3 -

38

Fig.

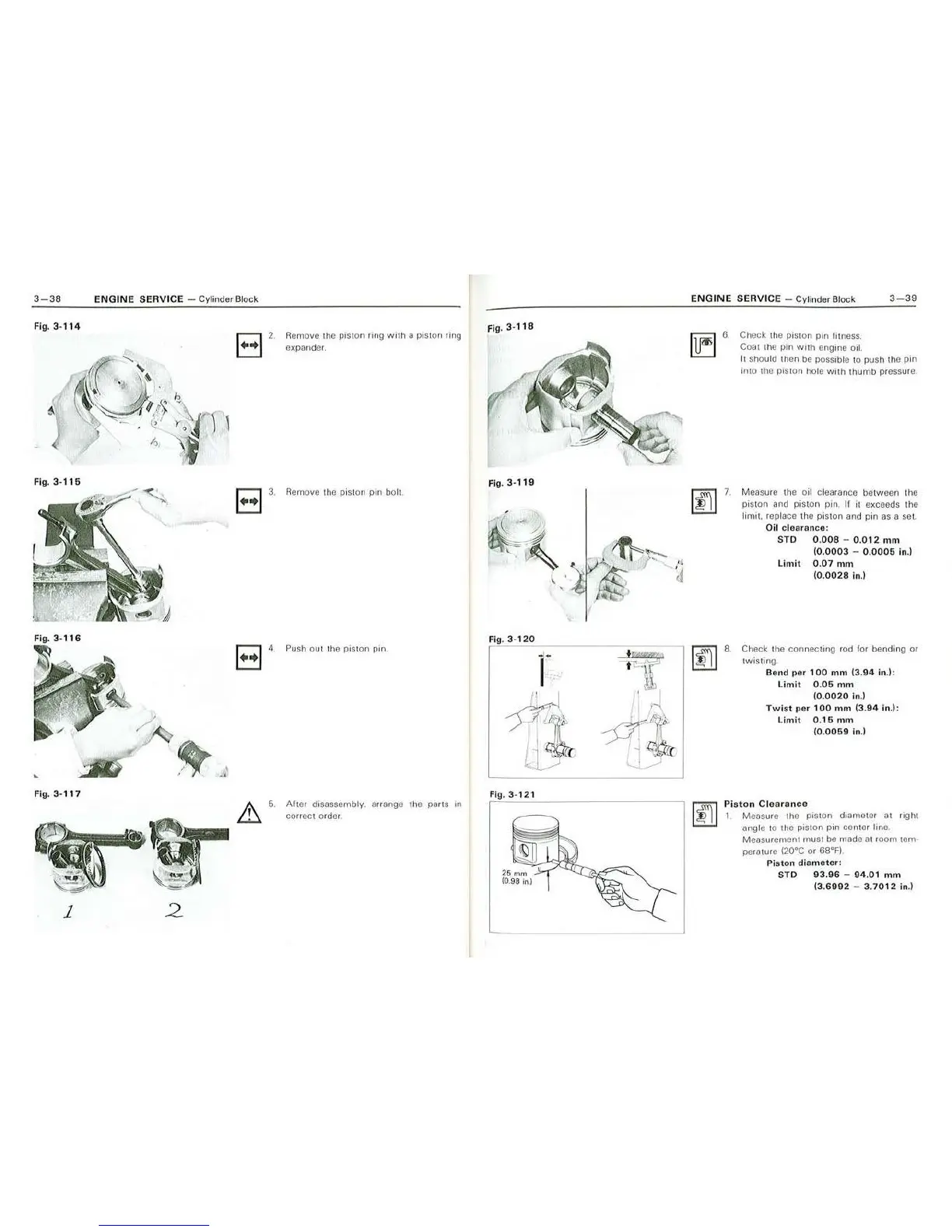

3-114

Fig. 3-

117

1

ENGI

NE

SERVICE

- Cylinder Block

..

El

2.

Rem

ove

th

e piston ring with a piston ring

expand

er.

r::J 3. Remove

th

e piston p

11

1 bolt.

~

2

Push out

th

e pi

s1on

pin.

Alter

disassembly. arrange 1he pans m

cor

r

ect

orde

r.

Fig. 3-

118

Fig.

3-119

Fig.

3·

120

Fig

.

3-

121

E

NGINE

SERVICE

- Cylin

de

r Block

3-39

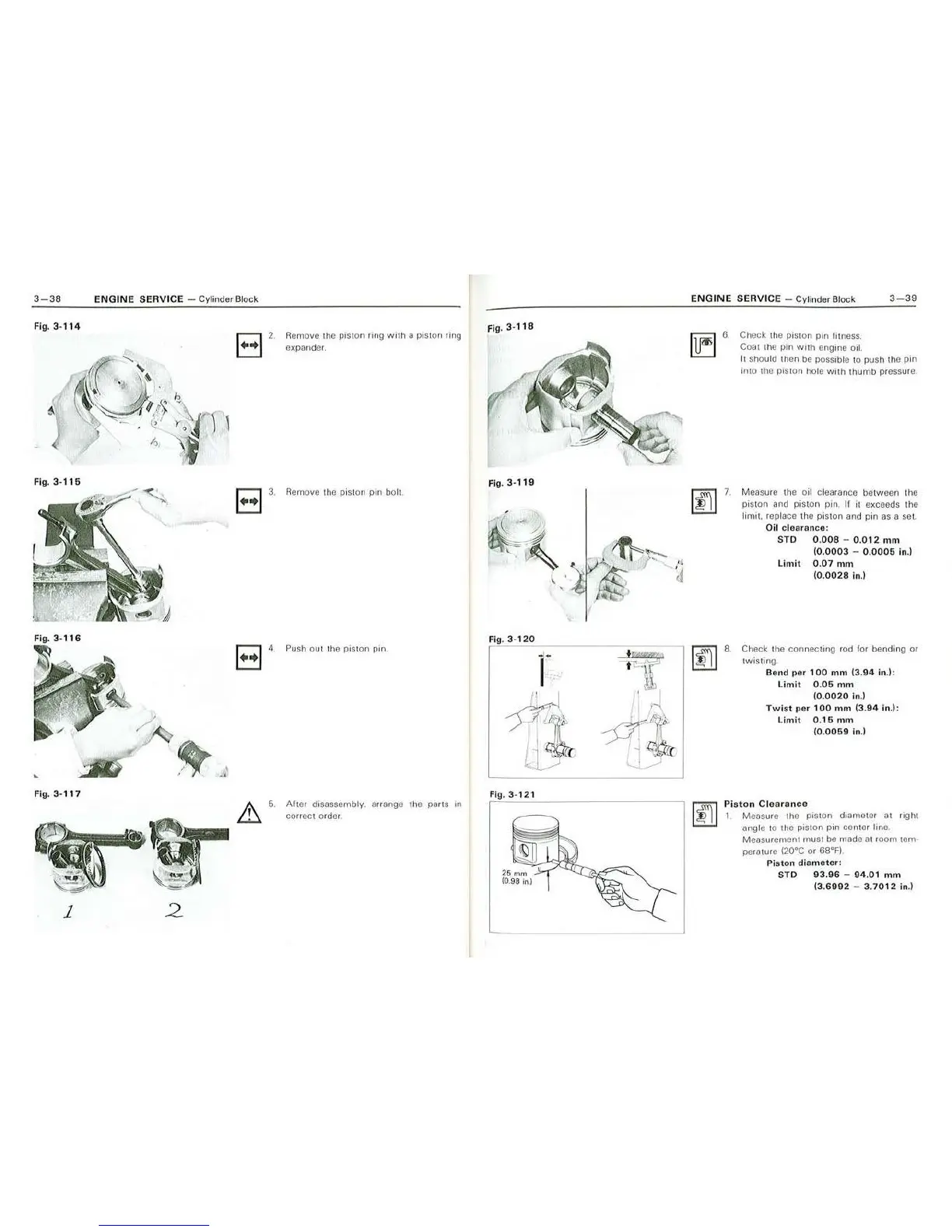

~

7

.

~

8

.

Check

th

e pi

s1o

n pin lirness.

Coat !he

pin

wuh

engine oil.

It should th

en

be

possible 10 push

1he

pin

into

the pis ton hole

whh

thu

mb

pressure.

Measure the

oi

l cl

ea

rance between the

pist

on

and pist

on

pin

. II it exceeds

1he

li

mit

re

place

th

e piston and pin as a set.

Oil clearance:

STD

0.008

-

0.012

mm

(0.0003

- 0.

0005

in.I

Limit

0.

07

mm

(0.

0028

in.)

Check

1he

connecting rod for bending

or

tw

is

ti

ng.

Bend per

10

0

mm

(3.94

in

.):

Lim

it

0.05

mm

(0.

0020

In

.)

Twist

per

100

mm

(3.

94

in.):

Li

n1

it 0.

16

n1m

(0.

0059

i

n.)

Piston

Clear

ance

I Measure tho piston diameter a 1 rig ht

angle to the piston pin center line.

Measurernen

t

1nu

st

be

made

at

room

tam

·

perature (20°C or 68°F)

Piston

diameter

:

S

TD

93.96

- 94.01

mm

(3.6992

-

3.

7012

in.)

Loading...

Loading...