3-

36

fig

.

3-106

Fig.

3-107

Fig. 3 -

108

I

Fig. 3-

109

ENGINE SERVICE - Cylinder Block

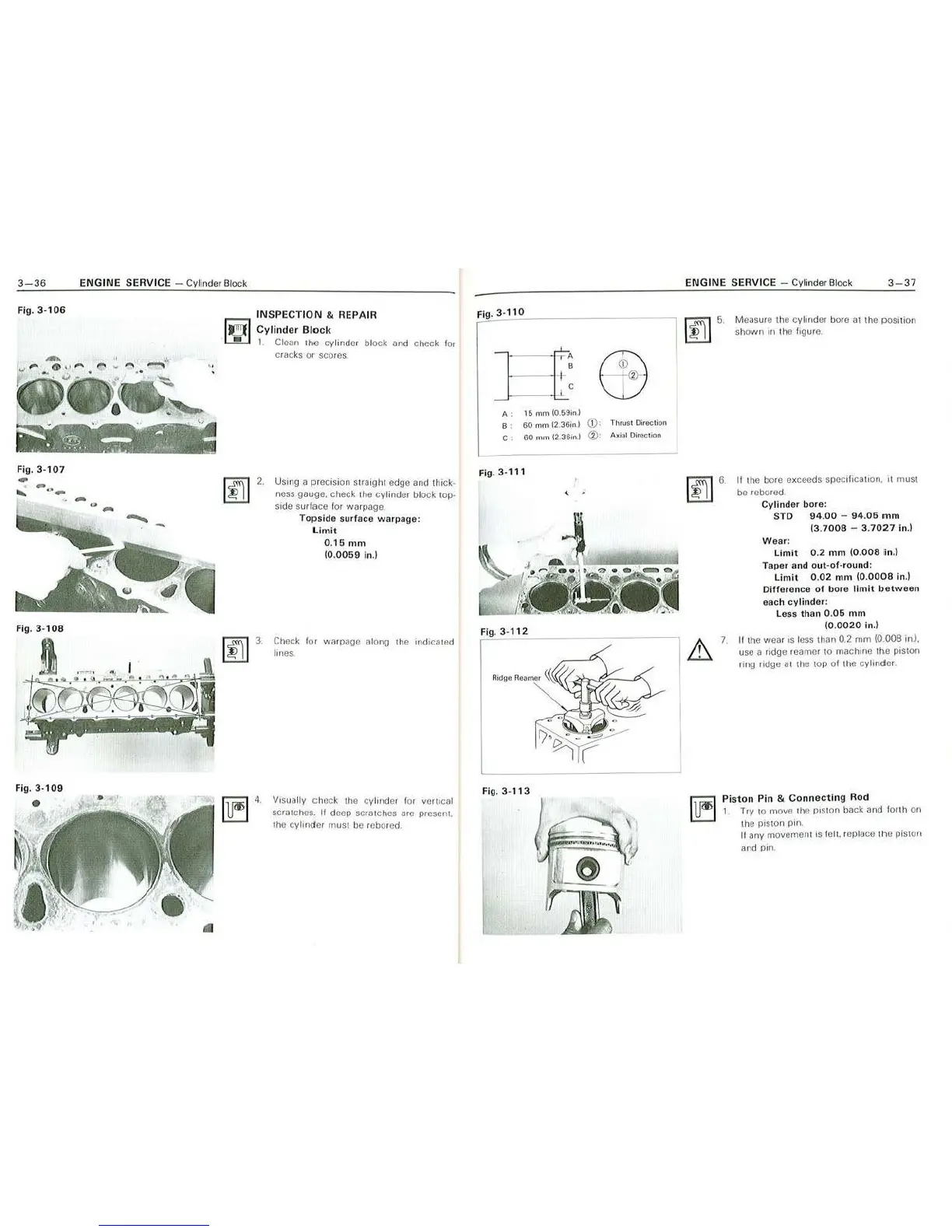

INSPECTION & REPAIR

Cylinder

Bl

ock

I.

Cl

ean

lhe

cylinder block and check 1

01

crac

ks or

score

s.

Using a precision s1ra

igh1

e

dg

e and

th

ick·

n

ess

ga

u9

e.

check 1 he

cyl

i

nde1

block 1op.

side surface f

or

warp

age

.

T

ops

i

de

s

urf

a

ce

warpag

e:

Limit

0.

15

mm

(0.

0059

in.I

Check for warpage along

th

e

ind

1c

a 1ed

lines

~

4

.

Visually c heck

1he

cyl1nde1

fo1

vertical

scra1ch

es.

If deep

sc1a1

ches arc presenl.

lhe

cylinder

rnus1

be

reborcd.

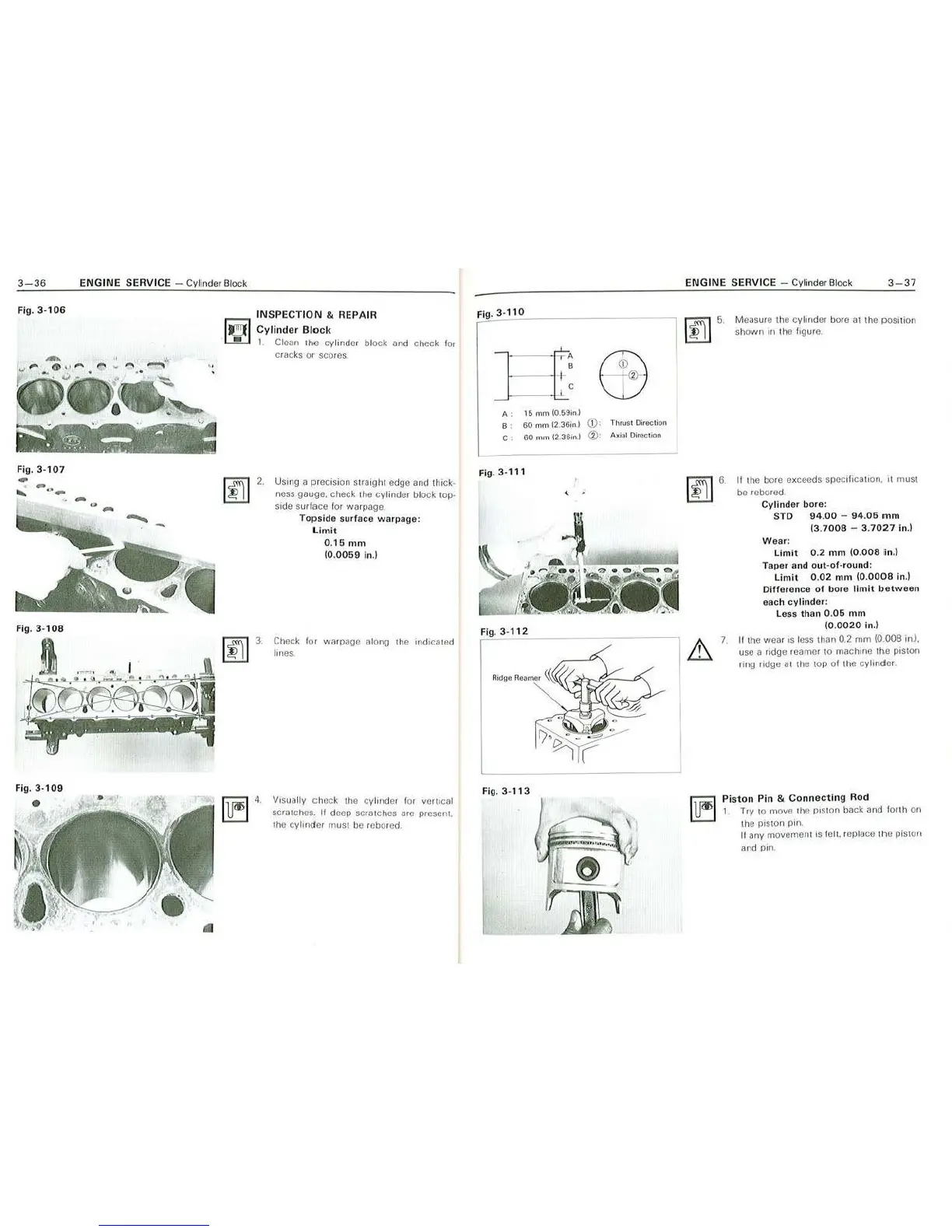

Fig.

3-

110

A : 15

mm

(0.

59in)

8 :

60

mm

12

.

36i

n}

© :

Th

r

usl

Oireetion

C :

60

01m

(2

.

361n.l

®: A

lda

l

Dire

ction

Fig. 3·

111

Fig. 3·

112

ENGINE SERVICE - Cylinder Block

3-

37

[fl] 6.

Measure 1he cy

l111

d

e1

bore

at

lhc

POSll

ion

shown in

th

e

hg

u

re.

If the

bore

exceeds

spcc1hcat1on

. n must

be rebored.

Cy

linder bore:

STD

94.00

-

94

.

05

•

nm

(3.

7008

- 3.

7027

in

.)

Wea

r:

Limit

0.2

mm

(0.008

un.l

Taper

and out-of-round:

Limit

0.

02

mm

(0

.

0008

in.I

Difference

of

bore

limit

between

each

cylinder

:

Less than 0.

05

mm

(0.

0020

in.I

If

1h

e

we

ar

os

less 1han

0.2

mm

{0.0

08 in I.

u

se

a

ridg

e

1ea1ner

to

machi

ne

1h

e p

iston

ring ridge at the top or the cy

lin

der

Piston

Pin

&

Connecting

Rod

I Try to move the pis1on back and t

onh

o"

1h

e

pis1o

n pi

n.

If

any movement is lelt. replace lhe pist

on

and pin

Loading...

Loading...