48

E6582383

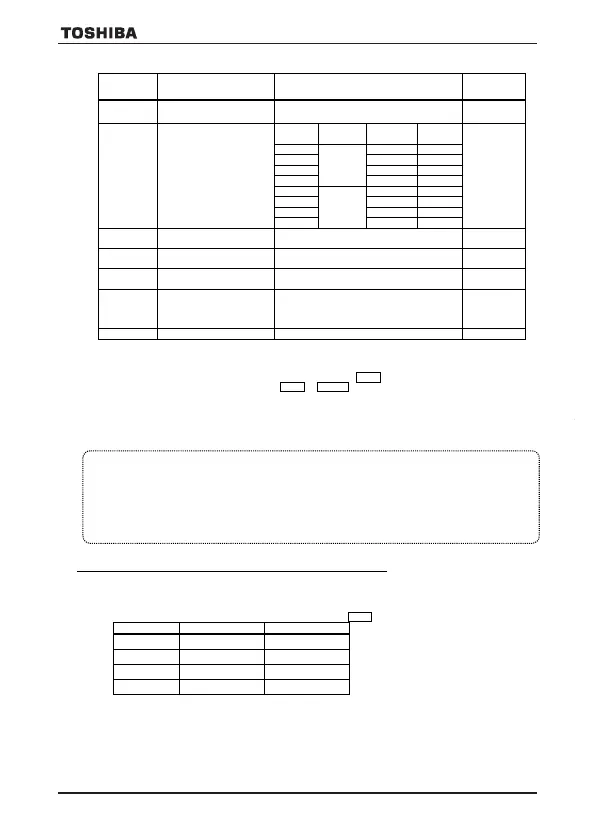

[Parameter setting]

Title Function Adjustment range

Default

setting

Motor electronic-thermal

protection level 1

10 – 100 (%) 100

Electronic-thermal

protection characteristic

selection

Setting

Overload

Overload

0

Standard

motor

1 valid valid

4

VF motor

(special

motor)

valid invalid

7 invalid valid

f173

Motor electronic-thermal

protection level 2

10 – 100 (%) / (A) 100

f607

Motor 150% overload

10 – 2400 (s)

300

Inverter overload detection

1: Temperature estimation

0

Electronic-thermal memory

0: Disabled (thr, f173)

1: Enabled (thr, f173)

2: Disabled (thr)

thr

0

Note) (Only for -W1 model)

aul must be set to default setting (1: Constant torque characteristic) for the compliance with UL standard.

1) Setting the electronic thermal protection characteristics selection

o

l

m

and motor electronic thermal protection level 1

t

h

r

, 2

f

1

7

3

The electronic thermal protection characteristics selection (olm) is used to enable or disable the motor overload trip

function (ol2) and the overload stall function.

While the inverter overload trip (ol1) will be in constantly detective operation, the motor overload trip (ol2) can be

selected using the parameter olm

Explanation of terms

Overload stall: This is an optimum function for equipment such as fans, pumps and blowers with variable torque

characteristics that the load current decreases as the operating speed decreases.

When the inverter detects an overload, this function automatically lowers the output frequency before the motor

overload trip (ol2) is activated. With this function, operation can be continued, without tripping, by operating

using a frequency balanced by load current.

Note: Do not use the overload stall function with loads having constant torque characteristics (such as conveyor

belts in which load current is fixed with no relation to speed).

[Using standard motors (other than motors intended for use with inverters)]

When a motor is used in the lower frequency range than the rated frequency, that will decrease the cooling effects for

the motor. This speeds up the start of overload detection operations when a standard motor is used in order to prevent

overheating.

Setting of electronic thermal protection characteristics selection olm

0 valid invalid

1 valid valid

2 invalid invalid

3 invalid valid

E6582383

14

×0.6

×1.0

Output frequency (Hz)

Output current reduction factor

[%]/[A]

0

Note: The motor overload protection start level is fixed at 30Hz.

×1.0

Output frequency (Hz)

Output current reduction factor

[%]

/

[A]

0

6Hz

×0.6

Note) The start level for motor overload reduction is fixed at 6 Hz.

Setting of motor electronic thermal protection level 1 thr (Same as f173)

When the capacity of the motor in use is smaller than the capacity of the inverter, or the rated current of the motor

is smaller than the rated current of the inverter, adjust thermal protection level 1 thr for the motor in

accordance with the motor's rated current.

[Using a VF motor (motor for use with inverter)]

Setting of electronic thermal protection characteristics selection olm

Setting value

Overload stall

valid invalid

valid valid

invalid invalid

invalid valid

VF motors (motors designed for use with inverters) can be used in frequency ranges lower than those for

standard motors, but their cooling efficiency decreases at frequencies below 6Hz.

Setting of motor electronic thermal protection level 1 thr (Same as f173)

If the capacity of the motor is smaller than the capacity of the inverter, or the rated current of the motor is

smaller than the rated current of the inverter, adjust the electronic thermal protection level 1 so that it fits

the motor's rated current.

2) Motor 150%-overload detection time

ff660077

Parameter f607 is used to set the time elapsed before the motor trips under a load of 150% (overload trip 2)

within a range of 10 to 2400 seconds.

3) Inverter overload detection method

ff663311

As this function is set to protect the inverter unit, this function cannot be turned off by parameter setting.

The inverter overload detection method can be selected using parameter f631 (Inverter overload detection method).

If the inverter overload trip function (ol1) is activated frequently, this can be improved by adjusting the stall operation

level f601 downward or increasing the acceleration time acc or deceleration time dec.

= (150%-60s)

Protection is given uniformly regardless of temperature by the 150%-60 sec overload curve.

= (Temperature estimation)

This parameter adjusts automatically overload protection, predicting the inverter internal temperature rise.

4) Electronic thermal memory

ff663322

When the power is OFF, it is possible to reset or maintain the overload totaling level.

This parameter's settings are applied both to the motor's electronic thermal memory and the electronic thermal memory

for inverter protection.

VF-S15_QS.indb 48VF-S15_QS.indb 48 2021/11/18 15:51:562021/11/18 15:51:56

E6582383

13

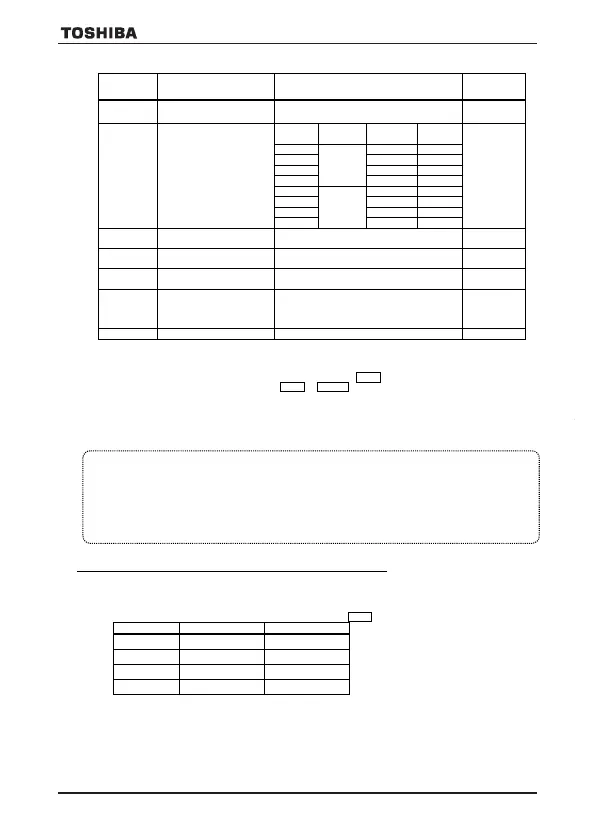

[Parameter setting]

Title Function Adjustment range

Default

setting

Motor electronic-thermal

protection level 1

10 – 100 (%) 100

Electronic-thermal

protection characteristic

selection

Setting

(special

motor)

valid invalid

7 invalid valid

f173

Motor electronic-thermal

protection level 2

10 – 100 (%) / (A) 100

f607

Motor 150% overload

10 – 2400 (s)

300

Inverter overload detection

1: Temperature estimation

0

Electronic-thermal memory

0: Disabled (thr, f173)

1: Enabled (thr, f173)

2: Disabled (thr)

Note) (Only for -W1 model)

aul must be set to default setting (1: Constant torque characteristic) for the compliance with UL standard.

1) Setting the electronic thermal protection characteristics selection

oollmm

and motor electronic thermal protection level 1

tthhrr

, 2

ff117733

The electronic thermal protection characteristics selection (olm) is used to enable or disable the motor overload trip

function (ol2) and the overload stall function.

While the inverter overload trip (ol1) will be in constantly detective operation, the motor overload trip (ol2) can be

selected using the parameter olm

Explanation of terms

Overload stall: This is an optimum function for equipment such as fans, pumps and blowers with variable torque

characteristics that the load current decreases as the operating speed decreases.

When the inverter detects an overload, this function automatically lowers the output frequency before the motor

overload trip (ol2) is activated. With this function, operation can be continued, without tripping, by operating

using a frequency balanced by load current.

Note: Do not use the overload stall function with loads having constant torque characteristics (such as conveyor

belts in which load current is fixed with no relation to speed).

[Using standard motors (other than motors intended for use with inverters)]

When a motor is used in the lower frequency range than the rated frequency, that will decrease the cooling effects for

the motor. This speeds up the start of overload detection operations when a standard motor is used in order to prevent

overheating.

Setting of electronic thermal protection characteristics selection olm

0 valid invalid

1 valid valid

2 invalid invalid

3 invalid valid

Output frequency (Hz)

Output current reduction factor

[%]/[A]

0

Note: The motor overload protection start level is fixed at 30Hz.

×1.0

Output frequency (Hz)

Output current reduction factor

[%]

/

[A]

0

6Hz

×0.6

Note) The start level for motor overload reduction is fixed at 6 Hz.

Setting of motor electronic thermal protection level 1 thr (Same as f173)

When the capacity of the motor in use is smaller than the capacity of the inverter, or the rated current of the motor

is smaller than the rated current of the inverter, adjust thermal protection level 1 thr for the motor in

accordance with the motor's rated current.

[Using a VF motor (motor for use with inverter)]

Setting of electronic thermal protection characteristics selection olm

Setting value

Overload stall

valid invalid

valid valid

invalid invalid

invalid valid

VF motors (motors designed for use with inverters) can be used in frequency ranges lower than those for

standard motors, but their cooling efficiency decreases at frequencies below 6Hz.

Setting of motor electronic thermal protection level 1 thr (Same as f173)

If the capacity of the motor is smaller than the capacity of the inverter, or the rated current of the motor is

smaller than the rated current of the inverter, adjust the electronic thermal protection level 1 so that it fits

the motor's rated current.

2) Motor 150%-overload detection time

f

Parameter f607 is used to set the time elapsed before the motor trips under a load of 150% (overload trip 2)

within a range of 10 to 2400 seconds.

3) Inverter overload detection method

f

As this function is set to protect the inverter unit, this function cannot be turned off by parameter setting.

The inverter overload detection method can be selected using parameter f631 (Inverter overload detection method).

If the inverter overload trip function (ol1) is activated frequently, this can be improved by adjusting the stall operation

level f601 downward or increasing the acceleration time acc or deceleration time dec.

= (150%-60s)

Protection is given uniformly regardless of temperature by the 150%-60 sec overload curve.

= (Temperature estimation)

This parameter adjusts automatically overload protection, predicting the inverter internal temperature rise.

4) Electronic thermal memory

f

When the power is OFF, it is possible to reset or maintain the overload totaling level.

This parameter's settings are applied both to the motor's electronic thermal memory and the electronic thermal memory

for inverter protection.

VF-S15_QS.indb 49VF-S15_QS.indb 49 2021/11/18 15:51:562021/11/18 15:51:56

VF-S15_QS_CC2021.indd 48VF-S15_QS_CC2021.indd 48 2021/11/18 15:55:332021/11/18 15:55:33

Loading...

Loading...