- 5 -

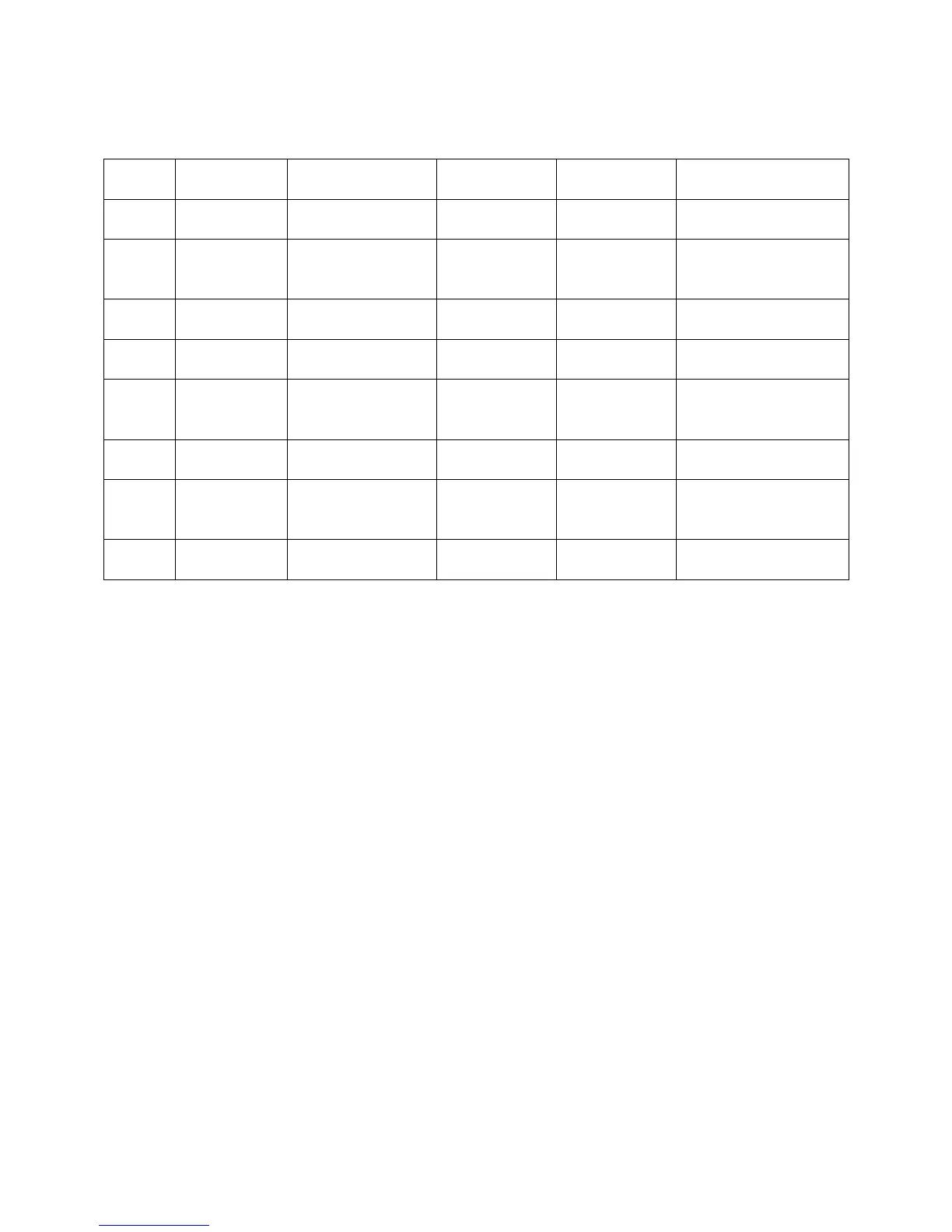

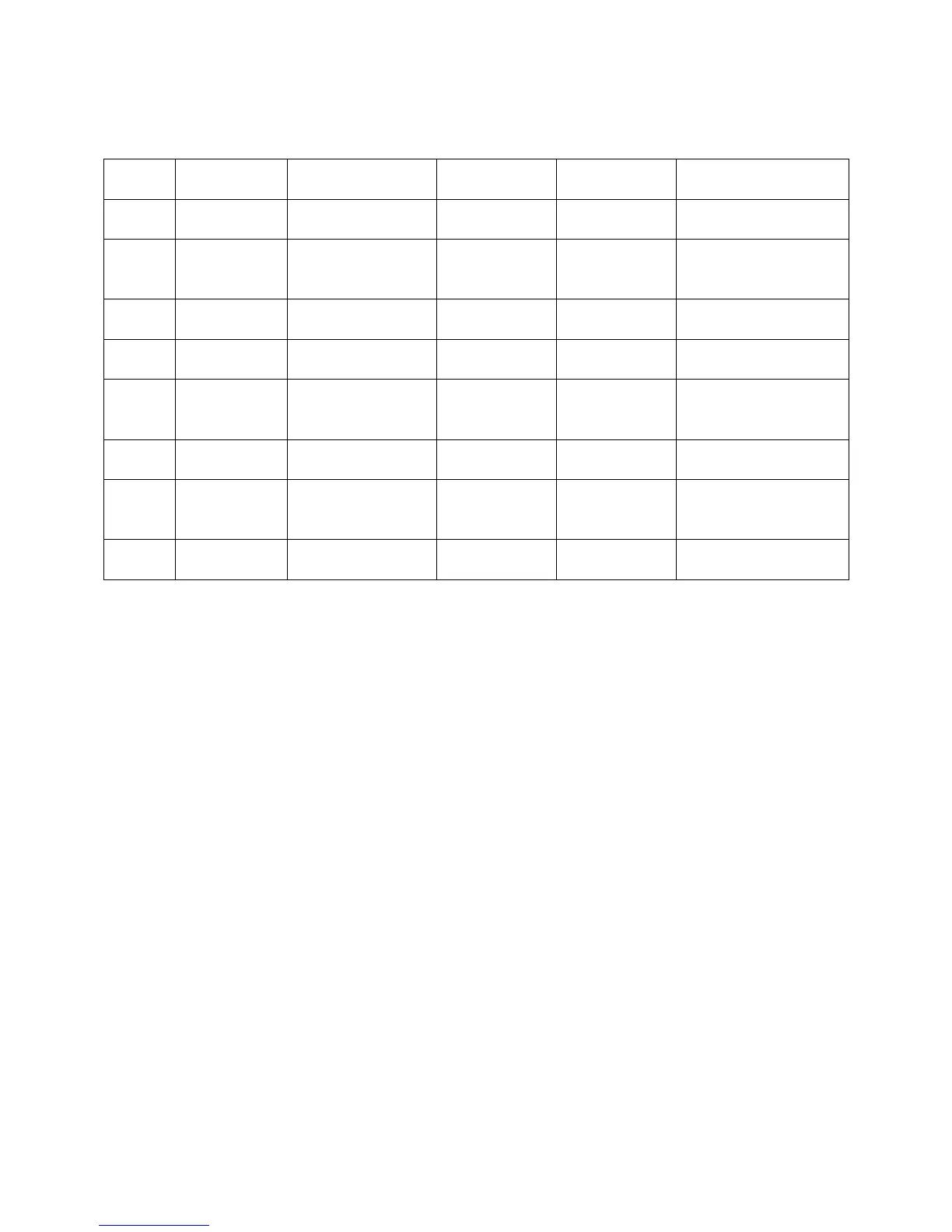

METER OPERATING SPECIFICATIONS

1½”NPT Flange;

2” optional

-40°F to 160°F

(-40°C to 71°C)

SP, SPA,

SPD, IP, IC,

AF & SS

2” NPT Flange;

1½”optional

-40°F to 160°F

(-40°C to 71°C)

2” NPT Flange;

1½”optional

-30°F to 140°F

(-30°C to 60°C)

-40°F to 160°F

(-40°C to 71°C)

SP, SPA,

SPD, IP, IC

& AF

-40°F to 160°F

(-40°C to 71°C)

-40°F to 160°F

(-40°C to 71°C)

SP, SPA,

SPD, IP, IC

& AF

4” NPT Flange;

3” optional

-40°F to 160°F

(-40°C to 71°C)

-40°F to 160°F

(-40°C to 71°C)

* Flanged NPT is Standard; BSPT, Slip Weld, ANSI and others are available upon request.

** Higher working temperatures can be achieved at reduced pressures (consult factory for more information)

METER SELECTION FACTORS

WEIGHTS&MEASURES

Before any meter can be specified, knowledge of each application is required. If the liquid is to

be sold through a metered delivery, domestic or international certification from a governing body

may be required. Total Control Systems strictly adheres to all domestic and international

metrology conformance regulations for the custody transfer of fluids. For questions regarding

weights and measures approvals or other issues, please consult factory.

Loading...

Loading...