MAITENANCE MANUAL

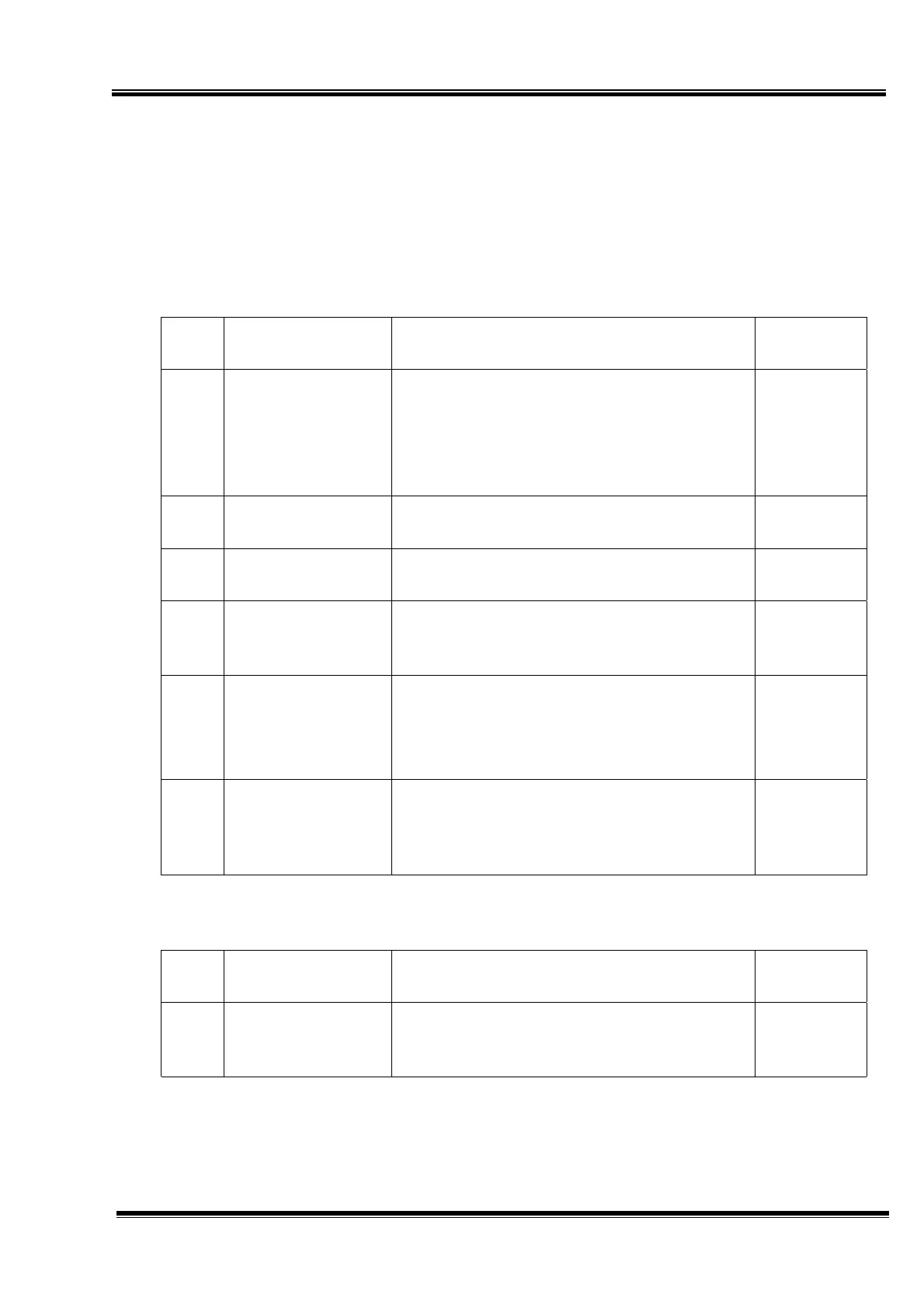

1.2 Items for Maintenance and Inspection

This section describes the items for maintenance and inspection. For the execution

procedures, see the relevant paragraph listed in the table below.

a) Daily inspection

No. Item Inspection procedures Relevant

Para.

1 Robot harness

and cable duct

Make sure that no local torsion or curve is

caused in the robot harness and cable

duct during robot operation.

Also, make sure that the robot harness is

tightened completely.

2.3.1

2 Robot installation

bolts

Make sure that the robot base installation

bolts are tightened completely.

2.3.1

3 Vibration and

noise

Make sure that each axis can move

smoothly.

2.3.1

4 Change in

positioning

accuracy

Make sure that the robot can stop at a

predetermined position accurately.

5 Controller vent

holes

(1) Make sure that no obstacle stands in

front of the vent holes.

(2) Make sure that no contaminant is left

in the vent hole.

3.3.1

6 Function of safety

devices

Make sure that each safety device

connected to the emergency stop

pushbutton switch and external operation

input signal can function properly.

3.3.2

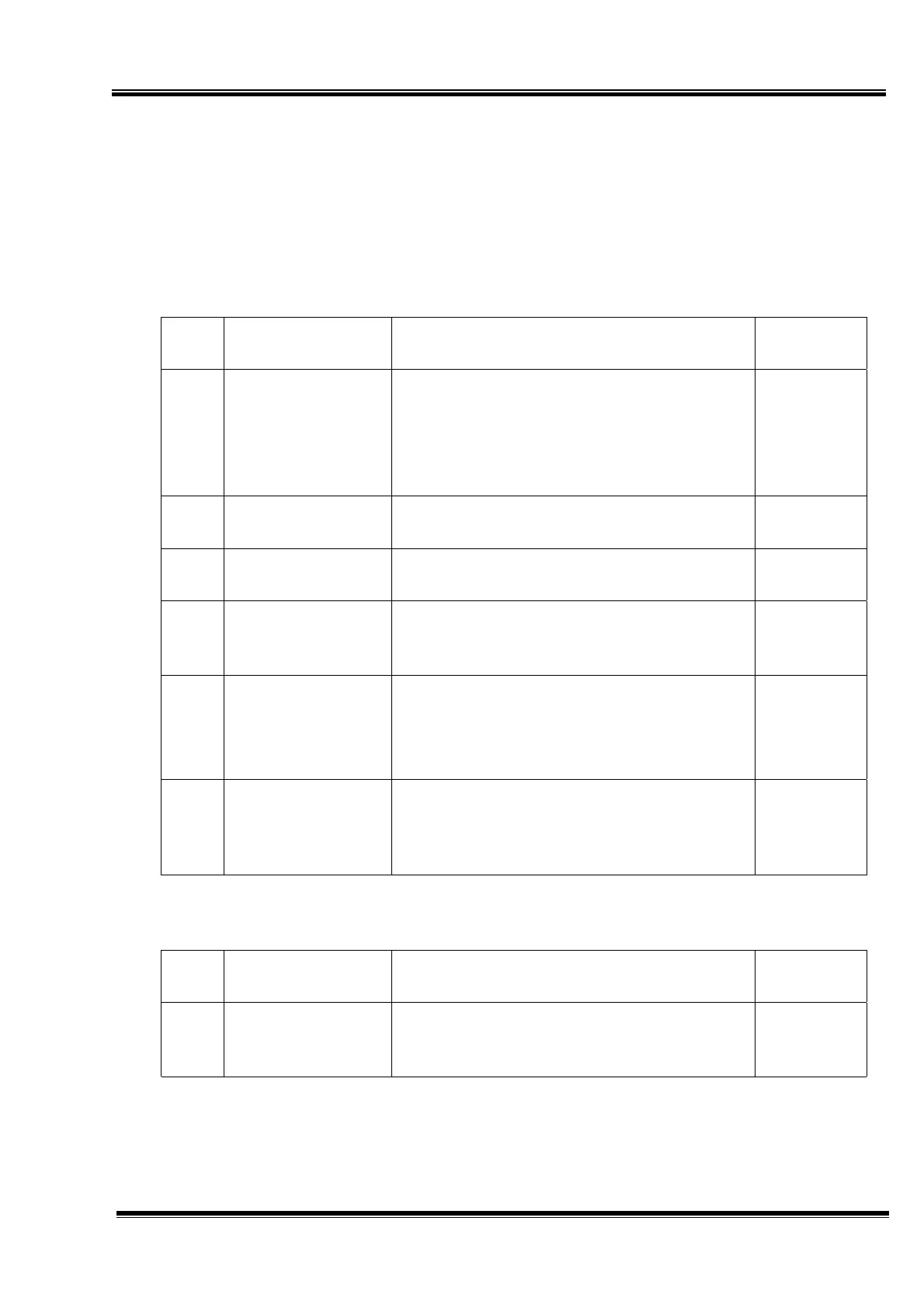

b) Quarterly (every three (3)-month) inspection

No. Item Inspection procedures Relevant

Para.

1 Lubricated state of

ball screw and

linear guide

Make sure that the ball screw and linear

guide of each axis is greased completely

and that no rust is developed on them.

2.3.2

STE 73872

– 1–2 –

Loading...

Loading...