Offset Mowers 33 Trailblazer Attachments, LLC

423-405-5150 February 2019

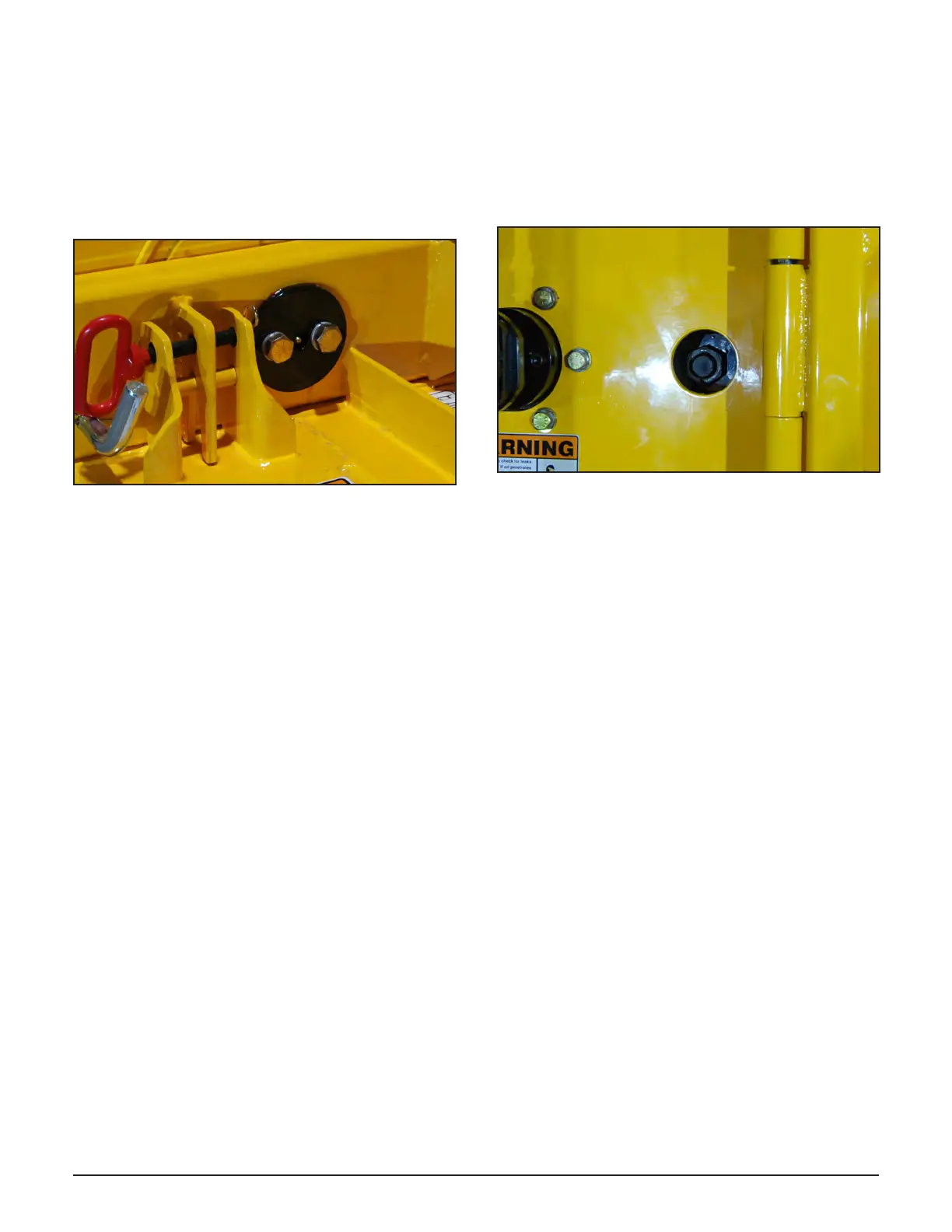

8.2 Mower Deck Pivot Arm Bearing

The mower deck will hang slightly downward when

it’s in the offset vertical position (hanging from the

tractor) due to its weight. This is normal. If angle seems

excessive, recheck the retaining bolts.

Retighten the tapered roller bearing in the pivot arm

after 15 minutes of initial use and again at 30 minutes.

Recheck again before the next use.

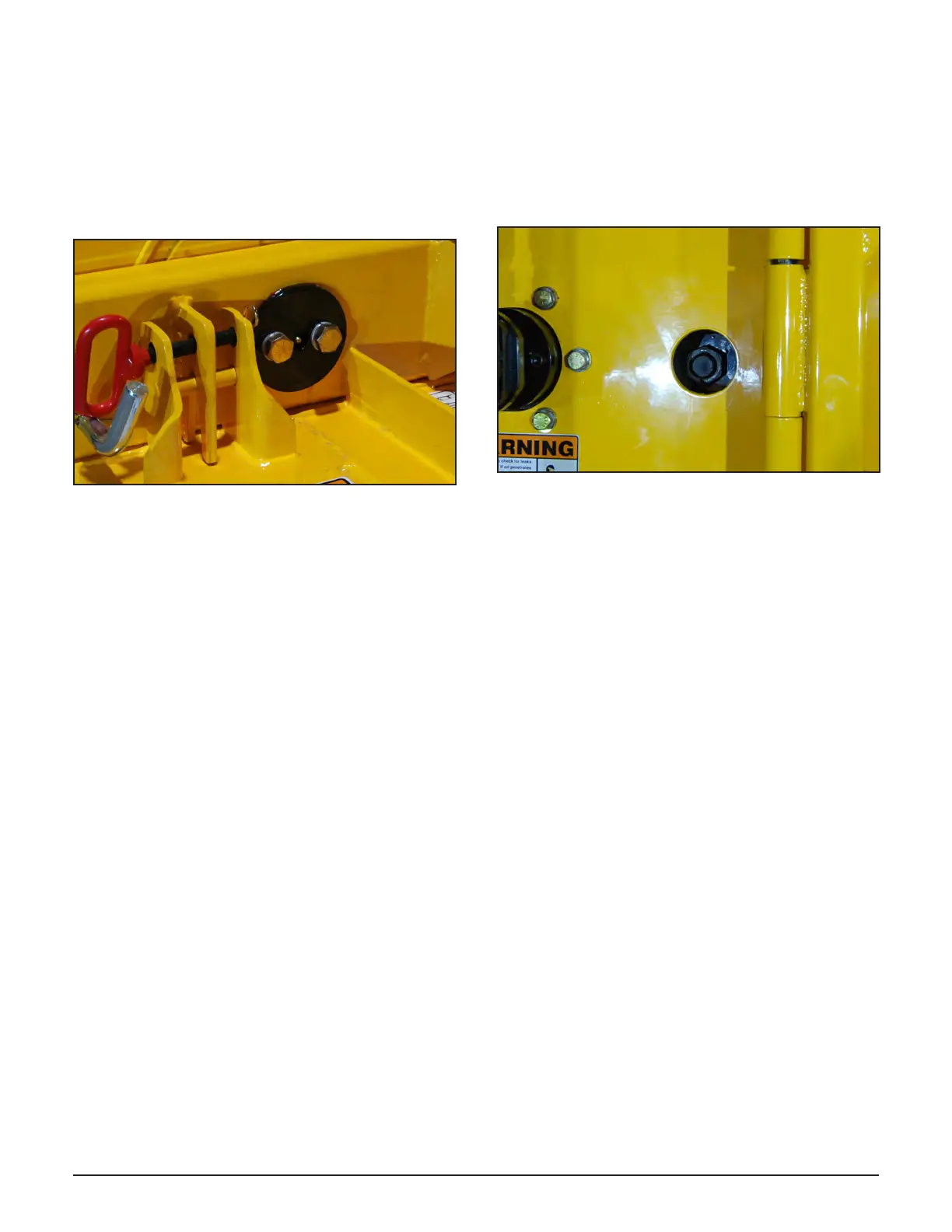

8.3 Greasing

Grease all zerks according to the schedule in

“8.7 Service Record” on page 34. Use an SAE

multipurpose high-temperature grease with extreme

pressure (EP) performance. Also acceptable is an SAE

multipurpose lithium base grease.

1. Always use a handheld grease gun for all greasing.

2. Wipe grease zerks with a clean cloth before

greasing to avoid injecting dirt and grit.

3. Apply grease until new grease can be seen coming

out of the joint.

4. Do not let excess grease collect on or around parts,

particularly when operating in sandy areas.

5. Replace and repair broken grease zerks

immediately.

6. If any grease zerk will not take grease, remove

and clean it thoroughly. Also, clean the lubricant

passageway. Replace the zerk if necessary.

8.4 Blade Servicing

Inspect blades before each use to determine that they

are properly installed and in good condition. If any

blade is bent, excessively nicked, worn, or has any

other damage, replace both blades. Do not sharpen

the blades. The blades have two cutting edges

and should be ipped when the rst edge is dull or

damaged.

Manually wiggle the blade carrier to check for

any looseness. Recheck torque every fty hours.

Retighten any loose parts.

8.4.1 Blade Removal

To remove blades, remove the nut and lockwasher

from the blade bolt through the inspection hole in the

deck of the mower near the gearbox.

8.4.2 Blade Installation

When installing blades, be sure to check the blade bolt

pivot diameter for wear. Replace the bolt if worn more

than 1/4 inch at any point. Tighten nut to 600 ft. lbs.

Always use a new lockwasher and nut when replacing

the blade bolt. Make sure blades are installed with the

cutting edge in the direction of rotation. Rotation is

counterclockwise as viewed from above the deck.

8.4.3 Blade Sharpening

DO NOT SHARPEN THE BLADES.

The mower blades are two-sided and can be ipped

over once to create a new cutting edge. Once both

cutting edges have been used the blades MUST be

replaced.

8.5 Blade Carrier Removal

1. Remove the cotter pin and loosen the castle nut on

the gearbox shaft. Do not remove the nut until the

blade carrier is loosened.

2. Use a suitable two jaw gear puller to pull the carrier

off the tapered gearbox shaft.

3. If a gear puller is not available, insert a bar through

the blade bolt the access hole with the end against

the blade carrier. Strike the opposite end of the bar

sharply. Rotate the blade carrier 180 degrees and

repeat until the carrier breaks loose.

4. Remove the castle nut and the blade carrier.

Loading...

Loading...