Water Piping Connections

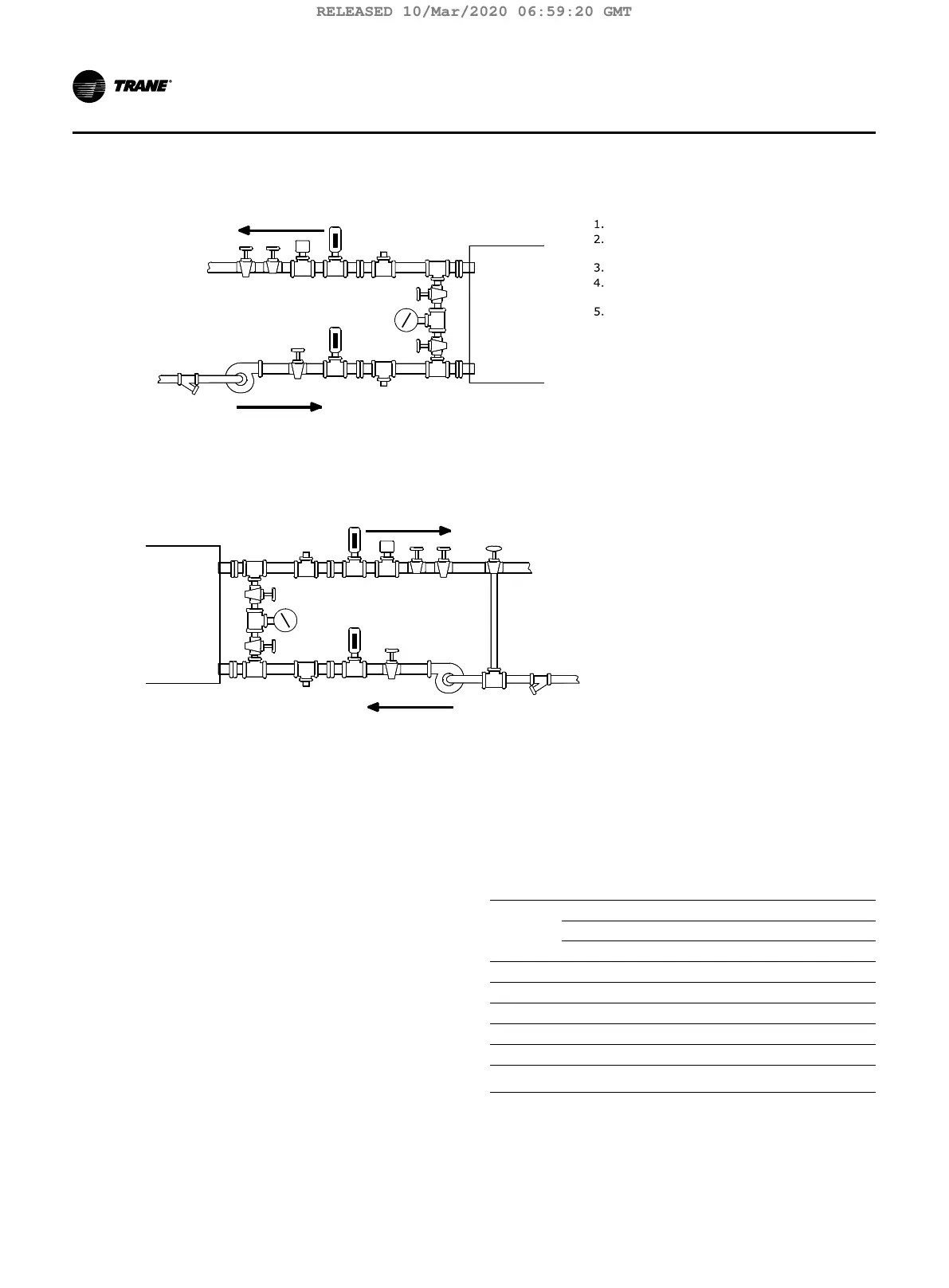

Figure 9. Typical evaporator water piping circuit

Valve

Thermometer (if field supplied)

Gate (Isolation) Valveor Ball

Flanged Connection 1/2” (13 mm

NPT Couplings

Drin, Vent, Anode

tes:

1.

water circuit.

2.

Flow switch 5S1 (Itemin Legend of Components) maybe installed in either the entering or leaving leg of the chilled

allows the operator to read either entering or leaving water pressure.

It is recommended to pipe the gauge between entering and leaving pipes. A shutoff valve on each side of the gauge

44

445

53

3

2

12

2

2

Inlet

Outlet

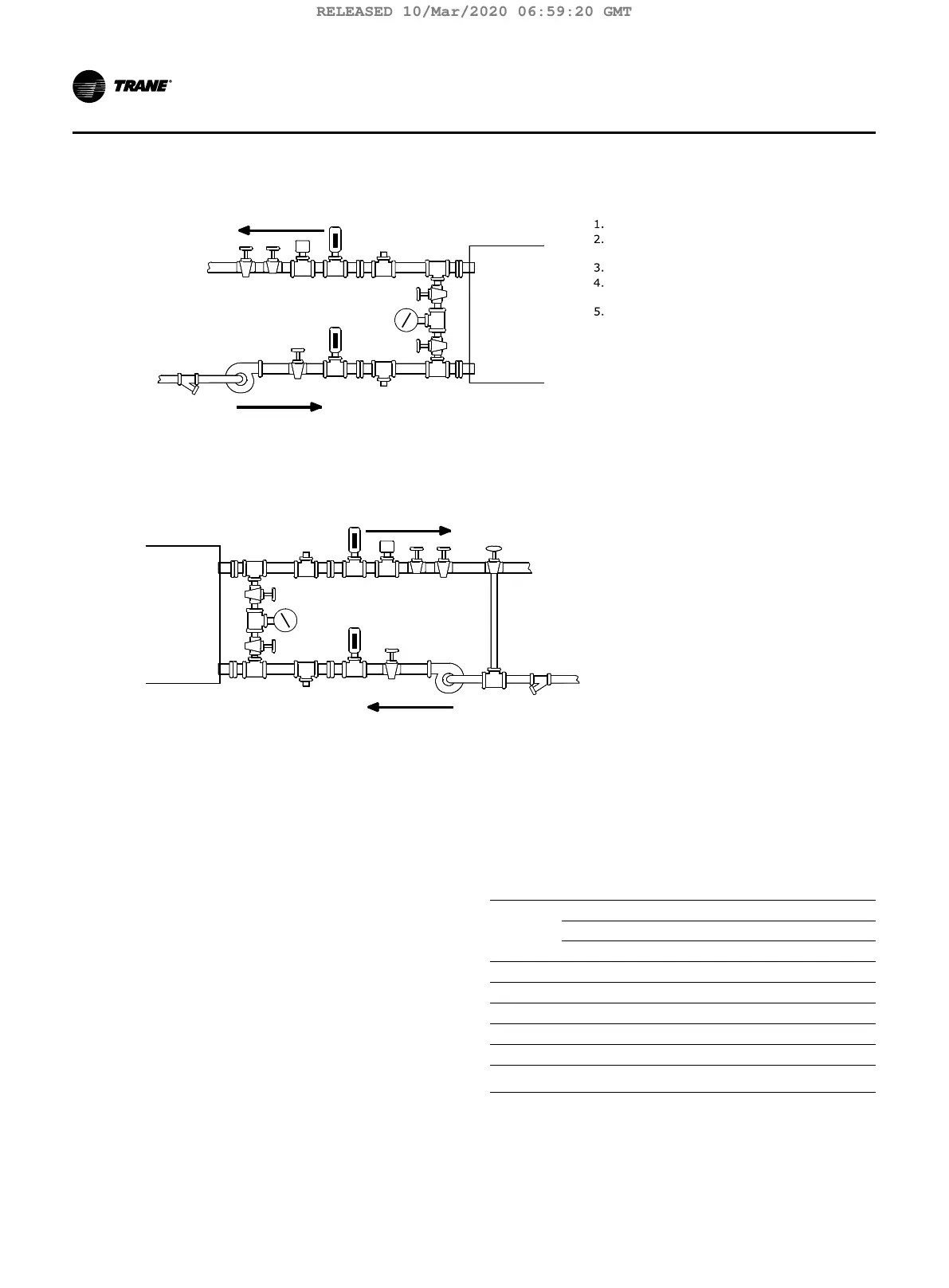

Figure 10. Typical condenser water piping circuits

2.

3.

Gate (Isolation) Valve or Ball Valv

4.

Thermometer (if field supplied)

5.

Flanged Connection 1/2” (13 mm)

NPT Couplings

6.

7.

Strainer

Drain, Vent, Anode

8.

Condenser Water Flow Switch (5S1

9.

3-Way Valve (Optional)

10.

Condenser Water Pump

Notes:

1.

Pressure Gauge

2.

water circuit.

3.

The Flow Switch 5S2 (Item 7 in Legend of Components) may be installed in either the entering or leaving leg of the chilled

It is recommended to pipe a single gauge between entering and leaving pipes.

4.

Some type of field-supplied temperature control device may be required to regulate the temperature of the heat-recovery

condenser water circuit. For application recommendations, see Trane Application Manual, “AM-FND-8”, titled “Heat-

Recovery Engineering Seminar”.

Install a bypass valve system to avoid circulating water through the auxiliary shell when the unit is shut down.

On multiple pass condensers, entering condenser water must enter at the lowest nozzle.

1

2

3

54

6

78

9

2

34

445

2

2

10

Outlet

Inlet

All standard units use grooved-pipe connections. These

are cut-groove end NSP (Victaulic™ style) pipe connec-

tion. Flanged connections for 300 PSI waterboxes use

welded flanges.

Piping joined using grooved type couplings, like all types

of piping systems, requires proper support to carry the

weight of pipes and equipment. The support methods

used must eliminate undue stresses on joints, piping

and other components; allow movement where required,

and provide for any other special requirements (i.e.,

drainage, etc.).

Note: Plug-type sensor extension cables are available

for purchase from Trane Parts Service if needed.

These sensor extension cables may be necessary

if the waterboxes are changed or if the tempera-

ture sensors are moved out into the unit piping

for better mixed temperature readings.

Table 2. Evaporator water piping connection sizes

EVSZ

ominal Pipe Size

1 Pass 2 Pass 3 Pass

Inch mm Inch mm Inch mm

050 10 273.0 8 219.1 6 168.3

080 12 323.9 10 273.0 8 219.1

142 16 406.4 12 323.9 10 273.0

210 16 406.4 14 355.6 12 323.9

250 16 406.4 14 355.6 12 323.9

Note:

EVSZ = Evaporator Shell Size; S = Short Shell, L = Long

Shell, E = Extended Shell

22 TCVHE-SVX04D-EN

Installation Water Piping

RELEASED 10/Mar/2020 06:59:20 GMT

Loading...

Loading...