2

10

Fig. 2 -

24

Fig. 2·

25

ENGI

NE

TUNE

-

UP

- Spark Plugs. High Tension Cord

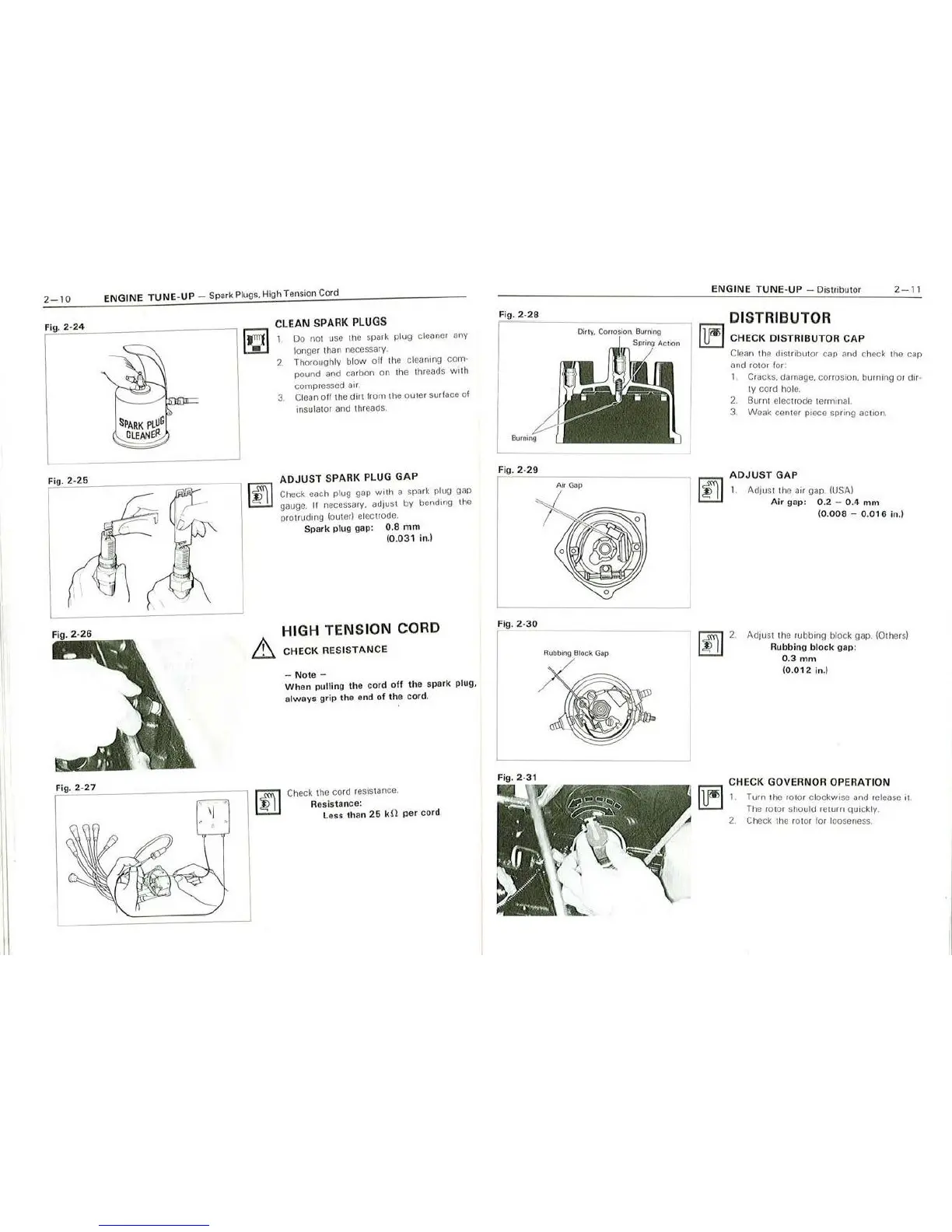

CLEAN SPARK PLUGS

~

1

.

Do

no1

u

se

1h

e spark pl

ug

cleaner any

longer than necessary.

2. Thoroughly bl

ow

o

ll

the cleaning

co

m-

pound and carb

on on

th

e threads

w11h

compressed au

3.

Cl

ean

ofl the d

irt

from the o uter surface of

insulator and threads.

ADJUST

SPARK

PLUG

GAP

Check each plug gap

with

a spark ptug gap

gauge.

If

necessary. adjust

by

bending

th

e

pro1rud1ng

(o

ut

er)

elecirode.

Spark plug gap:

0.8

mm

(0.

03

1 in.l

HIGH TENSION CORD

&

CHECK

RESISTA

NCE

-

Note

-

When

pulling

the

cord

off

the

spark plug,

always

grip the end

of

the

cord.

Fig.

2·

27

__________

_

._.'I

,.

l

~

Check the cord resistance .

Resistance:

less

than

25

k

C!

per

cord

Fig,

2·

28

Fig. 2-

29

Fig. 2-

30

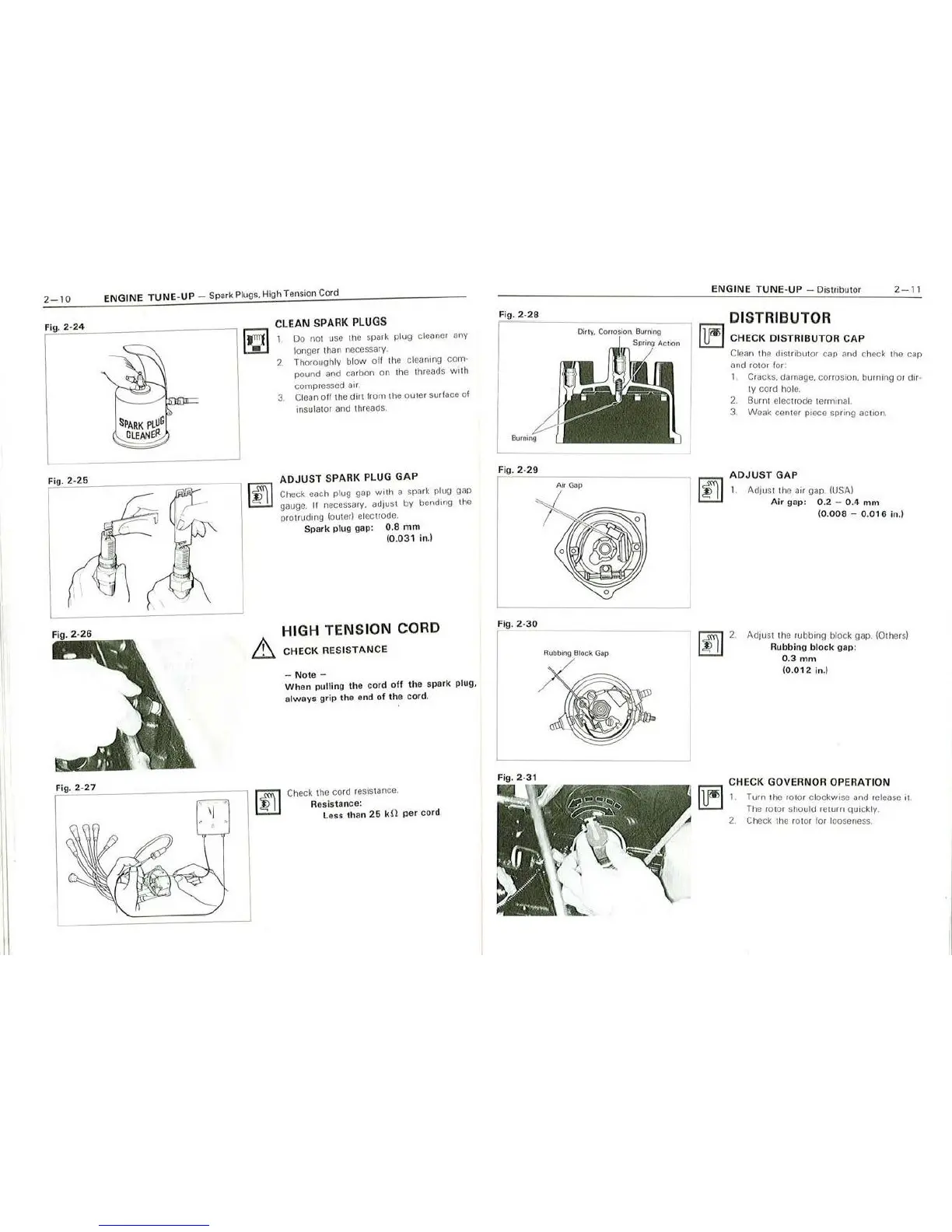

Oirty, Co

rr

·

os.ion.

Burn

t

ng

Spring Action

Air

Ga.P

Rubbing

Block

Gap

ENG

IN

E

TU

NE-

UP

Distributor 2 11

DIS

TR

IBUTOR

CHECK

DI

STRIBUTOR

CAP

Clean 11

1e

distributor cap and check

1he

cap

and rotor f

or

:

I. Cracks. damage. corrosion. burning or clir·

ty cord hol

e.

2 Burn! electrode terminal.

3 Weak cent

er

piece spri

ng

ac11on

.

ADJUST

GAP

1

~

1

Adjust

th

e air gap. (USA)

Air gap:

0.2

- 0 .4

mm

(0.

008

- 0.

016

i

n.)

Ad1us1

t

he

rubbing block gap. (Others)

Rubbing

block

gap:

0.3

mm

(0.

012

In.)

CHECK

GOVERNOR

OPERA

T

IO

N

~

I.

Tu

rn

lh

e

ro

t

or

clockwise and release

1L

The rotor should return

qu

ickly.

2. Check

th

e ro1or for looseness.

Loading...

Loading...