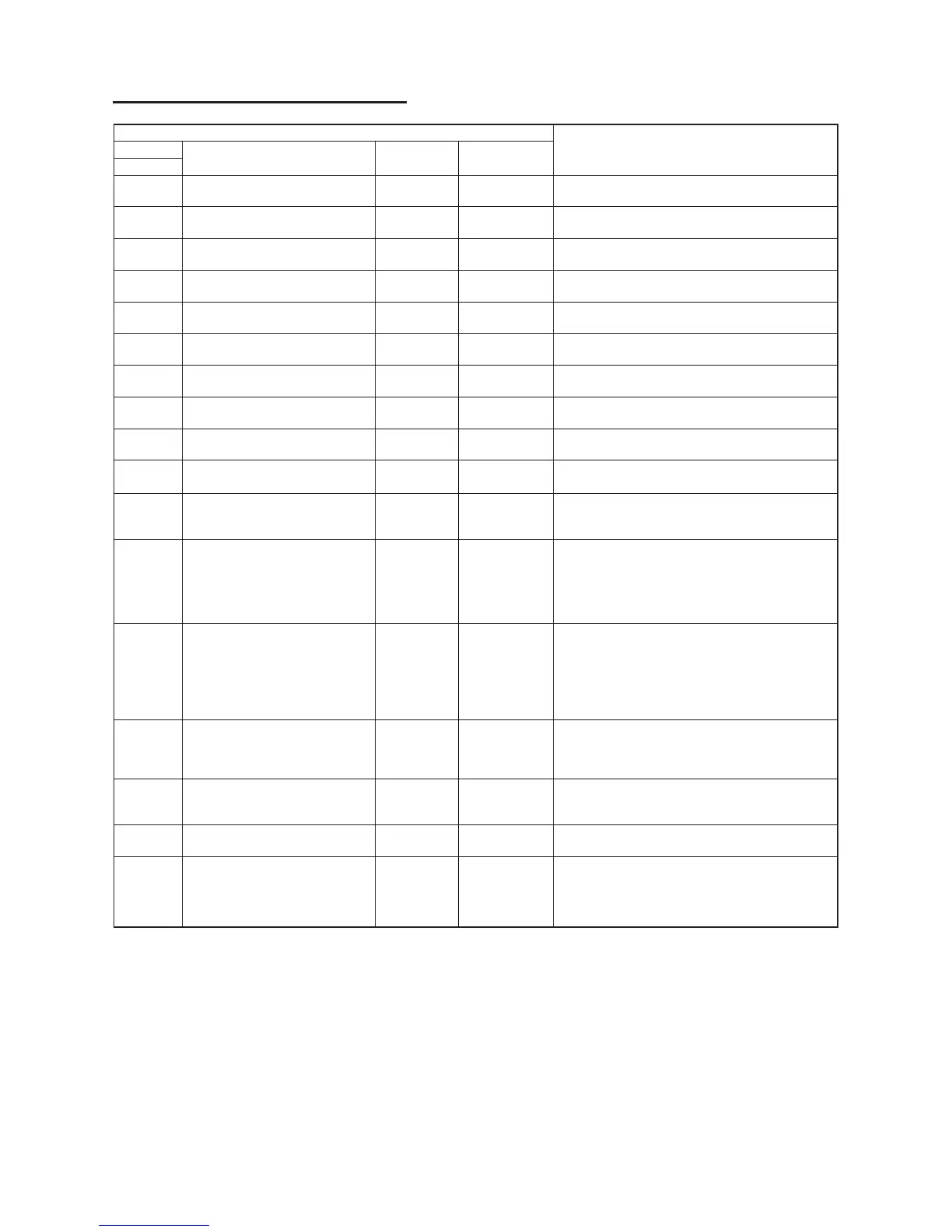

– 66 –

Failure mode detected by outdoor unit

Operation of diagnostic function

Check code

Status of

air conditioner

ConditionCause of operation

Judgment and measures

Indoor unit

F04

Disconnection, short of discharge

temp. sensor (TD)

Stop

Displayed when

trouble is detected

1. Check discharge temp. sensor (TD).

2. Check outdoor P.C. board (MCC-1705).

F06

Disconnection, short of outdoor temp.

sensor (TE)

Stop

Displayed when

trouble is detected

1. Check temp. sensor (TE).

2. Check outdoor P.C. board (MCC-1705).

F07

Disconnection, short of outdoor temp.

sensor (TL)

Stop

Displayed when

trouble is detected

1. Check temp. sensor (TL).

2. Check outdoor P.C. board (MCC-1705).

F12

Disconnection, short of suction temp.

sensor (TS)

Stop

Displayed when

trouble is detected

1. Check suction temp. sensor (TS).

2. Check outdoor P.C. board (MCC-1705).

F15

Miss-mounting of outdoor temp.

sensor (TE, TS)

Stop

Displayed when

trouble is detected

1. Check temp. sensor (TE, TS).

2. Check outdoor P.C. board (MCC-1705).

F08

Disconnection, short of outside temp.

sensor (TO)

Continue

Displayed when

trouble is detected

1. Check outside temp. sensor (TO).

2. Check outdoor P.C. board (MCC-1705).

F13

Disconnection, short of heat sink

temp. sensor (TH)

Stop

Displayed when

trouble is detected

L29

Communication trouble between

outdoor P.C. board MCU

Stop

Displayed when

trouble is detected

1. Check outdoor P.C. board (MCC-1705).

(Q201 is incorporated in TH sensor.)

F31Outdoor P.C. EEPROM trouble Stop

Displayed when

trouble is detected

1. Check outdoor P.C. board (MCC-1705).

L10 Unset jumper of service P.C. board Stop

Displayed when

trouble is detected

1. Outdoor service P.C. board

Check model type setting jumper wire.

1. Check outdoor P.C. board

(MCC-1705).

F23 Ps sensor trouble Stop

Displayed when

trouble is detected

1. Check connection of Ps sensor connector.

2. Check failure of Ps sensor.

3. Check compressing power trouble of compressor.

4. Check 4-way valve trouble.

5. Check outdoor P.C. board trouble.

P07

Heat sink overheat trouble

∗ Heat sink temp. sensor detected

over specified temperature.

Stop

Displayed when

trouble is detected

1. Check screw tightening between PC. Board and heat

sink and check radiator grease (MCC-1705).

2. Check heat sink blast path.

H02

Compressor lock

∗ Over-current detection after

compressor start-up

Stop

Displayed when

trouble is detected

1.

Trouble of compressor (Lock, etc.): Replace compressor.

2. Wiring trouble of compressor (Open phase)

H03 Current detection circuit trouble Stop

Displayed when

trouble is detected

1. Check outdoor P.C. board (MCC-1705).

(AC current detection circuit)

P15

Detection of gas leak

∗ Discharge temp. sensor (TD),

Suction temp. sensor (TS) detected

temperature over specified temp.

Stop

Displayed when

trouble is detected

1. Check gas leak, recharge

2. Check full open of service valve.

3. Check PMV (Pulse Motor Valve).

4. Check broken pipe.

5. Check discharge temp. sensor (TD), suction temp.

sensor (TS).

P19

4-way valve inverse trouble

∗ After heating operation has started,

indoor heat exchanger temp. lowers

under the specified temp.

∗ After heating operation has started,

outdoor heat exchanger / suction

temp. rises over the specified temp.

Stop

Displayed when

trouble is detected

1. Check operation of 4-way valve.

2. Check outdoor heat exchanger (TE), suction temp.

sensor (TS).

3. Check indoor heat exchanger sensor (TC).

4. Check 4-way valve coil.

5. Check PMV (Pulse Motor Valve).

H01

Compressor break down

∗ Although operation has started,

operation frequency decreases and

operation stops.

Stop

Displayed when

trouble is detected

1. Check power supply voltage. (AC198 to 264V)

2. Overload operation of refrigerating cycle

Loading...

Loading...