Metalyser

®

Portable HM1000

Instruction Manual

v 5.0

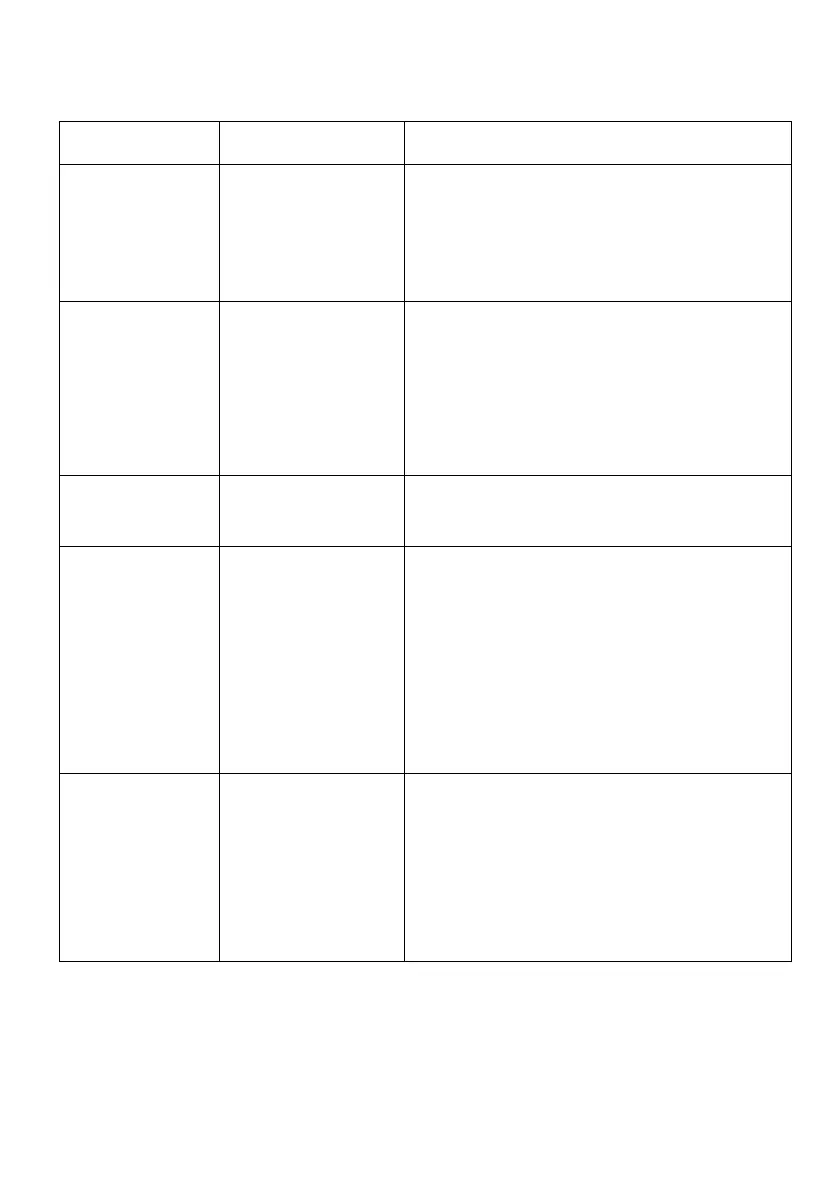

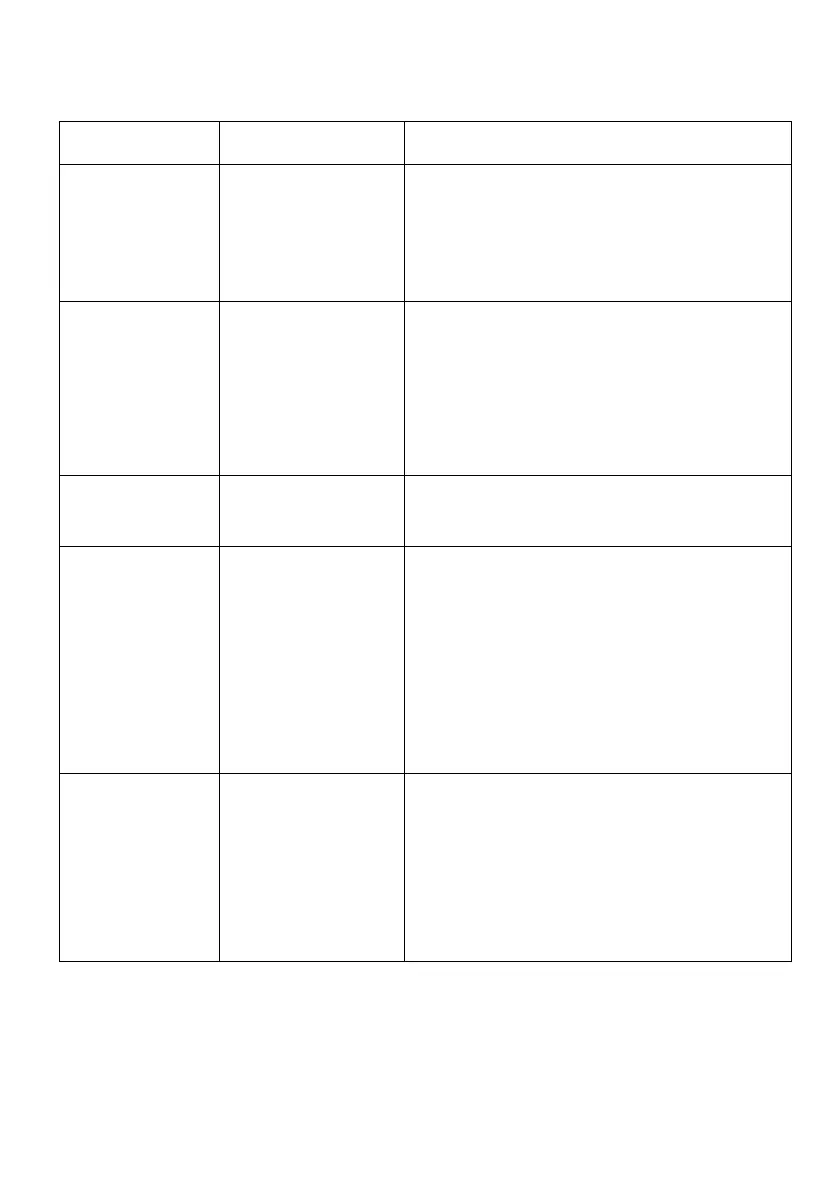

Conditioning step

not completed

Wipe end of Working Electrode, polish and

re-condition as per procedure

No heavy metals in

solution

Test with known amount of standard solution

Results lower

than expected

Ensure stirrer is rotating by looking into the

SAB or lighting touching the bottom to

determine stirrer is working, if the stirrer is

stuck, use stirrer oil as described on page 13

Physical mask over

the electrode

Ensure no debris – for example, leaves – are

physically masking the electrode surface,

preventing the analysis from occurring

Results

increasing with

each run

Instrument is not designed to deal with strong

organics; system is for natural rivers and

water courses

The Metalyser

®

has been designed for low

level ppb analysis in natural water. The

instrument will measure high limits by

a) choosing a shorter deposition time (i.e.

change default from 60 to 30 seconds when

prompted in the Set Deposition time menu

during the course of the run)

b) diluting the sample by a known amount

and multiplying the result back to the original

solution

Metalyser

®

not

responding to

key press

First turn off the Metalyser

®

, wait for a few

seconds and then turn it back on. If this does

not fix the problem, disconnect the battery

and reconnect. If the fault persists, contact

the supplier to organise a return

Disconnect Metalyser

®

from Metaware, turn

of the Metalyser

®

and then turn it back on

after a few seconds. This should give control

back to the Metalyser

®

.

Loading...

Loading...