LOADING FASTENERS INTO THE NAILER/STAPLER

Never point any operational fastener driving tool at

yourself or at any other person.

LOADING THE FASTENERS:

1. Disconnect the air hose

2. Depress the magazine latch (A). Pull back on the

magazine cover.

3. Insert a stick of fasteners into the magazine.

BRAD NAILS: Make sure the pointed ends of the

fasteners are resting on the bottom edge of the

magazine.

STAPLES: Make sure the staples rest on the

TOP of the magazine, with the open end of staple

pointing down

4. Push the magazine cover forward until the latch

catches.

FEATURES AND OPERATION

FEATURES

Large capacity magazine with a quick action latch makes loading easy.

The safety lock on the nosepiece must be placed firmly onto the work surface to prevent

accidental firings.

A tapered nosepiece allows greater visibility for precise fastener placement.

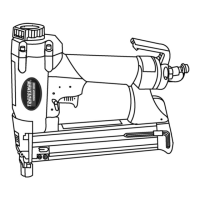

A safety switch (Fig. A) that prevents accidental operation of the tool. The switch is located

inside the trigger. To lock the trigger, pull the cover of trigger towards the rear of the unit. To

unlock tool, release (push forward) the cover of trigger. A key lock or tie strip can be place

into the slot for safety storage of unit.

FASTENER DEPTH ADJUSTMENT

The contact trip (Fig. B) may be adjusted up or down to vary the depth of the fastener in the

workpiece. To adjust, rotate the depth adjustment until the desired setting is achieved

.

The tool is designed to operate between 70-120 PSI. Lower pressure (below 70 PSI) will

reduce performance of the tool while higher air pressure (over 120 PSI) raises the performance

of the tool beyond its rated capacity and could cause serious damage to the tool and the user.

Most applications will only require the minimum air pressure. However, larger fasteners and

harder woods may require air pressure in the upper range.

TESTING THE CYCLE OF THE TOOL

NOTE:

THE AIR SUPPLY SHOULD BE CLEAN AND DRY. FOR BEST RESULTS, DRAIN

THE MOISTURE FROM YOUR COMPRESSOR DAILY. CHECK AND REPLACE ANY

DAMAGED OR WORN COMPONENTS ON THE TOOL. THE SAFETY WARNING LABELS

ON THE TOOL MUST ALSO BE REPLACED IF THEY ARE NOT LEGIBLE. IN CASE THE

AIR TOOL IS UNABLE TO DRIVE THE FASTENER INTO THE WORKPIECE COMPLETELY,

PLEASE ADJUST THE PRESSURE OF THE AIR COMPRESSOR TO AN APPPROPRIATE

PRESSURE.

Depress the contact safety trip mechanism

against the workpiece without pulling the trigger.

The tool must not cycle. Never use the tool if a

cycle occurs.

Hold the tool clear of the workpiece. The contact

safety trip mechanism should return to its original

down position. Pull the trigger. The tool must not

cycle. Do not use the tool if a cycle occurs.

Then depress the contact safety mechanism

against the workpiece and pull the trigger, the tool

must then cycle.

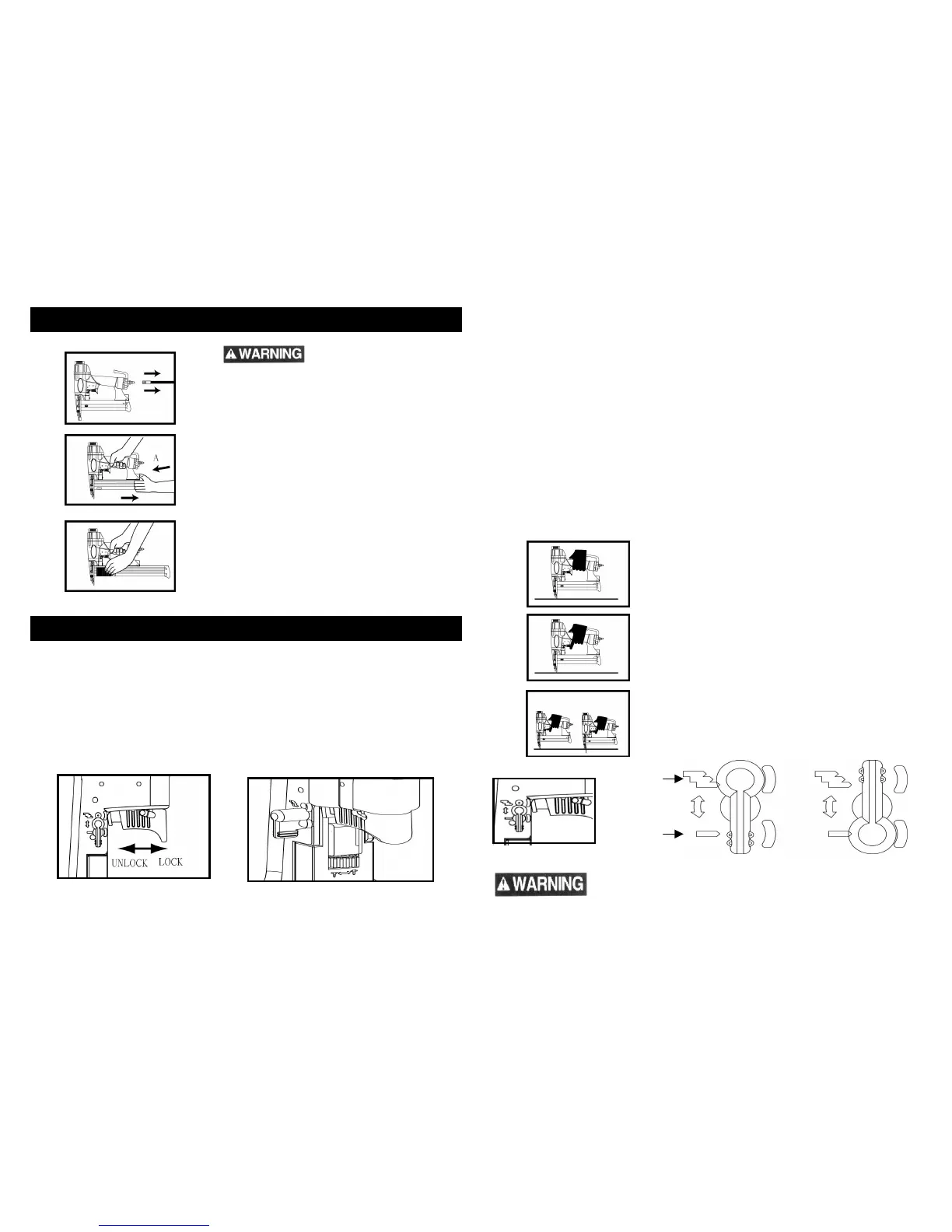

The air tool is equipped with a rotating switch (Fig. C)

that can be set to rapid-fire or single-fire mode.

Fig. C

SINGLE-FIRE RAPID-FIRE

Rapid-Fire

Single-Fire

Fig. A Fig. B

Loading...

Loading...